12 I-Class

resulting in a darker image. Conversely, if the image is too dark, reduce this

value.

The final method is to change the ‘Print Control / Print Speed’ menu setting

(also selectable as ‘Print Speed’ in most software programs). Changing the

print speed changes the amount of time the media is under the printhead.

Slower speeds allow more time and control for energy transfer, while faster

speeds will increase throughput, but may require higher heat settings.

;

Note: Heat and Speed settings can be overridden by host software

commands.

You will find that printing barcodes and detailed images on less expensive direct

thermal and thermal transfer media at higher speeds can be tricky. At one heat

setting, the images will fade and at the next higher heat setting, the images will

bleed. This is because the reaction temperature of the media is so high that at

higher rates of speed, it cannot react fast enough. To print fine images at higher

speed, media with lower reaction or release temperatures are required. On the

slower end of the print rate settings, crisper images are possible because the

media is not being stretched beyond its limits.

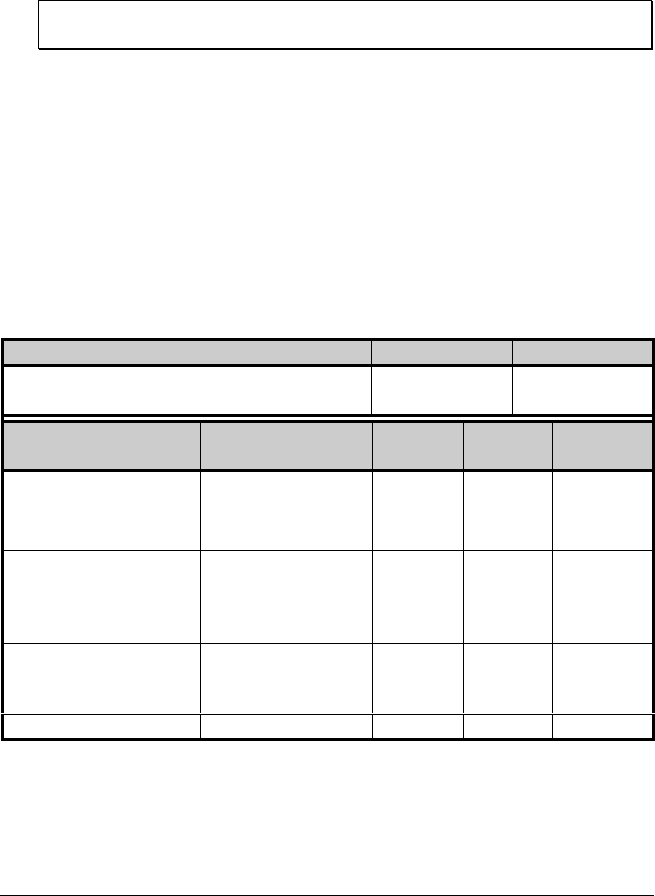

The following table is intended for reference only (for specific application

information, consult your media specialist or a Datamax Media Representative).

Direct Thermal Media Type Print Speed* Print Energy

Fasson 300 HD Direct Thermal Facesheet

Fasson 300 MD Direct Thermal Facesheet

10-12**

Medium

Thermal Transfer

Media Type

Ribbon

Type

Print

Speed*

Print

Energy

Image

Durability

Great Label TTL GPR Plus

MaxWax

IIMAK Versamark

10-12** Medium Medium

Coated Paper,

Uncoated Paper, Tag

Stock, Some Films,

Some Synthetics

Wax 2 - 10 Low Low

Coated Paper, Glossy

Paper, Tag Stock,

Some Synthetics, Films

Wax/Resin 2 - 8 Medium High

Synthetics, Films Resin 4 - 6 High High

*Values given in inches per second (IPS)

**Highly recommended for optimum print quality at speeds above 10 IPS.