INSTALLATION (continued)

1--2

Connecting Power Conductors

A Wiring Diagram is furnished with the ATB. All wiring

must be made in accordance with the local codes. After

the power cables have been tested, connect them to the

appropria te terminal lugs on the Bypass Switch as shown

on the wiring diagram provided with this ATB. Make

sure that the lugs provided are suitable for use with the

cables being installed. Standard terminal lugs are

solderless screw type and will accept the wire sizes listed

on the drawings provided with the ATB. Be careful when

stripping insulation from conductors; avoid nicking or

ringing the conductor. Remove surface oxides from

conductors by cleaning with a wire brush. Follow

conductor manufacturer’s instructions when aluminum

conductor is used. Apply joint compound to conductor,

then carefully wipe away excess compound. Tighten the

cable lugs to the torque specified on the rating label.

Be sure that the N ormal and Emergency power

connections are in proper phase rotation.

!

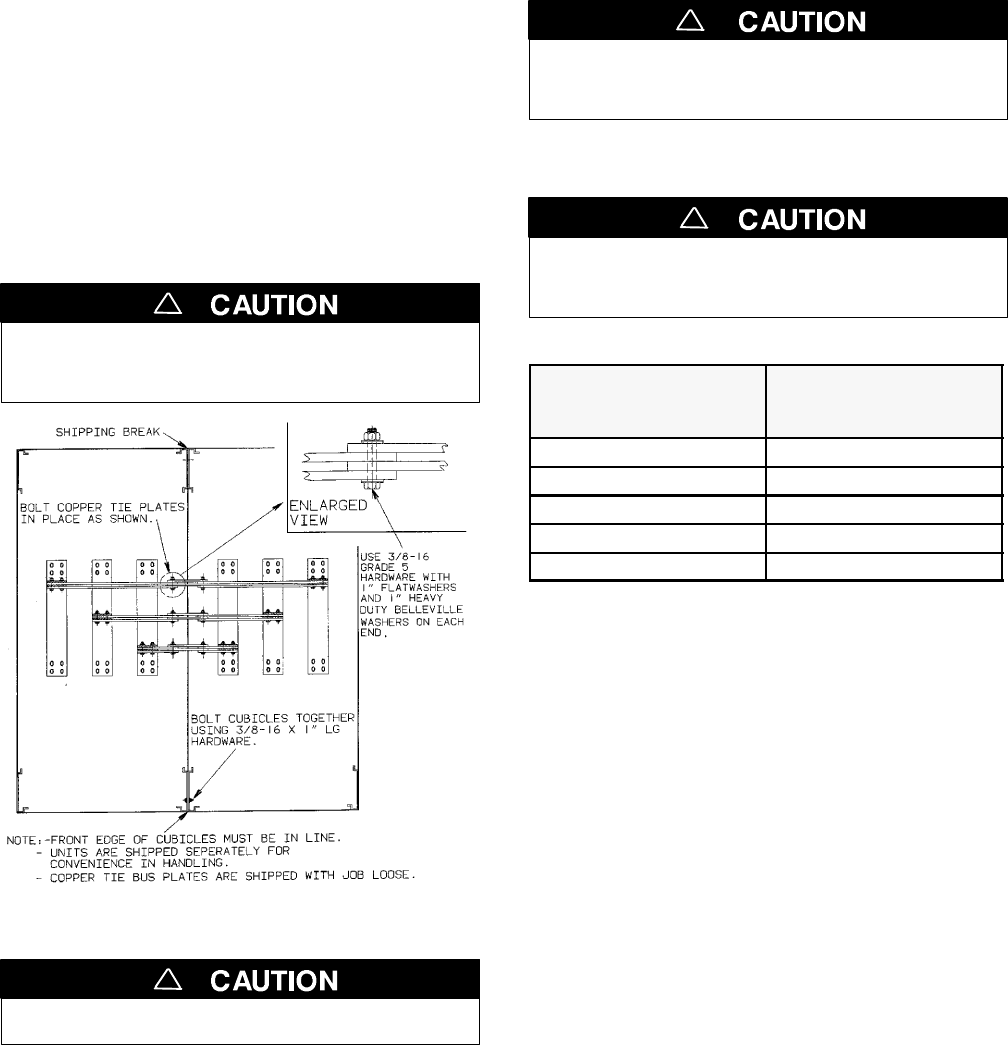

Figure 1–1. Bus tie plates (top view).

See job specific drawings supplied with A TB.

!

Bus Connections

If bus connection is used, use SAE grade 5 hardware to

connect bus to appropriate terminal plates on bypass

switching device. Wipe off bus surfaces before they are

joined. If bus is dirty, gently clean surfaces with a

non-flammable solvent. Avoid touching cleaned surfaces.

Do not breathe cleaning solvent vapors.

!

UseSAEgrade5hardwareandtightentheboltedjoints

tothetorquespecifiedinTable2-1.

The reliability of the connection depends

on how clean and how tight the joint is.

!

Table 2-1. Tightening torque values for bolted j oints.

Bolt Diameter

(Grade 5 hardware)

in in ches

Recommended

Tightening Torque

in f oot pounds

5/16 12

3/8 20

1/2 50

5/8 95

3/4 155

Harnesses

All interna l connections are made at the factory. The

bypass switch, transfer switch, and control panel are

joined together by an interconnecting wire harness. The

disconnect plugs are already engaged on enclosed

switches. For ope n–type swit ches, the plugs must be

engaged after installation is completed. Align harness

plugs with sockets in the control and push them together

until they are secure.

Engine Starting Contacts

and Auxiliary Circuits

The engine control contact signal connectio ns and

auxiliary circuits are located on terminal block TB as

shownontheWiring Diagram provided with the ATB.

Connect the signal wires to the appropriate terminals.