EPSON Stylus PHOTO 810/820/830 Revision B

Operating Principles Overview 29

2.1.2 Printhead

The Printhead uses the same U-CHIPS type as the previous printer (Stylus COLOR

680), and makes it possible to perform multiple shot printing and variable dot printing.

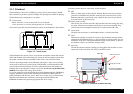

The Printhead nozzle configuration is as follows.

Nozzle layout

Black: 48 nozzles x 1row (nozzle pitch of row: 1/120 inch)

Color: 48 nozzles x 1 row/col (nozzle pitch of row: 1/120 inch)

The nozzle layout when viewed from the back surface of the Printhead is shown below.

Figure 2-2. Nozzle layout

The Printhead has the electric poles to store the ink consumption amount data into the

CSIC chip mounted on the ink cartridge. By storing the ink consumption amount data,

this printer can detect the ink consumption status, such as ink low/end condition.

The basic operating principles of the Printhead, which plays a major role in printing,

are the same as the previous printer (Stylus COLOR 680); on-demand method which

uses PZT (Piezo Electric Element). In order to uniform the ejected ink amount, the

Printhead has its own Head ID (13 digits code for this Printhead

for Stylus Photo 810/

820/830

) which adjusts PZT voltage drive features.

So, you are required to store the Head ID pasted on the Printhead into the EEPROM by

using the Adjustment program when replacing the Printhead, the Main board, the

Printer mechanism with new one. (Note : there are no resistor arrays to determine the

Head ID on the Main board.) And then, based on the stored Head ID into the

EEPROM, the Main board generates appropriate PZT drive voltage.

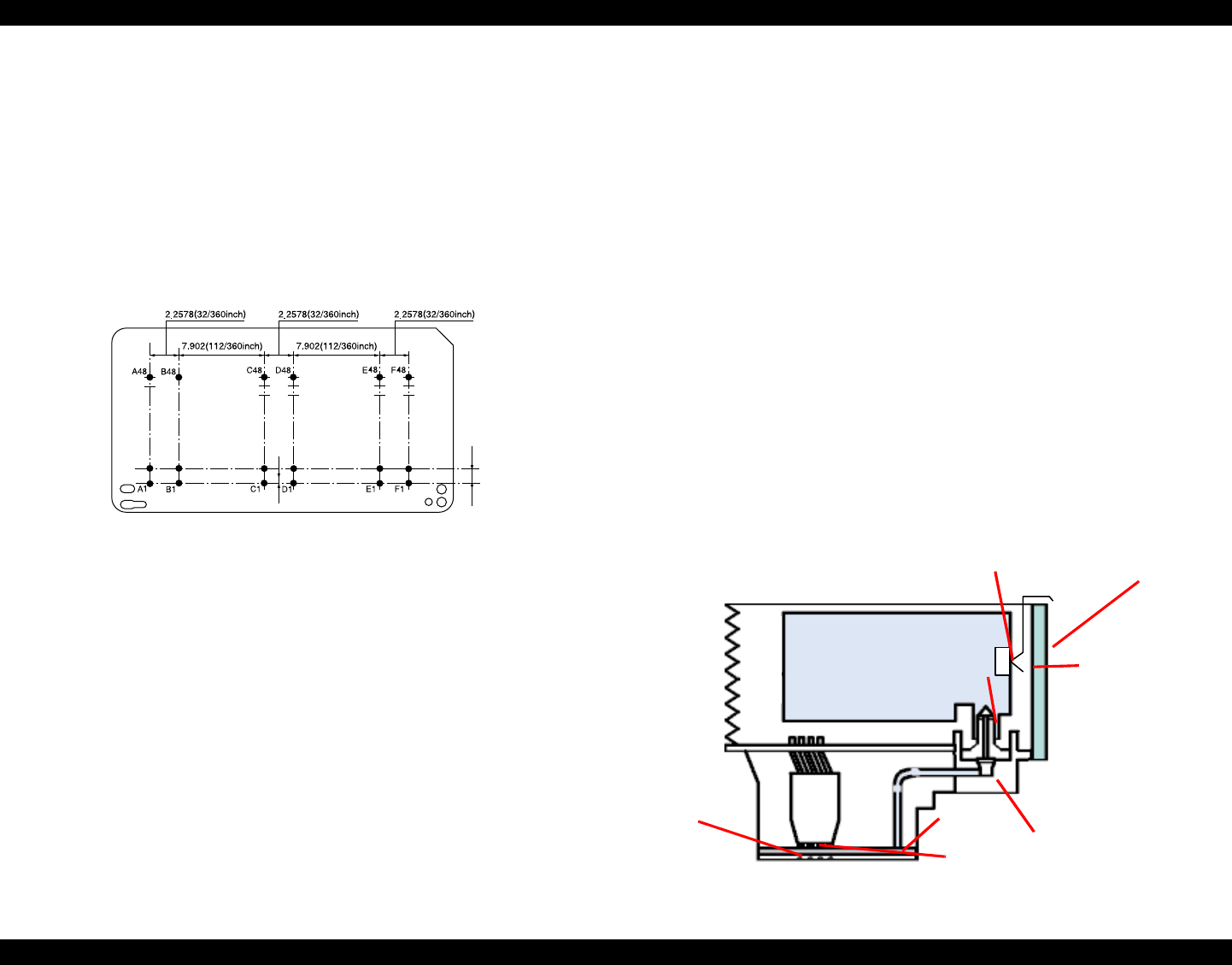

Following explains the basic components for the Printhead.

PZT

PZT is an abbreviation of Piezo Electric Element. Based on the drive waveform

generated on the Main board, the PZT selected by the nozzle selector IC on the

Printhead pushes the top of the ink cavity, which has ink stored, to eject the ink

from each nozzle on the nozzle plate.

Electric poles for CSIC

This electric poles connects the CSIC chip mounted on the ink cartridge. By using

this poles, current ink consumption amount data is red out from the CSIC chip.

And, the latest ink consumption amount data is written into the CSIC chip.

Nozzle Plate

The plate with nozzle holes on the Printhead surface is called Nozzle Plate.

Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge needle is

absorbed into the Printhead, there is a great possibility of causing nozzle clog and

disturbance of ink flow, and alignment failure and dot missing finally. To prevent

this problem, a filter is set under the cartridge needle.

Ink Cavity

The ink absorbed from the ink cartridge goes through the filter and then is stored

temporarily in this tank called “ink cavity” until PZT is driven.

Figure 2-3. Printhead sectional drawing

Nozzle selector board

Needle

Ink cartridge

Filter

Cavity

PZT

Nozzle plate

CSIC chip

Elect ric poles for CSIC

* Head ID for the Printhead

is stored to the EEPROM.