GBC 1264WF/1244WF Operation Manual

© 2006 General Binding Corporation Page 30

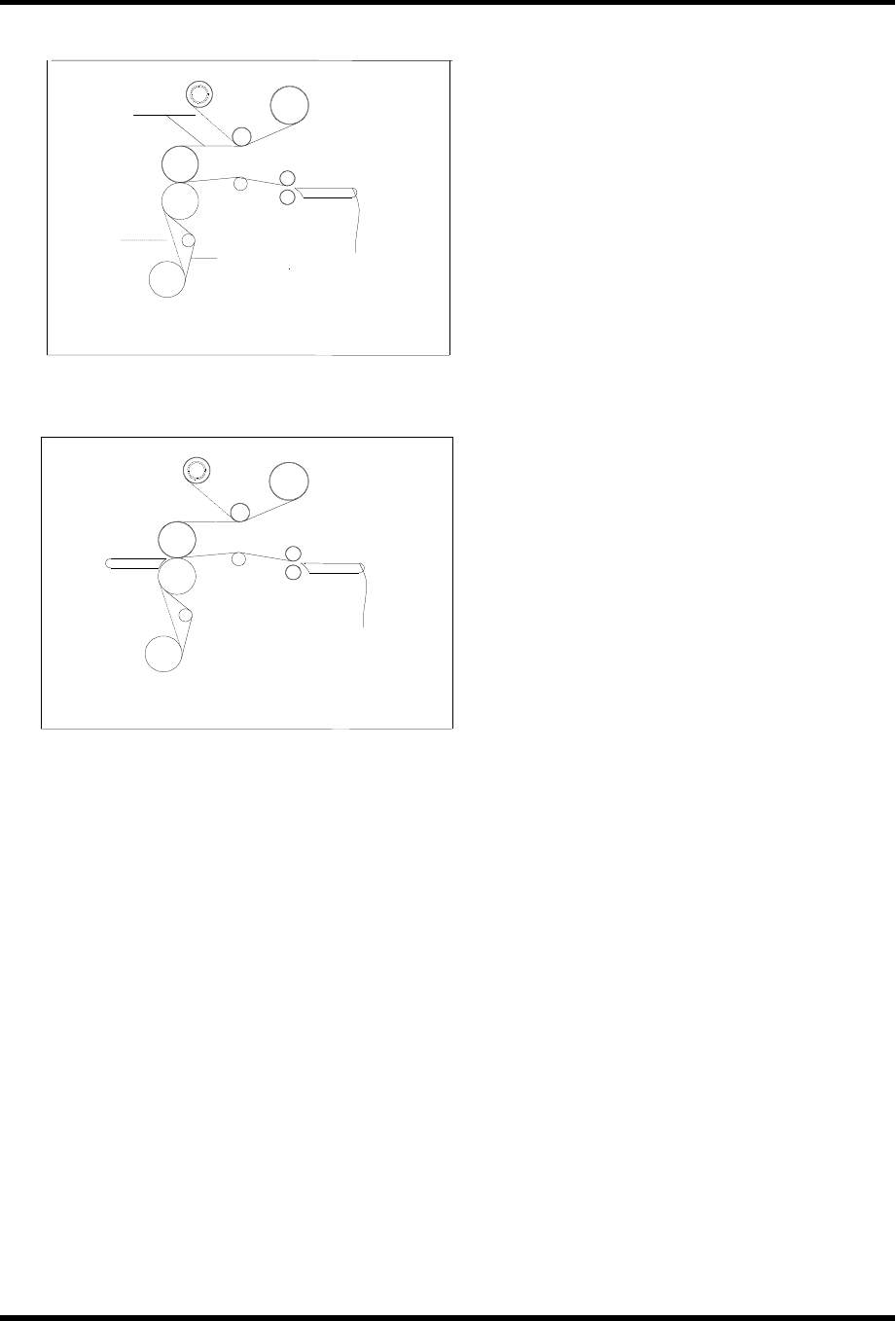

Fig. 11

Fig.12

Method for Tacking New Film to Existing Film

The following describes a method for loading film whereby

the existing film present on the heat rollers may be used in

place of the threading card to draw the new film through

the laminator. The adhesive of the existing film must be

tacky or liquefied. Leading edges of the new film will be

overlapped onto the tacky adhesive of the old film. The

existing film and the new film will be pulled through the

laminator together.

CAUTION: Do not cut yourself

CAUTION: Be careful not to cut any of the rollers!

1. Cut (1) remaining top film web between the idler bar

and heat roller. Cut (2) the film web between the lower

film supply and the idler bar (Figure 11).

CAUTION: Be careful not to cut any of the rollers!

2. Remove the feed table down.

3. Do not allow the adhesive side of the film to contact

the heat or pull rollers. Liquefied or tacky adhesive

deposited on heat rollers will require the rollers to be

cleaned per the section tilted.

4. Replace both the top and bottom rolls of film with new

rolls. Ensure the adhesive side is facing out.

5. Pull the film around the idler bars, with the exception

of PSA mounting adhesives without a release liner.

6. Tack the new film to the existing film on the heat

rollers. For PSA film, attach the release liner to the

rewind tube

7. Use the footswitch to advance the film into the heat

roller nip.

8. Observe the film being pulled through the laminator to

assure that the remaining existing film and the new

films are advancing concurrently. Any separation

between the films will require stopping the motor

immediately and the situation corrected.

9. Press STOP once the newly threaded film has

completely exited the pull rollers.

.......a PSA film or mount adhesive

(2)

(1)

(2)

.......a PSA film or mount adhesive