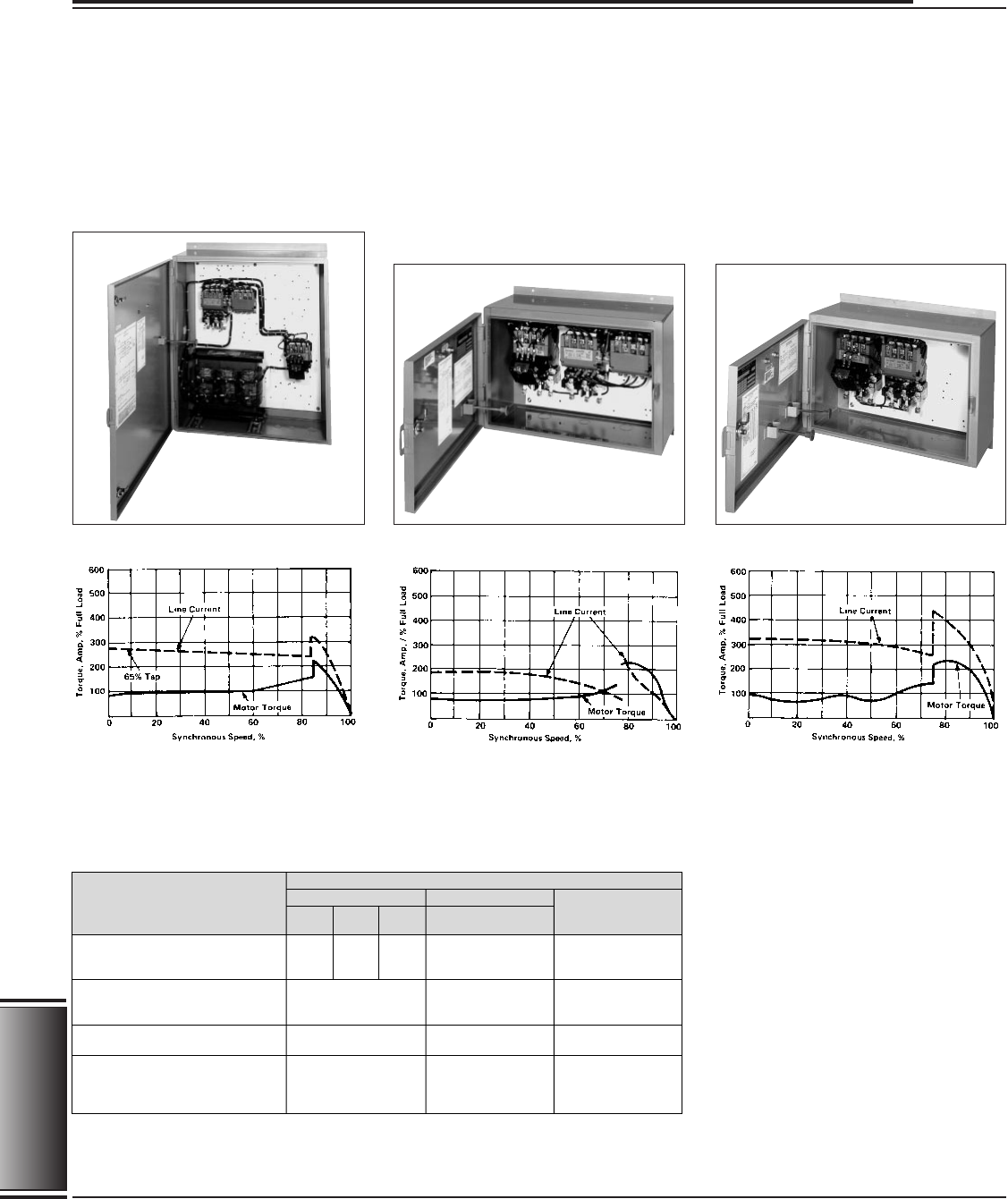

Auto Transformer Starter

Operation

At starting, the auto transformer reduces

motor terminal voltage to 50, 65, or 80

percent of line voltage. For a timed inter-

val, a segment of the transformer coil is

connected in series (as an inductor) with

the motor. Then a contactor automatically

connects the motor across the line and

shorts out the inductor.

Wye Delta Starter

Operation

Initially the starter connects the motor

on a Wye connection, reducing voltage

across the winding to approximately

58 percent. Starting torque and current

is about 33 percent of across the line.

After a time delay the motor is

connected Delta.

Part Winding Starter

Operation

Part winding starters apply starting

current in timed steps to part winding

motors. Two step controllers apply volt-

age through one starter to one motor

winding followed by the second starter

which connects voltage to the second

winding. The timer may be adjusted to

automatically close the second controller

at the most favorable time to minimize

voltage fluctuations.

306 CSI Section 16160

Siemens Electrical Products and Systems

Specification Guide

AC Controls

15

General

AC Controls

Reduced Voltage Starters — Electromechanical

Typical Speed Torque Curves

Auto Transformer Starter

Wye Delta Starter Part Winding Starter

Table 15.35

of Reduced Voltage Motor Starting

Comparison of Various Electromechanical Methods

50%

Tap

25%

First in order of

smoothness

30 seconds

Based on NEMA

medium duty

transformers

65%

Tap

80%

Tap 2 Step Wye(Star) Delta

Reduced Voltage Starting

Autotransformer

ቢ

Part Winding

Characteristics

Starting current drawn from line as % of

that which would be drawn upon full

voltage starting

ባ

Starting torque developed as % of that

which would be developed on full

voltage starting

Smoothness of acceleration

ብ

Allowable accelerating times (typical)

ቢ

Closed Transition.

ባ

Full voltage start usually draws between 500% and 700% of full load.

ቤ

Approximate values only. Exact values may be obtained from motor manufacturer.

ብ

Solid state starters provide the smoothest starting characteristics.

42% 64% 33%

33%

64%

ቤ

45%

ቤ

Third in order of

smoothness

2-3 seconds

Limited by

motor design

45-60 seconds

Limited by

motor design

Second in order of

smoothness

Increased slightly with

speed