SJ100/L100 / PID / 14

4. EXAMPLE OF ACTUAL APPLICATION

You can find in this chapter some typical setting examples for actual applications.

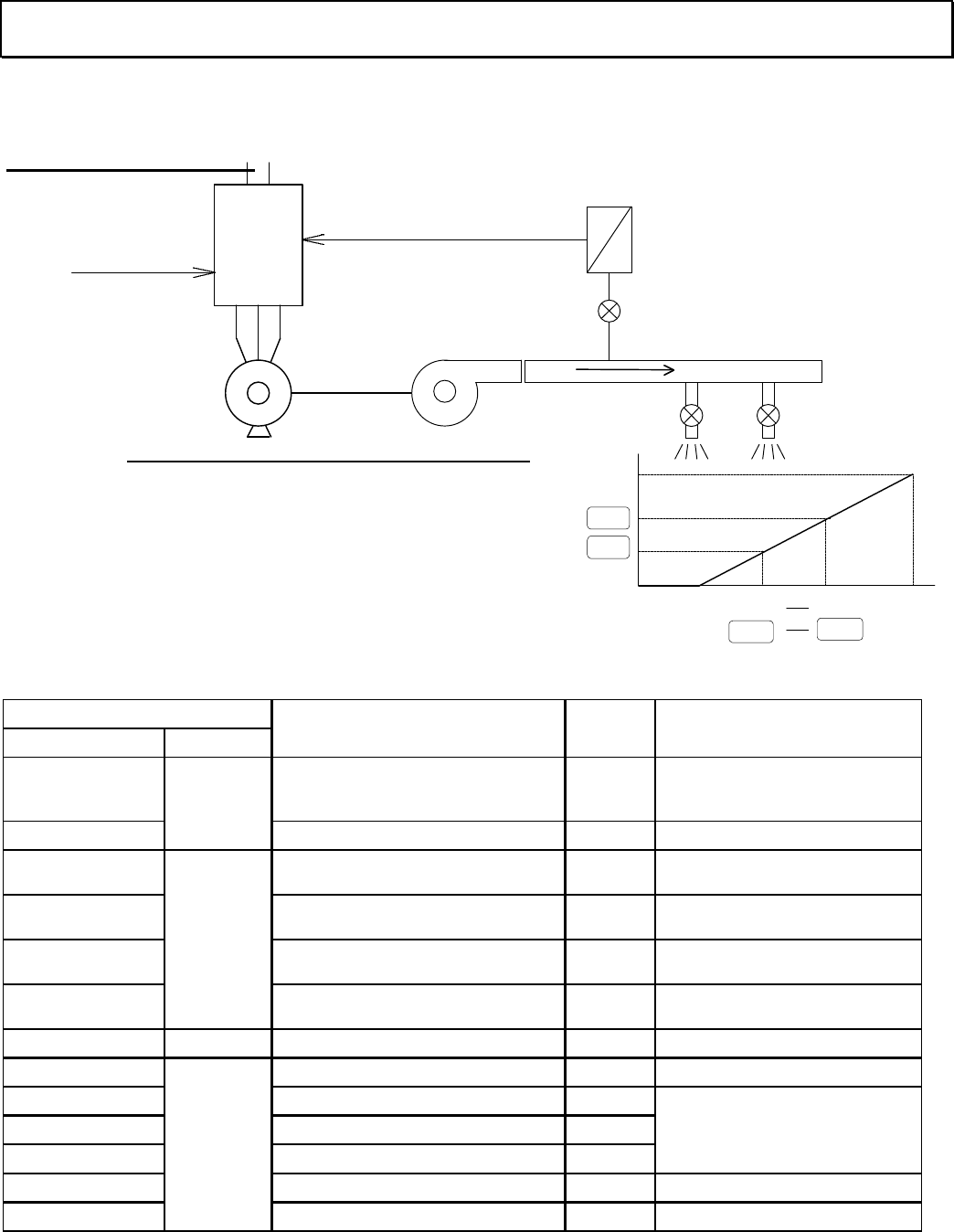

4-1 Constant Flow Control

In this case (targets are 150m

3

/min &

300m

3

/min), the settings would be as follows:

Function Number

Function Name

Input

Remarks

Integrated Operator

DOP, DRW Under PID Control Mode

Data

F01

Monitor

mode

Target 0

150

Directly input “150 [m

3

/min]”

because scale conversion ratio is

given

A01

Target input origin setting

02

Operator

A11 F31

Feedback value input corresponding %

for lower acceptable level

0

0%

A12

Feedback value input corresponding %

for upper acceptable level

100

100%

A13

Feedback value input

for lower acceptable level setting

20

20%

A14

Feedback value input

for upper acceptable level setting

100

100%

A21 F11

Target 1

300

300 [m

3

/min]

A71 F39

PID mode selection

01

PID mode ON

A72

P-gain adjustment

-

Depends on each application

A73

I -gain adjustment

-

A74

D-gain adjustment

-

A75

PID scale conversion factor setting

5.0

100% when 500 [m

3

/min]

A76

Source of feedback signal selection

00

Feedback from OI-L terminal

L100/

SJ100

Target

Feedback

Transducer

4 - 20mA

(500m

3

/min when 20mA)

Flow sensor

Flow : 150m

3

/min or 300m

3

/min constant

Pump

Motor

Fig. 4-1 Example of Constant Flow Control

4 bit digital signal

300m

3

/min

500m

3

/min 100

150m

3

/min

Feedback value range setting

%

0

20mA

4mA0

100%

20%0

10.6mA

53%

60

30

5.8mA

29%