NovaJet PRO 600e User's Guide

4-6 Printer maintenance and storage

Periodic cleaning

To assure the best quality printing, you should clean the cartridges and service station daily for

heavy use and once a week for moderate use. In addition, you should wipe any areas of the

printer exposed to ink and the slide shaft using a lint-free cloth moistened with water.

Note: Do not lubricate the print shaft! Keep it clean using a clean cloth and rubbing alcohol.

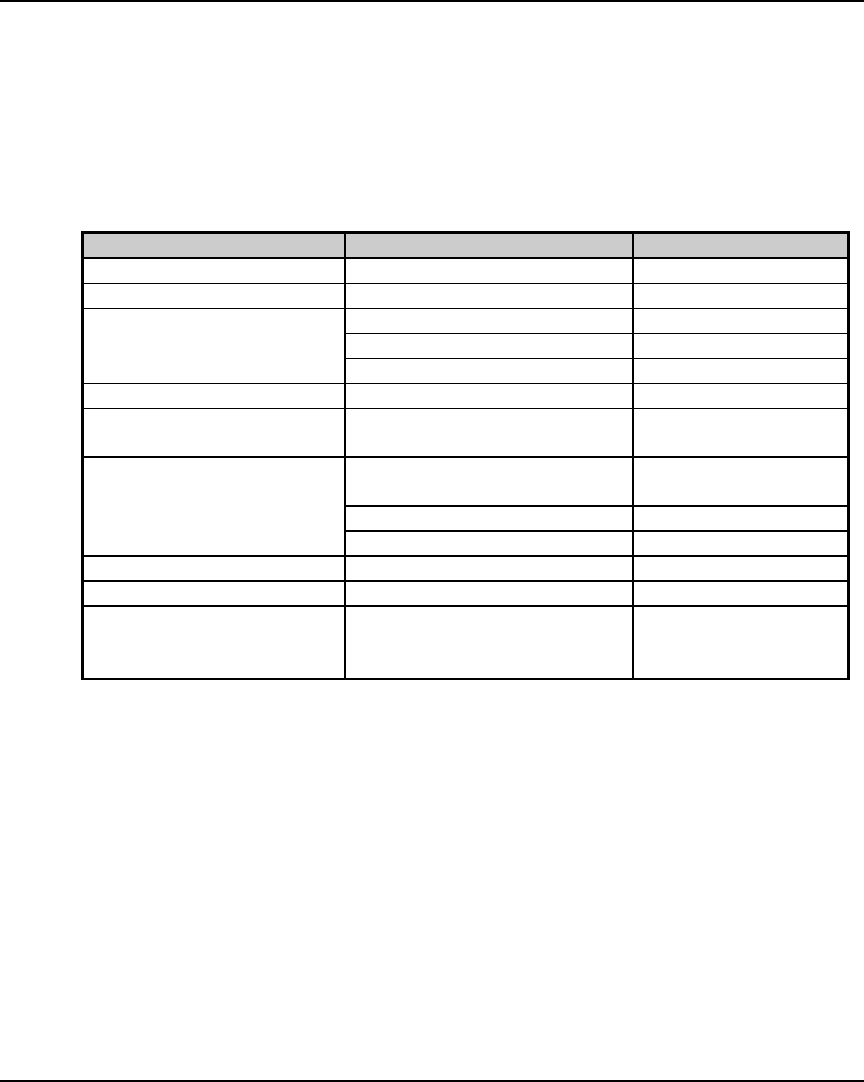

The table that follows identifies periodic cleaning which you can perform to keep your printer in

top operating condition.

Interval Component Cleaning Agent

Immediately

Any - clean up ink spills Distilled water

Daily, as needed

Service station seals and wipers Distilled water

Monthly

Slide shaft Isopropyl alcohol

Encoder strip top and bottom Distilled water

Cartridge jet area Distilled water

Semiannually

External areas Distilled water

Twice a month

Pinch rollers and lower drive

rollers

Isopropyl alcohol

Annually

Encoder sensor Canned air or alcohol-

moistened cloth.

Inner platen Distilled water

Carriage Distilled water

As Required

Keypad Industrial Film Cleaner

Other

When a cartridge is changed

or there is a problem with the

prime

Cartridge dimples/flex driver

cables

Isopropyl alcohol

Materials to use for cleaning

• Isopropyl alcohol (industrial grade) • Lint-free soft cloth/paper wipe

• Dry lint-free cloth • Cotton swabs

• Ultrasonic cleaner (if available) • Distilled/Reverse osmosis water (purified water)

• Canned/compressed air.

Components to annually inspect

The following components should be cleaned and inspected for damage on an annual basis and

replaced if necessary.

• Carriage belt • Service station seals and wipers

• Trailing cable • Cutter