TP-6810 11/1348 Section 4 Scheduled Maintenance

4.2 Service Schedule

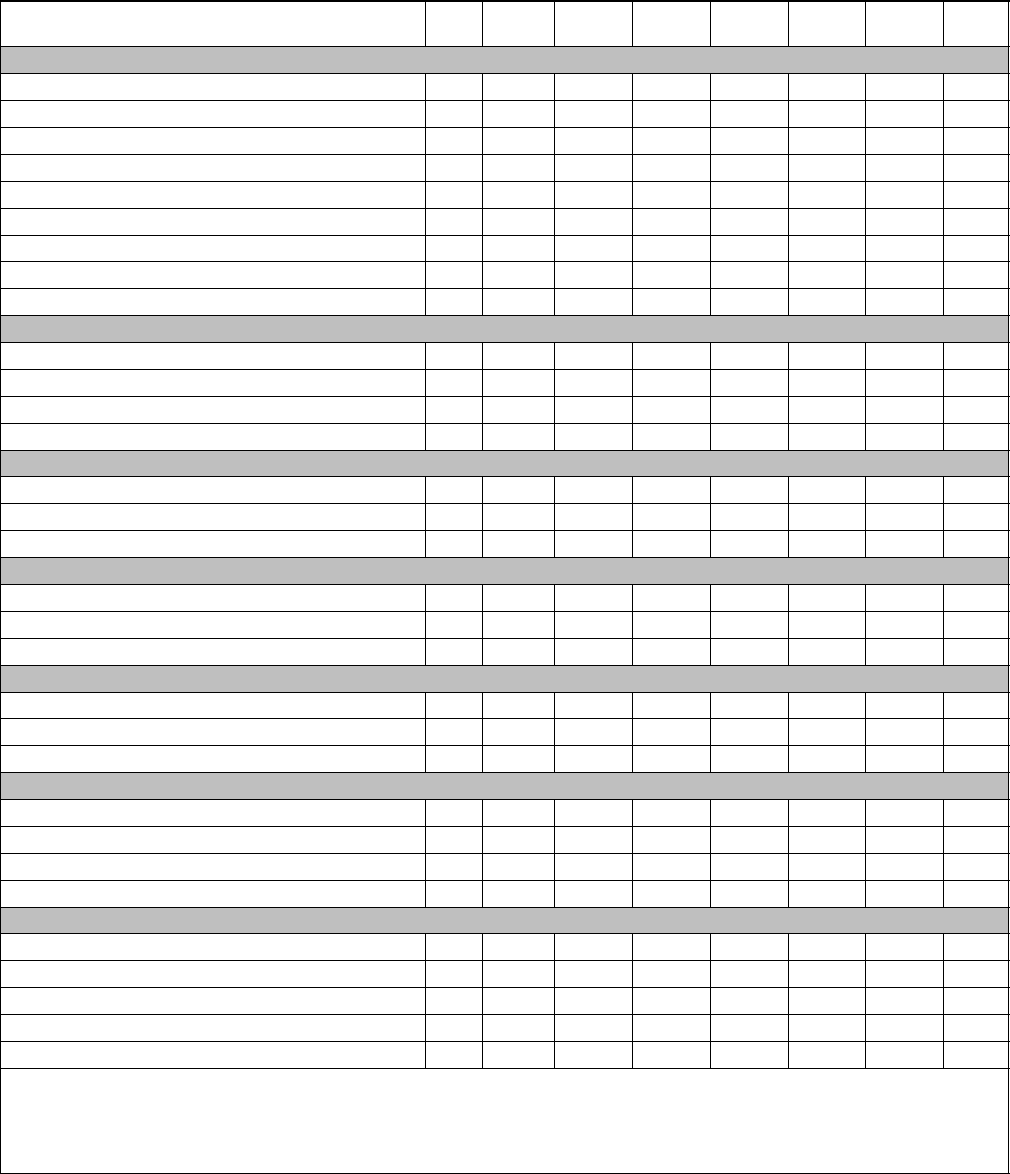

Perform maintenance on each item in the service schedule at the designated intervals for the life of the generator set.

Operation Daily

Every

100 Hr.

Every

150 Hr.

Every

400 Hr.

Every

1000 Hr.

Every

1500 Hr.

Every

2000 Hr.

As

Req’d

GENERAL MAINTENANCE

Check for fluid leaks X

Check coolant level * X

Check engine oil level X

Check all bolts and nuts for tightness ]

X X X

Change engine oil and filter [

X

Check fuel system for leaks ]

X

Check belts and belt tension X

Inspect wiring for cuts, abrasions, or corrosion X

Inspect vacuum lines and fittings X

AIR INTAKE SYSTEM

Inspect and clean air cleaner element [

X X

Replace air cleaner element [

X X

Check air induction for leaks X

Check intake manifold for vacuum leaks X

COOLING SYSTEM

Inspect and clean radiator exterior ]

X X

Replace engine coolant w

X

Inspect coolant hoses X

ELECTRICAL SYSTEM

Check battery charge and fluid level ]

X X

Inspect electrical system X

Clean battery cables ]

X

EXHAUST SYSTEM

Inspect exhaust manifold for leaks X

Inspect exhaust piping for leaks X

Check HEGO (oxygen) sensor connections and wires X

FUEL SYSTEM

Check fuel shutoff valve for leaks and function X

Check fuel regulator pressure X

Test fuel lines for leaks X

Inspect/drain vaporizer for oil buildup X

IGNITION SYSTEM

Check spark plug wires for cuts, abrasions, or hardening X

Clean secondary ignition coil wires X

Replace distributor cap and rotor X

Replace spark plugs X X

Replace spark plug wires X

* Check engine coolant condition and protection, hoses, and clamps annually (prior to cold weather).

[ More frequent intervals may be required in dusty or dirty operating conditions.

] Seasonal or as required.

w Long-life coolant is recommended. When long-life coolant is used, the change interval is 5000 hours or 5 years. Do not mix coolant

types.