TP-6810 11/1352 Section 4 Scheduled Maintenance

4.6.2 Coolin g System Inspection

To prevent generator shutdown or damage because of

overheating:

D Keep the cooling air inlets clean and unobstructed

D Inspect the radiator’s exterior for obstructions and

remove dirt and foreign material with a soft brush or

cloth to avoid damaging the radiator fins.

D Check the hoses and connections for leaks and

replace any cracked, frayed, or spongy hoses.

D Check the condition and tension of the radiator water

pump belt(s).

D Check the rubber seal of the radiator’s pressure cap

and replace a cracked or deteriorated cap. Remove

dirt and other debris from the pressure cap and filler

neck. The pressure cap raises the boiling point of the

coolant, enabling higher operating temperatures. If

the cap leaks, replace it with the same rating type of

cap. Find the pressure cap rating in Figure 4-5.

Item Rating

Pressure cap 97 kPa (14 psi)

Figure 4-5 Pressure Cap Rating

4.6.3 Draining Cooling System

The radiator contains a coolant drain valve to drain the

cooling system. When draining the coolant, remove the

radiator’s pressure cap, which will allow the entire

systemto drainand willprevent airpockets fromforming

and restricting coolant passage to the block.

1. De--energize the block heater, if equipped.

2. Remove the pressure cap to allow the entire

system to drain and prevent air pockets from

restricting coolant flow through the engine block.

3. Open the coolant dr ain valve and allow the system

to drain.

4. If the inside of the radiator has mineral deposits or

the used coolant contains dirt or grease, go to

Section4.6.4, Flushingand Cleaning. Ifthecooling

system does not have mineral deposits, refill the

cooling system as instructed in Section 4.6.5,

Filling Cooling System.

4.6.4 Flushing and Cleaning

For optimum protection, drain, flush, and refill the

cooling system at the interval listed in the service

schedule.

Flushing and Cleaning Procedure

1. Flush the system with clean water.

2. Drain, clean, and flush the coolant overflow bottle.

3. Refill the cooling system as instructed in

Section 4.6.5.

4.6.5 Filling Cooling System

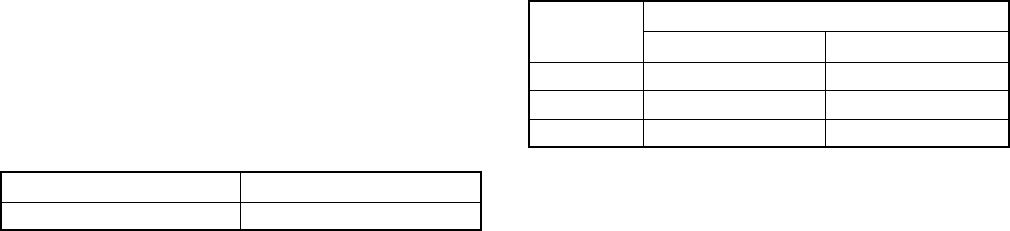

Model

Coolant Capacity, L (qt.)

Generator Set With Block Heater

38RCL 15.5 (16.4) 17.0 (18.0)

48RCL 17.5 (18.5) 19.0 (20.1)

60RCL 17.5 (18.5) 19.0 (20.1)

Figure 4-6 Coolant Capacity

Note: Do not add coolant to a hot engine. Adding

coolant to a hot engine can cause the cylinder

block or cylinder head to crack. Wait until engine

has cooled.

1. Close the radiator’s coolant drain valve and tighten

the hose clamps.

2. Fill the radiator with the recommended coolant

mixture of 50% ethylene glycol and 50% clean,

softened waterto inhibitrust/corrosion and prevent

freezing. The coolant capacity is shown in

Figure 4-6.

3. Operate the engine with the radiator cap removed

until the thermostat opens and the upper radiator

hose becomes hot.

4. Stop the engine and allow it to cool.

5. Add coolant to the radiator to just below the

overflow tube on the filler neck. See Section 1,

Service Views, for the overflow tube location.

6. Replace the radiator’s pressure cap.

7. Maintain the coolant level in the coolant overflow

bottle between the High and Low markings. See

Section 1, Service Views, for the coolant overflow

bottle location.

8. Re--energize the block heater, if equipped.