TP-6810 11/13 51Section 4 Scheduled Maintenance

4.5 Exhaust System

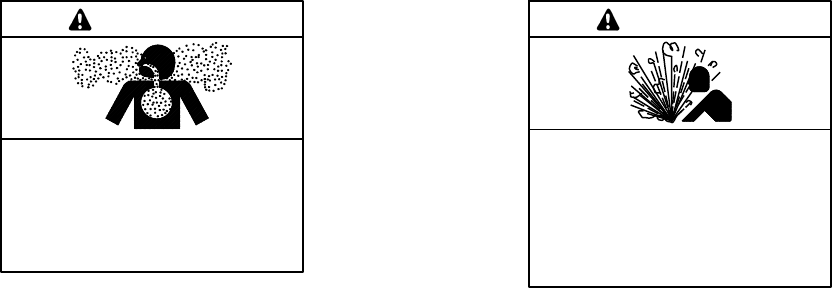

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

WARNING

Carbon monoxide detectors. Carbon monoxide can

cause severe nausea, fainting, or death. Install carbon

monoxide detectors on each level of the building. Locate the

detectors to adequately warn the building’s occupants of the

presence ofcarbonmonoxide. Keepthedetectorsoperational

at alltimes. Periodically test andreplace thecarbon monoxide

detectors according to the manufacturer’s instructions.

At the interval specified in the service schedule, inspect

the exhaust system components (exhaust manifold,

exhaust outlet, exhaust line, exhaust clamps, and

muffler) for cracks, leaks, and corrosion.

Exhaust System Inspection Points

D Checkfor corrodedor brokenmetalparts andreplace

them as needed.

D Check that the exhaust outlet is unobstructed.

D Check the exhaust gas color. If the exhaust is blue or

black, contact your local authorized Kohler distributor/

dealer.

D Visually inspect for exhaust leaks (blowby). Check

for carbon or soot residue on exhaust components.

Carbon and soot residue indicates an exhaust leak.

Seal leaks as needed.

D Check that all covers and doors are undamaged, in

place, and locked.

D Check for the installation and operation of carbon

monoxide (CO) detectors on each level of any

building near the generator set.

4.6 Cooling System

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Allow the engine to cool. Release p ressure from the

cooling system before removing the pressure cap. To

release pressure, cover the pressure cap with a thick

cloth and then slowly turn the cap counterclockwise to

the first stop. Remove the cap after pressure has been

completely released and the engine has cooled. Check

the coolant level at the tank if the generator set has a

coolant recovery tank.

Note: Block heater damage. The block heater will fail

if the energized heater element is not immersed

in coolant. Fill the cooling system before turning

on the block heater. Run the engine until it is

warm and refill the radiator to purge the air from

the system before energizing the block heater.

4.6.1 Checking and Filling Coolant

Maintain the coolant level in the coolant overflow bottle

between the High and Low markings. See Section 1,

Service Views, for the coolant overflow bottle location.

Note: Periodically check the coolant level by removing

the radiator’s pressure cap. Do not rely solely on

the level in the coolant overflow bottle.

Ethylene glycol-based long-life coolant is

recommended. Use a coolant mixture of 50% long-life

coolant and 50% clean, softened water to inhibit

rust/corrosion and prevent freezing. Add fresh coolant

until the level is just below the overflow tube opening.

A coolant solutionof 50%ethylene glycol-basedcoolant

provides freezing protection to --37C(--34F) and

overheating protection to 129C (265F). A coolant

solution with less than 50% ethylene glycol may not

provide adequate freezing and overheating protection.

A coolant solution with more than 50% ethylene glycol

can cause engine or component damage. Do not mix

long-life coolant and conventional coolants. Do notuse

alcohol or methanol antifreeze or mix them with the

specified coolant.