Wiring Inspection 27

10.0 WIRING INSPECTION

1. Verify all power connections are tight.

2. Verify all control wire terminations are tight.

3. Verify all power wires and connections have proper spacing between exposed surfaces, phase-

to-phase and phase-to-ground.

4. Verify that all control wires are run in individual, separate, steel conduit.

Table 1 Power Wiring Terminals - Factory Supplied

UPS Module Rating Connection Type

500 kVA, 6-Pulse Rectifier All power connections are top or bottom cable entry to busbars on the right

side of module.

500 kVA, 12-Pulse

Rectifier

Busbars for DC input, AC output, Neutral and Ground are provided on the

right side of module, with top or bottom cable entry. Rectifier input is top entry

directly to lugs on top of input circuit breaker.

625-750 kVA, standard

models with standard input

Busbars for AC output, Neutral and Ground are provided on the right side of

module, with top or bottom cable entry. Rectifier input is top entry directly to

lugs on top of input circuit breaker. DC input is top entry to bus bars.

750 kVA/675 kW and other

modules with optional

input busbar kit

Busbars for AC output, Neutral and Ground are provided on the right side of

module, with top or bottom cable entry. Rectifier input and DC input are top

entry to bus bars.

Use 75°C copper wire. Select wire size based on the ampacities in Table 310-16 (see Table 3 of this

manual) and associated notes of the National Electrical Code (NFPA 70).

Use commercially available solderless lugs for the wire size required for your application. Connect wire to

the lug using tool and procedure specified by the lug manufacturer.

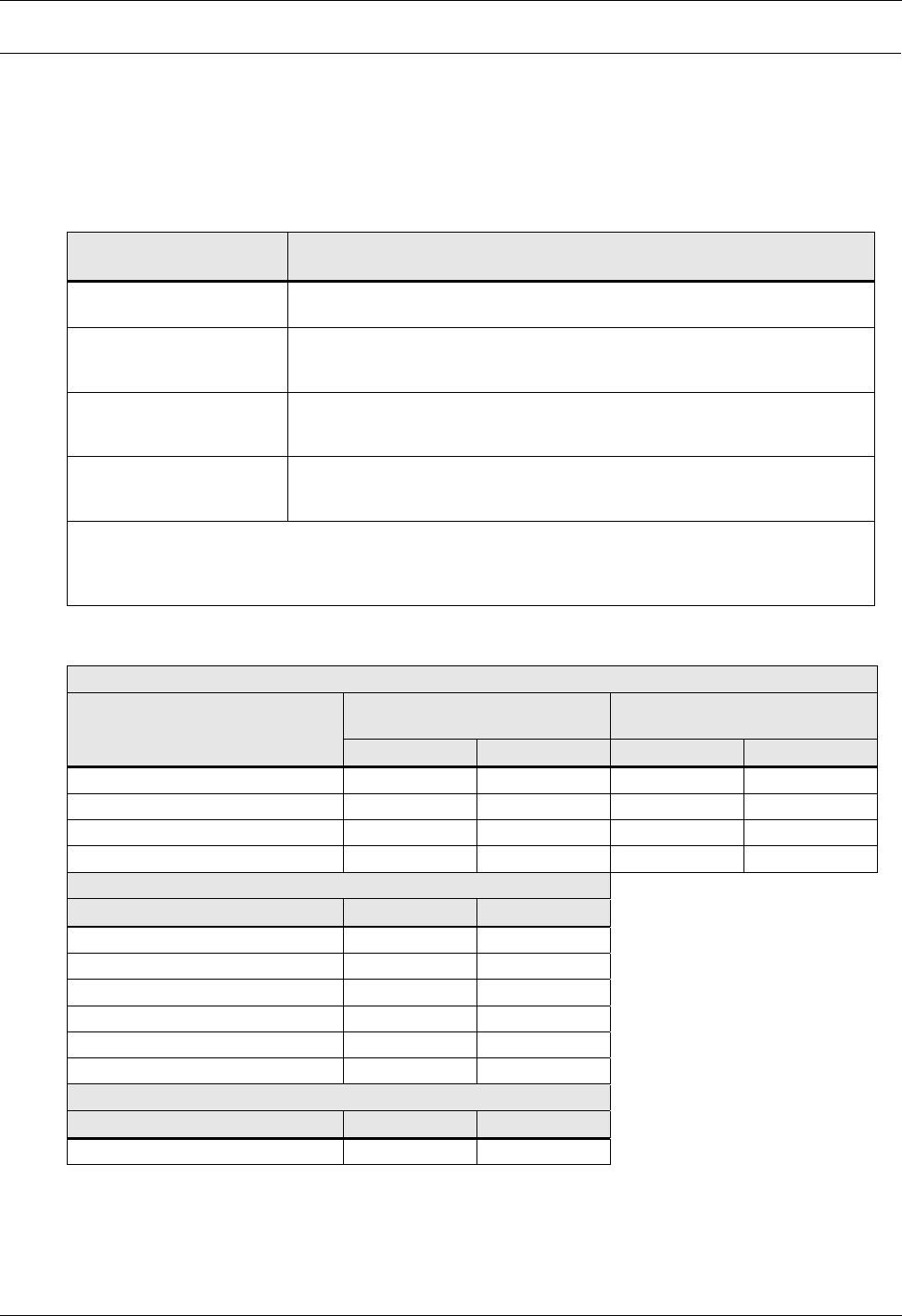

Table 2 Torque Specifications

Nut and Bolt Combinations

Bolt Shaft Size

Grade 2

Standard

Electrical Connections

with Belleville Washers

Lb-in N-m Lb-in N-m

1/4 53 6.0 46 5.2

5/16 107 12 60 6.8

3/8 192 22 95 11

1/2 428 48 256 29

Circuit Breakers With Compression Lugs (For Power Wiring)

CableSizeorRange Lb-in N-m

#6 - #4 100 11

#3 - #1 125 14

1/0 - 2/0 150 17

3/0 - 200 MCM 200 23

250 - 400 MCM 250 28

500 - 700 MCM 300 34

Terminal Block Compression Lugs (For Control Wiring)

AWG Wire Size or Range Lb-in N-m

#22 - #14 3.5 to 5.3 0.4 to 0.6

Use the values in this table unless the equipment is labeled with a

different torque value.