7

3. Install the combined

Plates #1 and #2 (or

Plate 1 with the EXT10)

securely to the Building

Structure following all of

the Local Building/Con-

struction Codes. Use

suitable hardware in ad-

equate quantity and size

depending on the installa-

tion requirements.

Caution: The Projector

together with the mounting brackets

weighs 80 pounds (36.29 kg).

4. Attach the Horizontal Tilting Plate #3 to the previ-

ously combined plates (already installed on ceiling)

using the 1/4-20 inch screws provided. Refer to

Figures 15 and 16. Install two 1/4-20inch screws

with rubber spacers and metal washers part way

into the welded metal studs (indicated #1). The

newly combined Plate 3 provides 10 degrees of

horizontal tilt. After positioning the plate, loosely

tighten the screws.

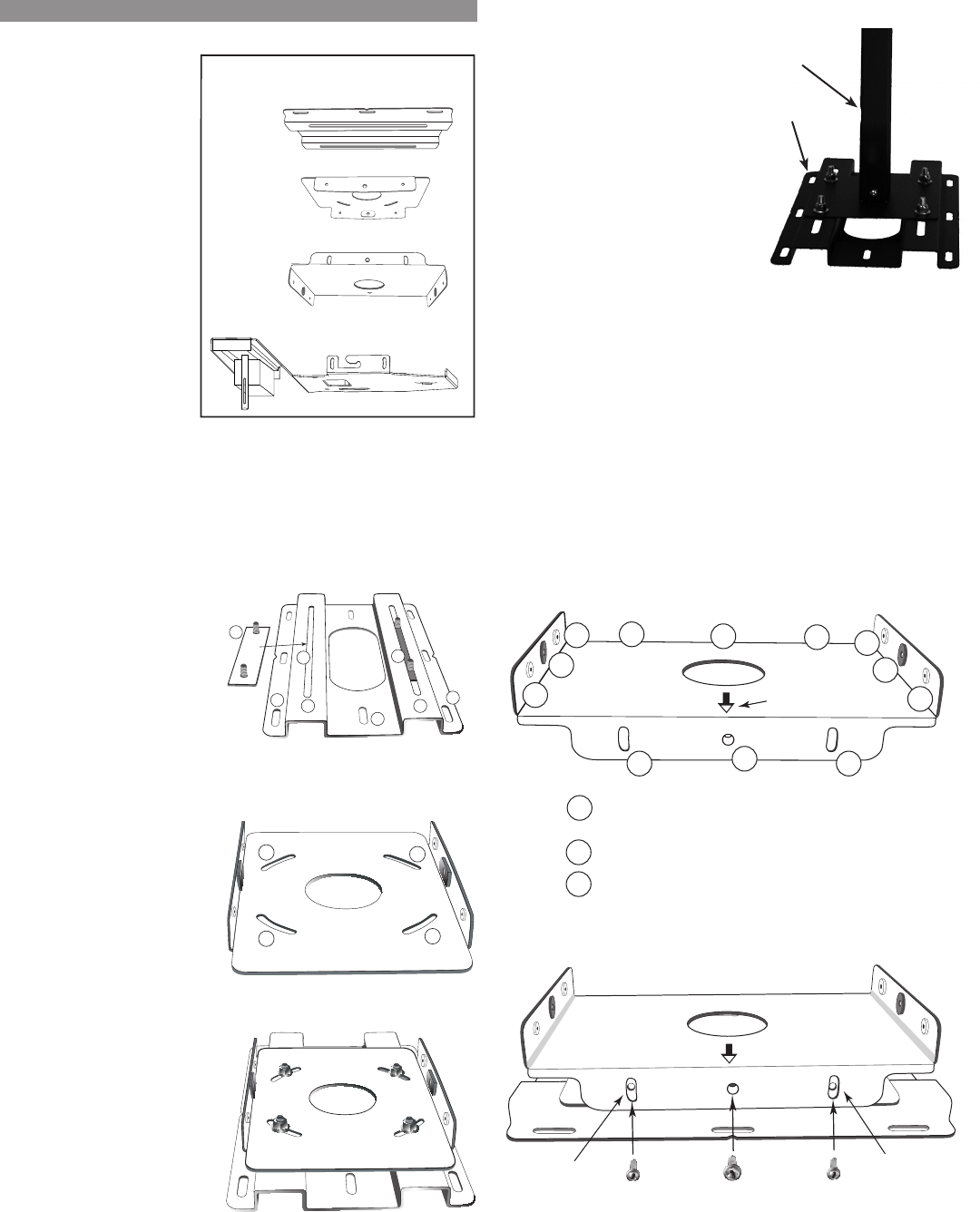

Assemble the MT20 by performing the steps below,

refer to figure 10:

Notes: The MT20 hardware, fasteners, mounting tem-

plate and parts list are located in a separate

shipping carton from the projector. Plate #4

supplied with the LN9101M will be used instead

of the MT20 Plate #4.

1. Insert Base Plate

connectors #1 into

the lateral position-

ing slots #3 from the

underside of Plate 1.

The lateral position-

ing slots will give

you 2-1/4 inches of

lateral adjustment for

projector alignment.

Refer to figure 11.

2. Base plate connector

holes #3 provide 15

degrees of horizontal

rotation adjustment.

Attach horizontal

adjustment Plate 2 to

the projector mount

ceiling Plate 1 using

the four (4) 5/16-18

inch nuts and wash-

ers provided. Refer

to figures 12 and 13.

Note: When the

EXT10 Exten-

sion Pole will

be used, attach

the “Outside

Pole” end to

Plate #1 (instead of Plate #2) using four (4)

5/16-18 inch nuts and washers provided. Refer

to figure 14.

MT20 Assembly

Figure 11

1

2

3

3

4

2

Base Plate Connectors #1

Projector Mount Ceiling Plate 1

Plate 1

2

Ceiling Wire

Access

4

Figure 12

3

3

3

3

Wire

Access

Plate 2

Figure 13

Wire

Access

Plates 1 & 2

Figure 14

EXT10

Plate #1

Figure 16

Plate 3

Tilting

Capability

Tilting

Capability

Figure 10

MB20 and LK1 Mounting Plates

Plate 1

Plate 4 (LK1)

Plate 2

Plate 3

MT20 and LN9101M Mounting Plates

(LN9101M)

Figure 15

Wire

Access

1

1

2

2

2

2

2

2

2

2

3

3

Plate 3

Holes for 1/4-20 inch screws

Holes for 1/4-20 inch screws

Holes for 1/4-20 inch screws with

rubber washer and steel washer

Indicates Forward

Positioning of Mount

1

2

3