NCR RealScan 7882 Installation and Owner Guide

497-0419630 Release F 09/02

19 of 62

Determining Label Quality

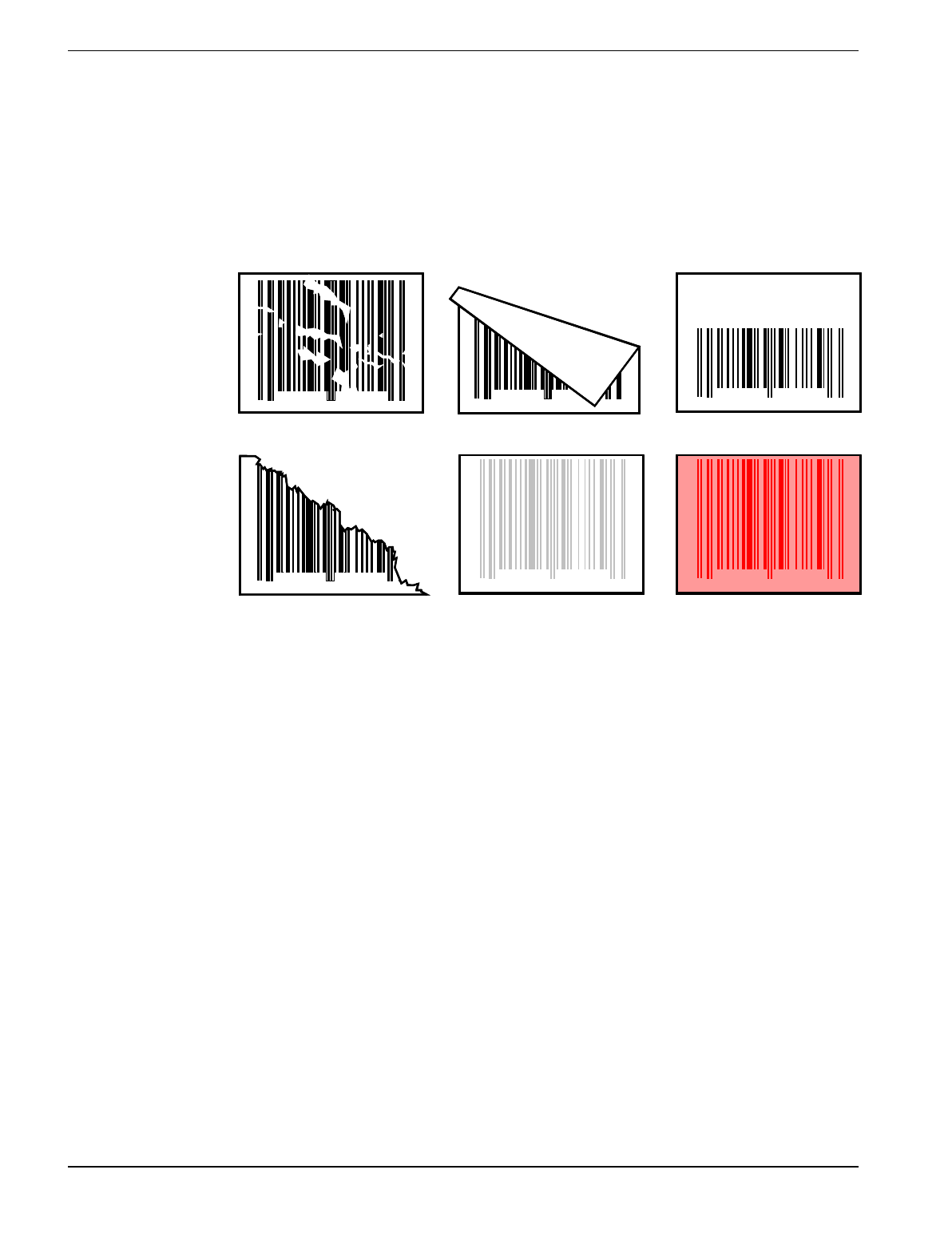

Many labels in a typical retail environment are unreadable. The following illustration

shows some of the common problems. Vendors and printers regularly supply products

to the market with bar codes that are over-printed, under-printed, or truncated. Some

labels have missing margins. Others may be printed around the corners of packages, or

on media not likely to remain flat when picked up.

0

1

2

3

4

6

7

8

5

9

0

6

0

1

2

3

4

6

7

8

5

9

0

6

0

1

2

3

4

6

7

8

5

9

0

6

R0026

0

1

2

3

4

6

7

8

5

9

0

6

0

1

2

3

4

6

7

8

5

9

0

6

0

1

2

3

4

6

7

8

5

9

0

6

Bar Code Scratched

Bar Code Folded

Bar Code Truncated

Bar Code Torn

Poor Color Contrast

Red Bar Code On

Red Background

The readability of a label depends on variables such as size, placement, color, paper

type, ink viscosity, and package coatings. The middle of a printing run can yield

erroneous labels due to the many variants involved. In particular, poor color contrast

and marginal print quality can make a label hard to read.

UPC bar code requirements are identified in the UPC Symbol Specification Manual

that is published by the Uniform Code Council, Inc. Contact the following for a copy of

this document.

Uniform Code Council, Inc.

8163 Old Yankee Road, Suit J

Dayton, OH 45458

Phone: 513-435-3870

Contact the following for information on Code 39 or "3 of 9" bar code labels.

AIM – USA

634 Alpha Dr.

Pittsburgh, PA 15238-2802

Phone: 412-963-8588

EAN bar code requirements are identified in General Specification for Article

Symbol Marking, Copyright EAN-1977.