Theory of Operation

13

3 Theory of Operation

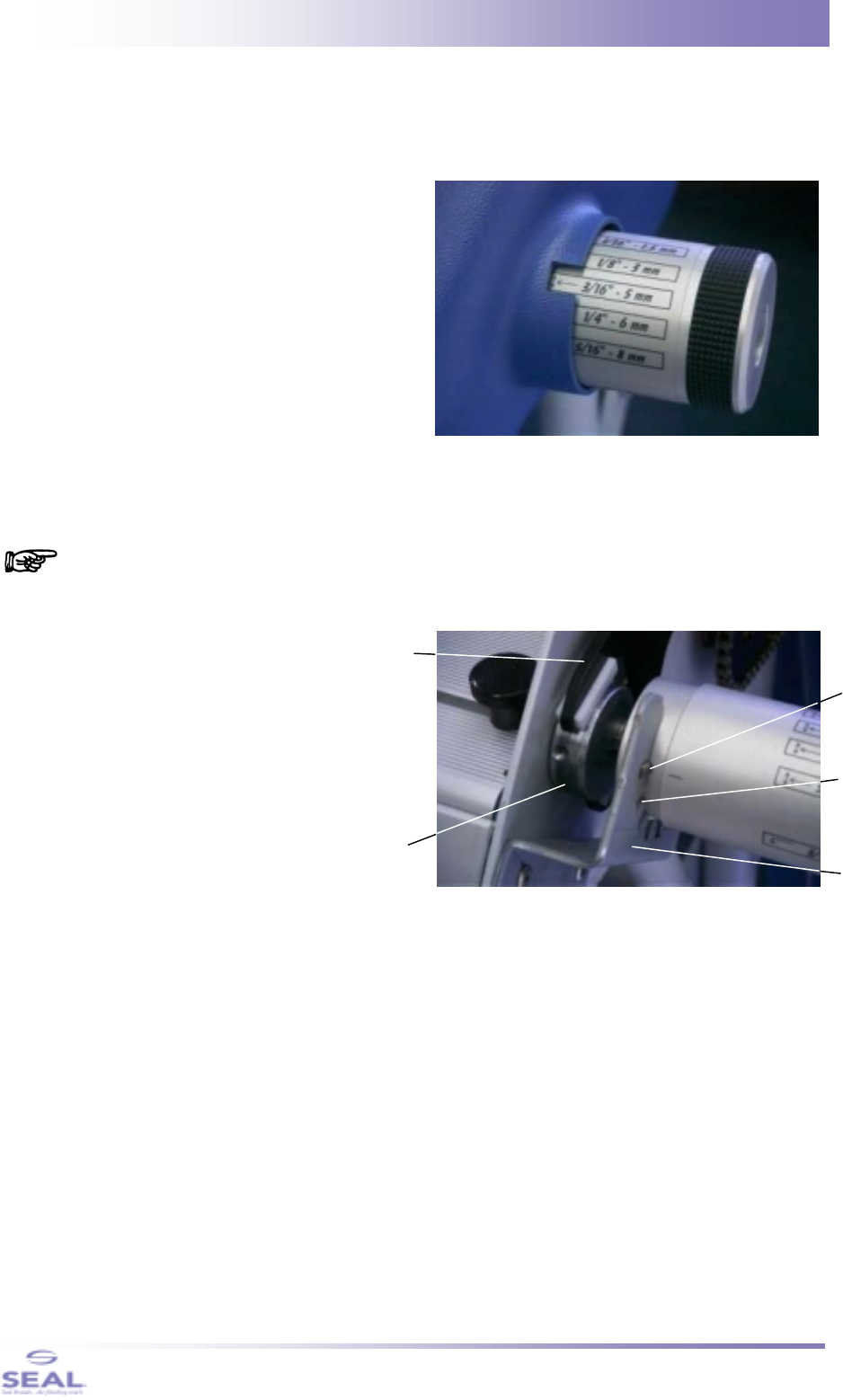

3-1 Control Knob

The Control Knob (see figure 1) is located on the

right hand side of the laminator and is operated

from the front of the machine.

The Control Knob can be operated by pushing it in

approximately 6mm (1/4”) to the left. Once the

knob has disengaged from the stop, it may be

rotated forward or backward (clockwise or counter-

clockwise, viewed from the right hand side of the

unit).

Continue to rotate the knob until the desired nip

setting corresponds with the indicator window at

the base of the knob. Inside the window, the

possible rotation directions are shown. Select the

value that corresponds to the thickness of the material you will be using with the machine.

Releasing the knob so that it moves back to the right and clicks into place will set the rollers for use.

Select the next lower value in case there is no match for the thickness of the used

substrate.

Internal functionality

See figure 2.

Inside the machine, a rod is mounted

between the left- and right-hand framesheets.

The knob is mounted on the rod; it allows

axial movement, but no radial movement.

The knob is provided with a pin (1), that falls

in the indents (2) of a bracket (3). The same

rod is provided with an eccentric (4) on either

side of the machine. These eccentrics push

or pull the arms (5), where the top roller is

mounted in, upward or downward.

3-2 Roller Nip settings

Whenever you mount onto a board, etc., it is important to adjust the rollers to create a gap nearly

equal to the thickness of the board being used. This is done so that anything passing between the

rollers will receive the right amount of pressure and prevent damage to the rubber surface of the roller

(and possibly the board).

1

2

3

4

5

fig. 1

fig. 2