Adjustment Procedures

32

5-5 Drive Chain

Necessary tools: Allen key 4mm, medium flat-head screwdriver.

Approximate time: 8 minutes.

Note: to perform the following adjustments, it is necessary to remove the right-hand side cover first.

See section 4-1: Disassembly / Reassembly Plastic Side Covers.

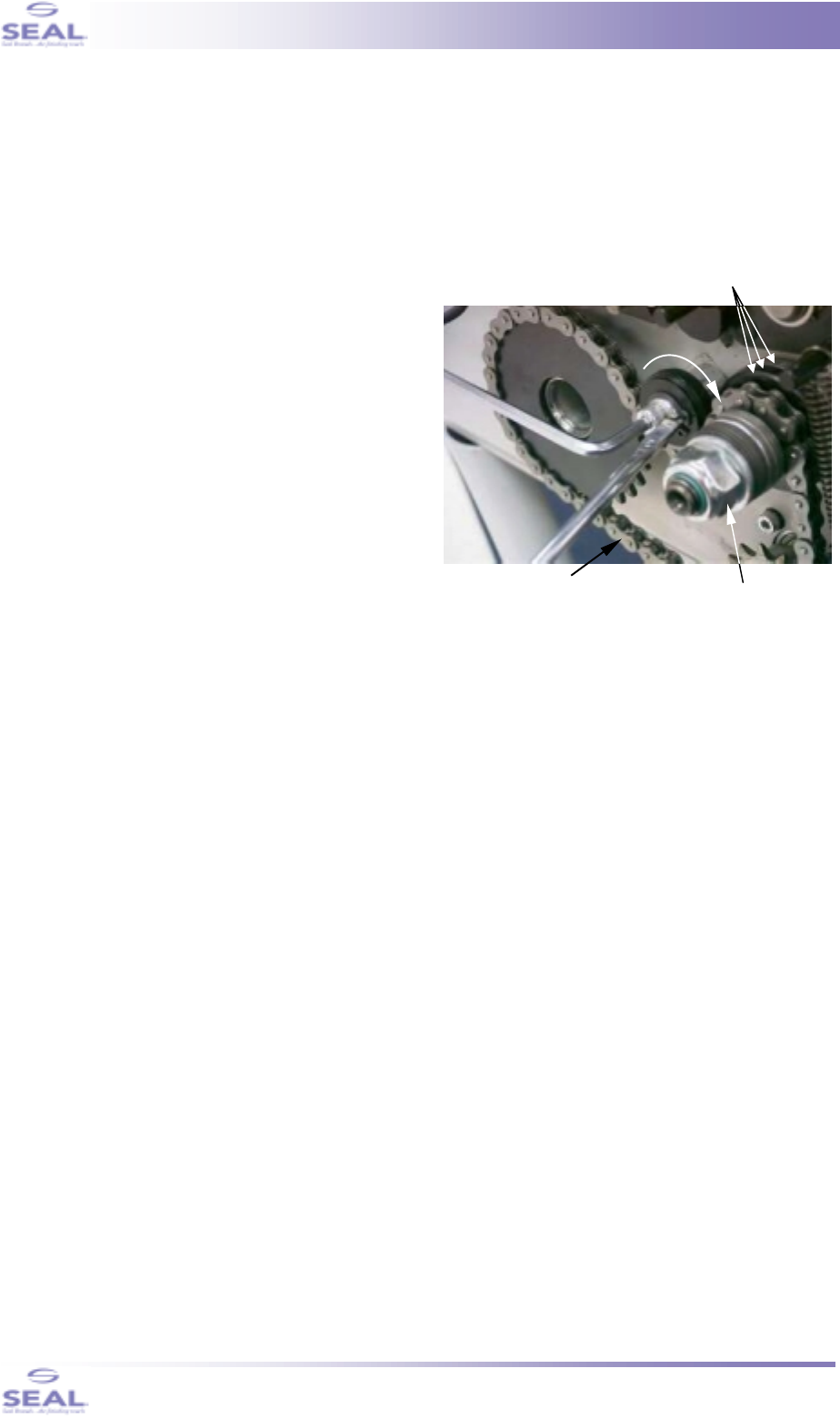

The chain guide ensures that the chain has

sufficient grip on the clutch assembly.

See figure 36. If the lower section of the chain

(black arrow) has more play than 6 mm (1/4’’), then

the tensioner should be adjusted.

1. To do this, loosen the M5 socket screw half a

turn, and rotate the chain adjuster a bit

clockwise (white arrow).

2. Tighten the M5 bolt again whilst holding the

adjuster with the flat-head screwdriver.

3. Check the play of the lower part of the chain

again (black arrow). There should be a play of

roughly 1-2 mm, so the chain must never be

too taut.

Replace the plactic covers.

5-6 Clutch

Necessary tools: open-ended spanner 19mm.

Approximate time: 15 minutes.

Note: to perform the following adjustments, it is necessary to remove the right-hand side cover first.

See section 4-1: Disassembly / Reassembly Plastic Side Covers.

To ensure that the film is not slipping between the pull rollers, yet receiving sufficient tension, the

clutch has to be adjusted properly.

Proceed as follows:

1. Set the machine up for encapsulation using JetGuard 5mil gloss or Thermashield 5mil gloss. Run

the process at 120°C setting, whereas the speed setting should be 2 (which is lower than the

values on the Process Control sticker!). Don’t process any images.

2. While the machine is running, turn the large nut (see figure 36, arrow 3) clockwise, until the friction

discs (arrows 4) are NOT moving in respect of each other. The film, running through the pull

rollers, may create a squeeking noise now.

3. Next, turn the large nut slowly anti-clockwise, just until the discs start moving in respect of each

other again. Continue running the encapsulation process for two minutes to ensure that this

situation is stable.

Replace the plactic covers.

fig. 36

2

3

4