Adjustment Procedures

28

• If the roll pressure is too high, then the footprint looks like:

This is the case if the ends of the footprint (measured 1’’ from either side) are at least 1mm (0.04’’)

wider than the middle.

Change the pressure as described below.

• If the roll pressure is too low, then the footprint looks like:

This is the case if the ends of the footprint (measured 1’’ from either side) are at least 1mm (0.04’’)

smaller than the middle.

Change the pressure as described below.

• If the footprint is narrower (or wider) at one end, and the other

end has the same width as the middle of the footprint, then the

pressure at only that narrower (or wider) end of the machine

should be increased (or decreased).

In general: for either side of the machine counts:

end narrower than the middle

increase pressure at that end

end wider than the middle

decrease pressure at that end

Changing the pressure

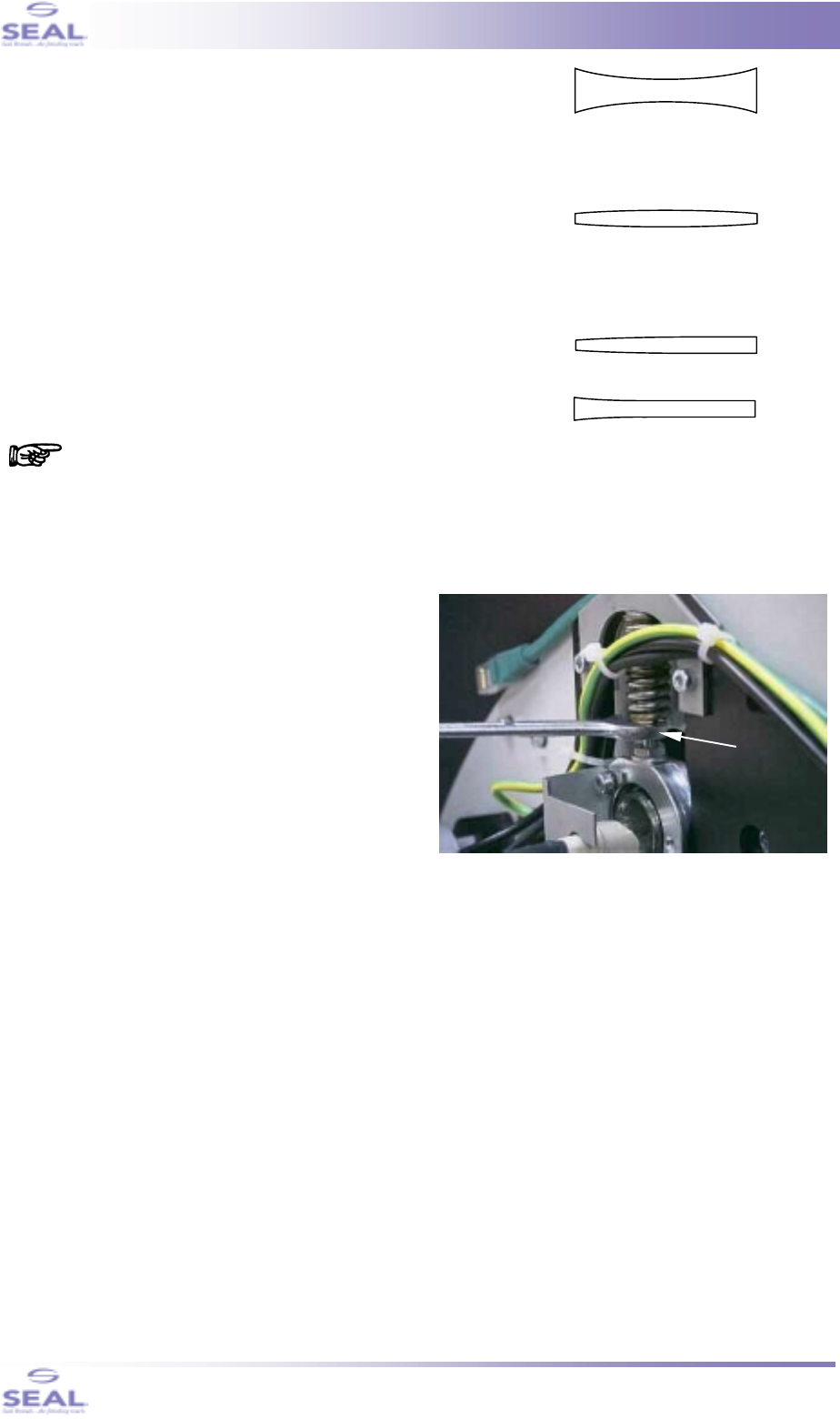

8. To change the pressure, place the 10mm

open-ended spanner on the M6 nut, that is

directly under the compression spring (so, the

upper jamnut, see figure 29, white arrow).

9. Rotate clockwise to decrease the pressure,

counter-clockwise to increase the pressure

(seen from top).

Rotate the jamnut only half a turn on either

side

10. Make a new footprint (go back to step 5)

fig. 29

or