2.1. Trans port

For trans port, only the ap pro pri ate lift ing gear should be used (e.g. fork lift or work shop crane).

»

Ob serve the car ry ing ca pac ity of the lift ing gear.

Ob serve the safety in struc tions for the han dling of lift ing gear.

2.2. Set-up

The ar range ment of the hop per load ers may vary de pend ing on the type of de vice to be con veyed

on and the ma te rial used. Fas ten ing onto fixed ma chine throats is pro vided by means of strap re -

tain ers. How ever, ad di tional sup port of the hop per loader is nec es sary if the de vices are not suf fi -

ciently ca pa ble of bear ing the load.

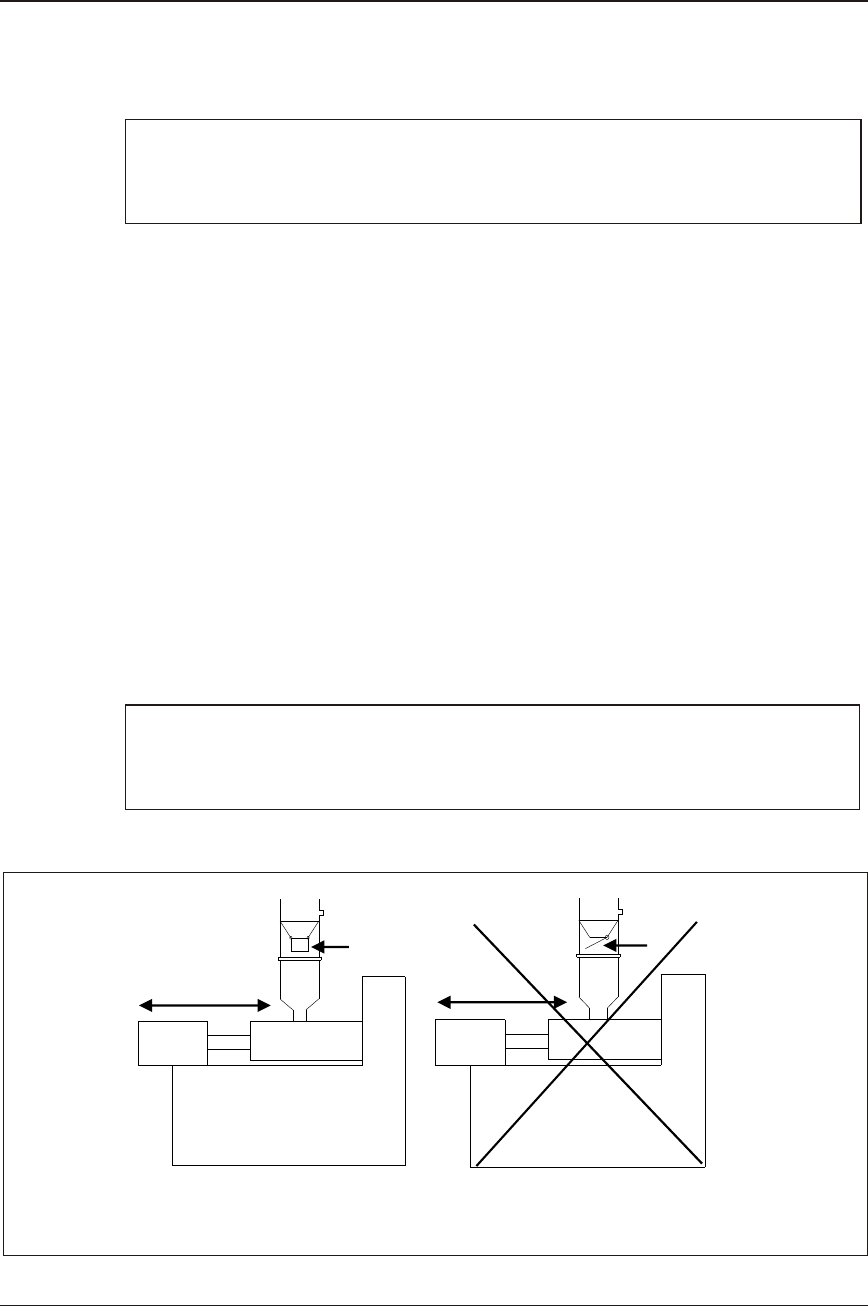

Mount the hop per loader in such a way that the out let flap swings in a right-hand an gle to the di rec -

tion of ma chine move ment. Please check dur ing as sem bly that the ad mis si ble bear ing loads are

not ex ceeded.

Please check that all con nect ing points are tight to en sure that the con vey ing per for mance is not

im paired.

It should more over be ob served, par tic u larly if cus tom pro duced con nect ing parts are used, that

the ma te rial dis charged from the hop per loader must nei ther get into the open nor must it clog the

fil ter sur faces (ob serve an gle of re pose!).

F

Do not ex ces sively load in let noz zle of hop per loader, re move hose sep a -

rately, if nec es sary!

a516-3MS

SSK 5-DURO

In stal la tion in struc tions 10

J

L

Assembly