H

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

Application Note

8

www.tektronix.com/signal_sources

8

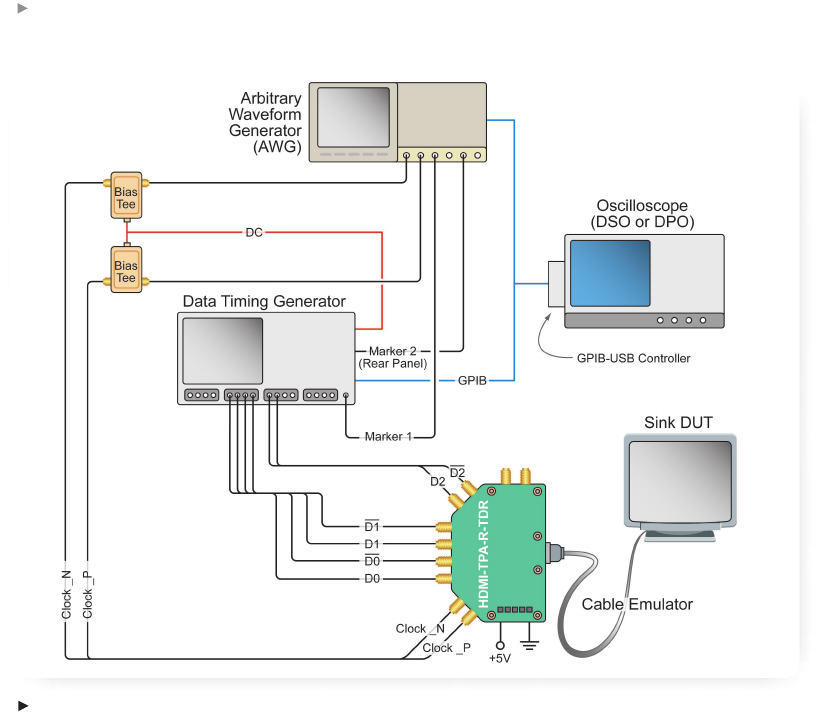

Jitter tolerance tests require a variable amount of jitter

to be imposed on signals being sent to the device

under test. The DTG5000 Series instruments are fully

compatible with either of two recommended jitter

solutions. One solution pairs the DTG5000 Series with

an arbitrary waveform generator for either compliance

or characterization work; the other, lower-cost solution

involves a jitter generator module plugged into the

DTG5000 Series mainframe and driven by an external

function generator. Both approaches provide the

necessar

y modulated jitter pr

ofiles for the generated

clock signal as follows:

–

Arbitrar

y

W

a

vef

orm Generator (AWG) Method:

This solution taps the full power of the DSO and

its TDSHT3 application softwar

e, the DTG5000

Series instr

ument, and the AWG.

The TDSHT3 softwar

e generates the specific jitter

modulation waveform and sends it to the AWG710B,

which in turn acts as the clock source for the jitter

tolerance test. The jitter is steadily increased by the

softwar

e until the device fails. The data lines ar

e

then verified by the oscilloscope for compliance.

The A

WG has two digital “Marker” outputs that can

be used for synchronization, among other purposes.

In HDMI sink testing, one marker connects to the

DTG5000 Series exter

nal clock input while the second

marker connects to the DTG5000 Series trigger

input, both providing synchronization. Data signals

for the device under test are sourced by the

DTG5000 Series. Bias Tees are required to bring the

AWG710B out put's clock signals up to the required

TMDS levels. Conveniently

, these Bias T

ees can be

powered by the built-in DC output on the DTG5000

Series. The A

WG method is able to str

ess the

device beyond the compliance specification levels,

making it suitable for characterization work. Figure 5

illustrates the layout of a test configuration using the

A

WG method.

Figure 5.

Sink jitter tolerance test setup using an AWG as the jitter source.