E6581371c

- 9 -

3.2. VF-FS1 communication parameters

Set up the inverter parameters as follows. To update, reset the power of inverter. If these

parameters are not set to correct value, this unit can not work normally.

Title Function Description

cmod Command mode selection

fmod Setpoint mode selection

While L

ONWORKS communication option is installed

into VF-FS1, The network command and setpoint are

prior to cmod/fmod. VF-FS1 front panel operation

is prior when LOC lamp on the front panel turns on.

f800 Communication speed Set “1: 19200bps” (default).

f801 Parity Set “1: Even” (default).

f803 Communication error trip time Set communication time out period.

f829 Communication protocol Set “1: MODBUS-RTU”

f851 Operation at network error

Set the behavior when “Receive heart beat timer”

overflow occurred.

Warning

Mandatory

Set up “Communication error trip function (f803, see the inverter instruction

manual for details)” to stop the inverter when this option unit is deactivated by an

unusual event such as tripping, an operating error, power outage, failure, etc.

Deactivated option unit may cause an accident, if the “Communication error trip

function” is not properly set up.

3.3. Network cable connection

Connect the LONWORKS

network cable to LONWORKS communication option as follows.

(1) Cable selection (a twisted pair cable with shield)

Use Level 4/22 AWG cable for the network cable.

- Recommended cable

Manufacturer: Showa Electric Wire & Cable Co., Ltd.

Model name: LW221S, 22AWG, 1P, With shield, Standard 300m/reel

Use 0.75mm

2

wire for grounding to the earth terminal (G/E) of the board.

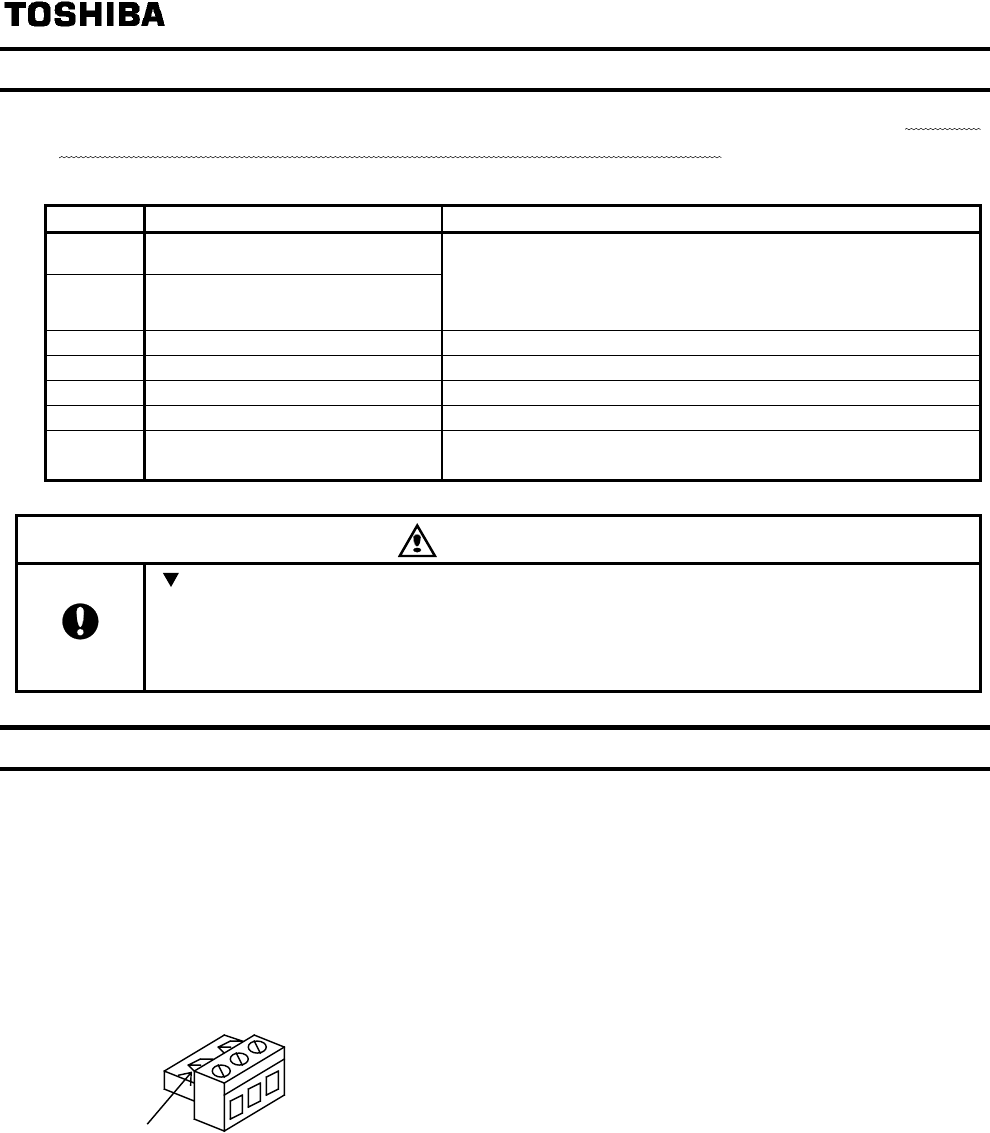

(2) Terminal blocks

NET

A

SHLD

NETB

Catches

Manufacturer: PHOENIX CONTACT

Model name: MSTB 2,5/3-ST-5.08

- Communication terminal NETA, NETB

Connect L

ONWORKS

transmission/reception data cable.

Polarity of the communication terminals NETA and NETB does not have to be considered.

- Communication shield terminal SHLD

Connect the shield of network cable. Refer to next section for grounding.

- G/E terminal

Connect the network ground.

(3) Connection

Cable sheath should be peeled off by about 7mm.

For wiring work, use a flat blade screwdriver with a 0.6mm thick and 3.5mm width blade.

Tightening torque for the terminal block is 0.5Nm.