36

36

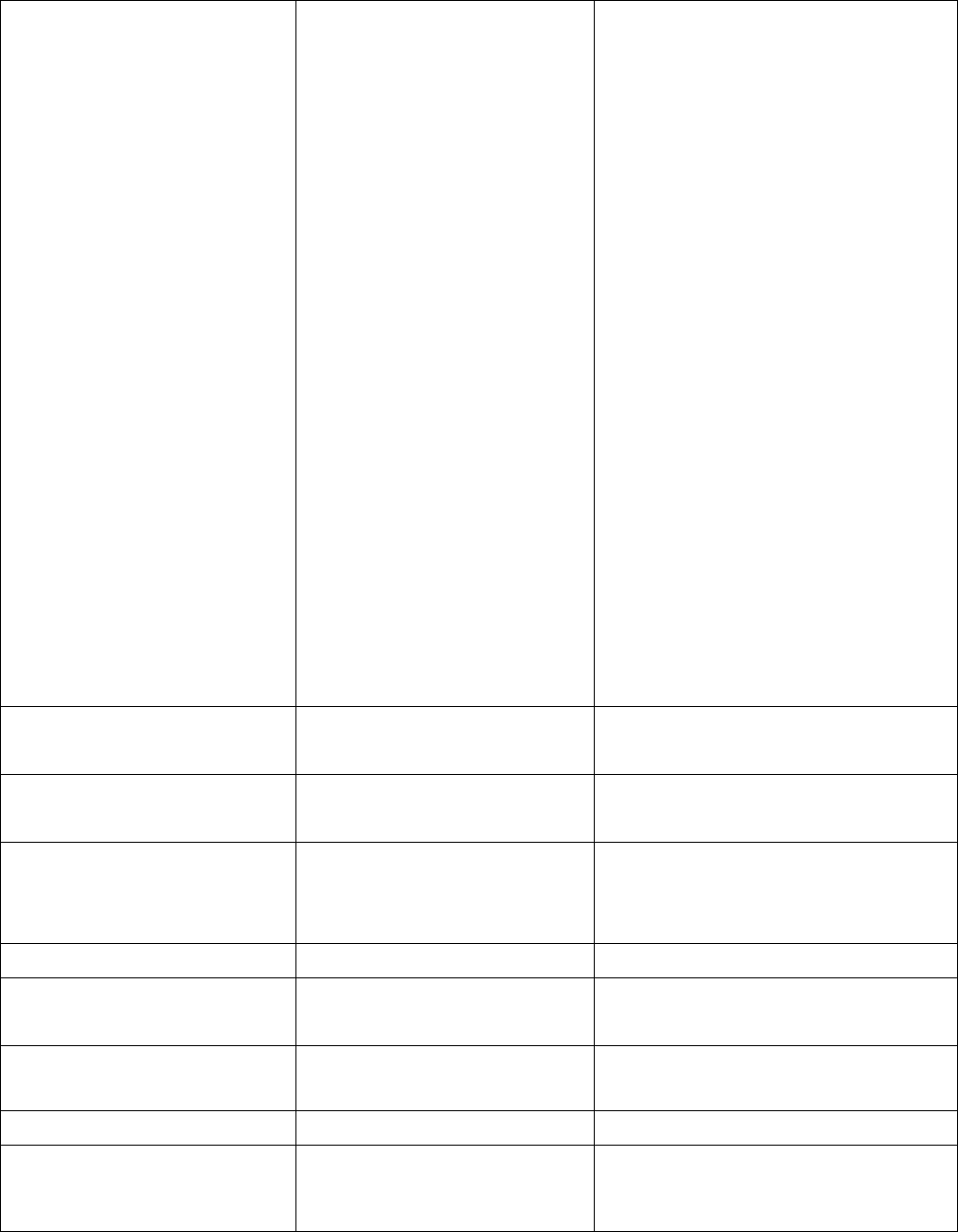

Poor Print Quality

* Ribbon and media is loaded

incorrectly

* Dust or adhesive accumulation on

the print head.

* Print density is not set properly.

* Print head element is damaged.

* Ribbon and media are

incompatible.

* The print head pressure is not set

properly.

* Reload the supply.

* Clean the print head.

* Clean the platen roller.

* Adjust the print density and print speed.

* Run printer self-test and check the print

head test pattern if there is dot missing in

the pattern.

* Change proper ribbon or proper label

media.

* Adjust the print head pressure adjustment

knob.

- If the left side printout is too light, please

adjust the left side pressure adjustment

knob to the higher index (higher

pressure). If the pressure adjustment

knob has been adjust to index “5” and

the poor print quality is still at the left

side of the printout, please adjust the

pressure adjustment knob to index “1”

and use the Z-axis adjustment knob to

fine tune the pressure.

- If the right side printout is too light,

please adjust the right side pressure

adjustment knob to the higher index

(higher pressure) to improve the print

quality.

* If the label thickness is more than 0.22

mm, the print quality might be not good

enough, please adjust the heater line

adjustment screw counter clockwise to

get the best print quality.

* The release lever does not latch the print

head properly.

LCD panel is dark and keys are

not working

* The cable between main PCB and

LCD panel is loose.

* Check if the cable between main PCB and

LCD is secured or not.

LCD panel is dark but the LEDs

are light

* The printer initialization is

unsuccessful.

* Turn OFF and ON the printer again.

* Initialize the printer.

LCD panel is dark and LEDs are

lit on, but the label is feeding

forward

* The LCD panel harness connector

is loose.

* The LCD panel harness connector is

plugged upside down.

Peel sensor is not working

* The connector is loose.

* Plug the connect cable correctly.

Ribbon encoder sensor doesn’t

work

* The ribbon encoder sensor

connector is loose.

* Fasten the connector.

Ribbon end sensor doesn’t work

* The connector is loose.

* The ribbon sensor hole is covered

with dust.

* Check the connector.

* Clear the dust in the sensor hole by the

blower.

Cutter is not working

* The connector is loose.

* Plug in the connect cable correctly.

Label feeding is not stable

(skew) when printing

* The media guide does not touch

the edge of the media.

* If the label is moving to the right side,

please move the label guide to left.

* If the label is moving to the left side,

please move the label guide to right.