Operators Manual

ALS 230

Release 11/05 Page 13 Description

Dispensing is only possible when the handle (015) is in the closed position. Via the deviator

roller (016) the backing paper is guided to the rewind mandrel (017). The cone between the 4

pins can be pulled out to allow the reward backing paper to be removed.

Except for the drive roller (001) and the material brush (006) the labeller has no wearing parts.

The operator panel (019) is described in the next chapter.

A threading diagram is affixed to the front of the machine, which shows how the label material

should be threaded through the machine.

Screw (014) secures the position of the pressure roller (013) in a lateral direction. In order to

achieve a reliable run of the label web position, adjust the roller to the centre of the label web.

2.2 Operator panel

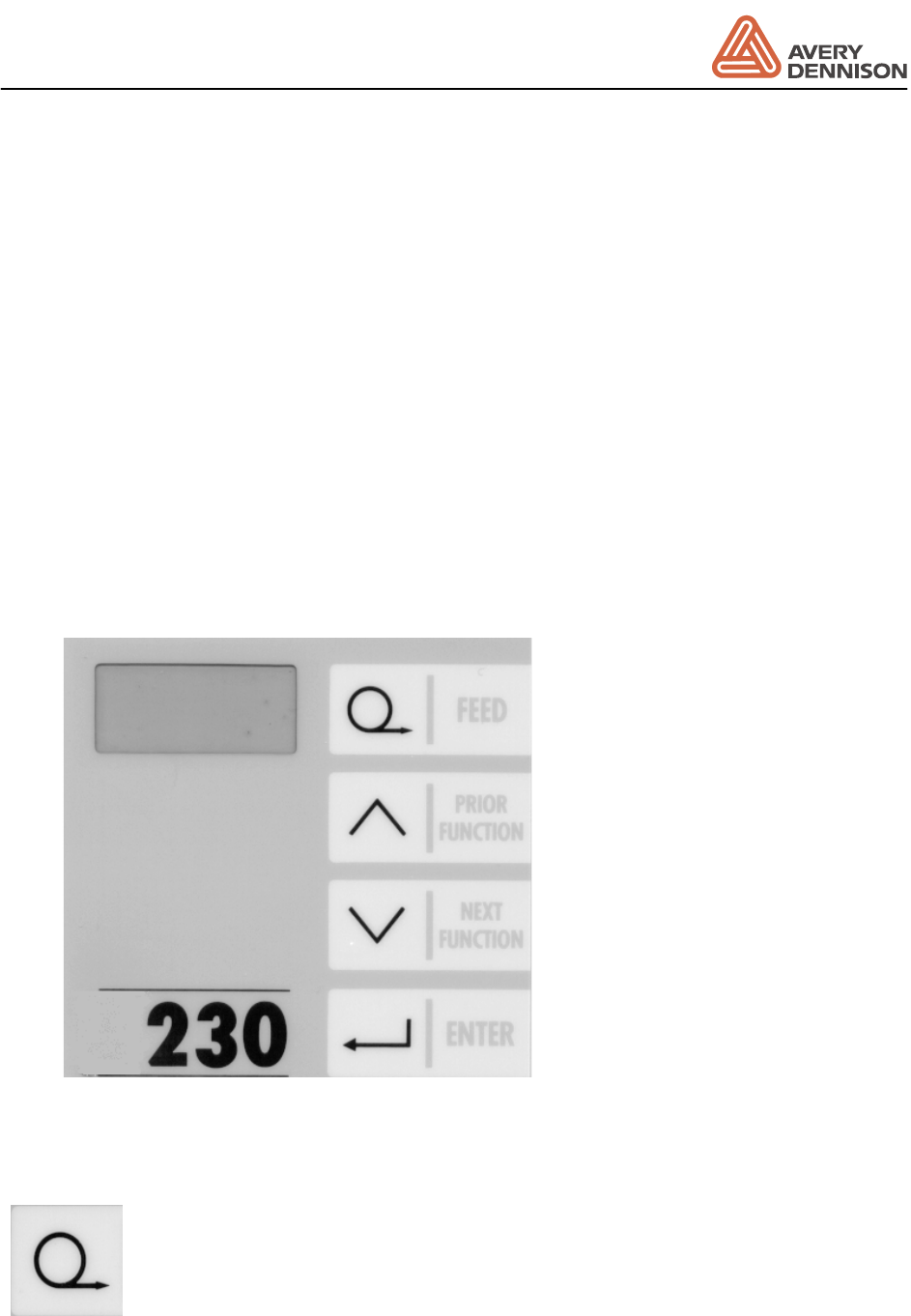

The operator panel (Figure 2) of the 230 is shown below, it has a 4 digit LED display and 4

membrane keys.

Figure 2 Operator panel

The 4 membrane keys have following functions:

FEED: By pressing this key one label will be dispensed. When the machine

displays INIT pressing this key will start initialisation of the machine. An

initialisation has to be made each time a new material is used. If the FEED key is

pressed and held as the machine is turned on then the machine carries out an

automatic initialisation of the label parameters "CONT" and "LPIT".