724-746-5500 | blackbox.com

Page 20

724-746-5500 | blackbox.com

Chapter 2: Installation

When determining the installation location, consider how you’ll route the piping and wiring into the cabinet and ensure access is

available (see Sections 2.7.1 and 2.8.1). The Cold Row system is ordered from the factory with pilot holes for piping and wiring in

either the top or the bottom of the cabinet. See the installation drawing provided with your unit for the pilot hole locations.

Conditioned Space

Take certain steps to minimize the effects of the environment surrounding the conditioned space. This is especially important for

critical/precision room preparation (computer data centers) that require close tolerance control of temperature and humidity. The

conditioned space should be well insulated and include a vapor barrier. The installer should ensure that the proper insulation

rating is used based on the design of the space, which was the basis for the system selected. The following table lists

recommended minimum R-value (thermal resistance values) for optimum equipment operation.

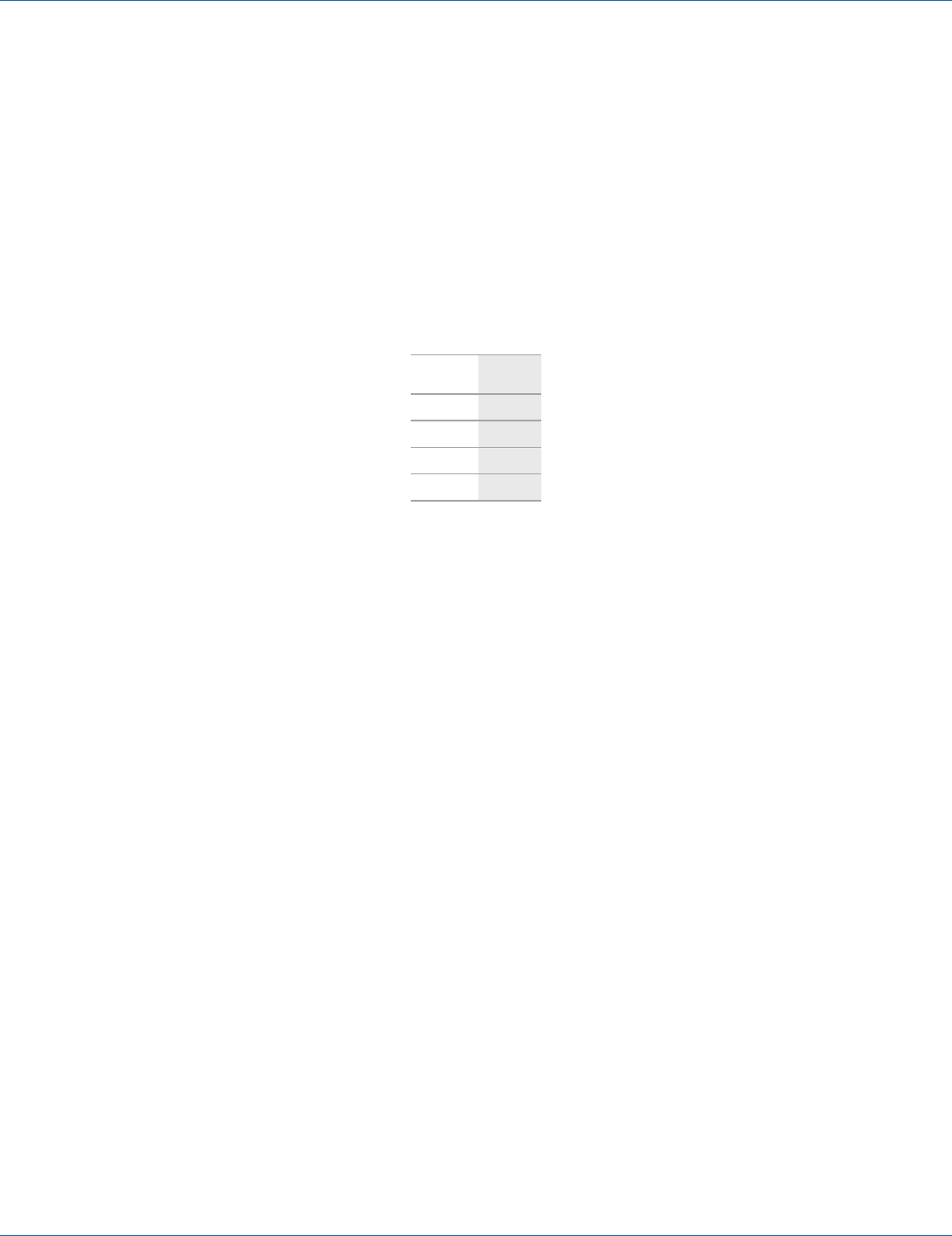

Table 2-1. Recommended

minimum thermal resistance.

Structure R-Value

Ceiling R-38

Wall R-21

Floor R-19

Door R-5

The vapor barrier is the single most important requirement for maintaining environmental control in the conditioned space. The

vapor barrier in the ceiling and walls can be a polyethylene film. Concrete walls and floors should be painted with a rubber- or

plastic-based paint. Doors and windows should be properly sealed, and a door sweep used to minimize leakage. Outside or fresh

air should be kept to a minimum (as it adds to the cooling load), while maintaining the requirement of the Indoor Air Quality

(IAQ) standard. Lack of these steps can cause erratic operation, unstable room control, and excessive maintenance costs.

2.4 Mounting/Placement

The Cold Row precision A/C system uses a frame and panel construction for unit rigidity and full-service access while the unit is

mounted in place.

NOTE: The equipment must be level to operate properly.

Cold Row cabinets are designed to be installed in a row of servers between the server racks (see Figures 2-1–2-3). They have a

compact footprint that allows the units to be placed adjacent to the heat-producing equipment racks anywhere in the row. They

provide cool, conditioned air through the front grille to the adjacent server modules on the cold aisle side of the row. We

recommend positioning the unit to obtain optimum air circulation. Allow 36" clearance in the front and rear of the cabinet for

servicing the unit.

The optimal placement location is next to highly loaded servers that throw off the most significant heat into the hot aisle side of

the row. In this arrangement, the Cold Row minimizes hot spots. It is best not to place a Cold Row unit at the end of a row unless

an air barrier is in place to prevent the conditioned air from being drawn around to the hot aisle side, bypassing the front of the

servers. An air barrier must also be present to prevent conditioned air from being drawn over the top of the row into the hot

aisle.