Cam No. 3 (28 and 28A) monitors the effective-

ness of the press braking system at the top of

the stroke. When cam No. 3 is positioned

according to Paragraph 2.3, deviations in

stopping position greater than

+

15” from top

dead center will be detected.

2.0 Installation

n

!

Danger:

Prior to installation of the

Airflex’“’

Timing

Rotorseal and Cam Limit Switch, make sure

that the machinery is secured in a safe

manner. Failure to do so could result in

serious injury or possibly death.

n

!

Warning:

Only qualified maintenance personnel should

install, adjust or repair these devices. Faulty

workmanship will result in unreasonable

exposure to hazardous conditions, injury or

severe damage to the equipment.

n

!

Caution:

Before you begin any work, study this manual

so that you completely understand what is

required. Do not risk injury. Follow the

instructions.

2.1

Mounting

Instructions for mounting the

Airflex’)

timing

rotorseal, foot and shaft mounted cam limit

switches are given below. Any combination of

these times may be used in the control

system. Follow those instructions that pertain

to the timers being used.

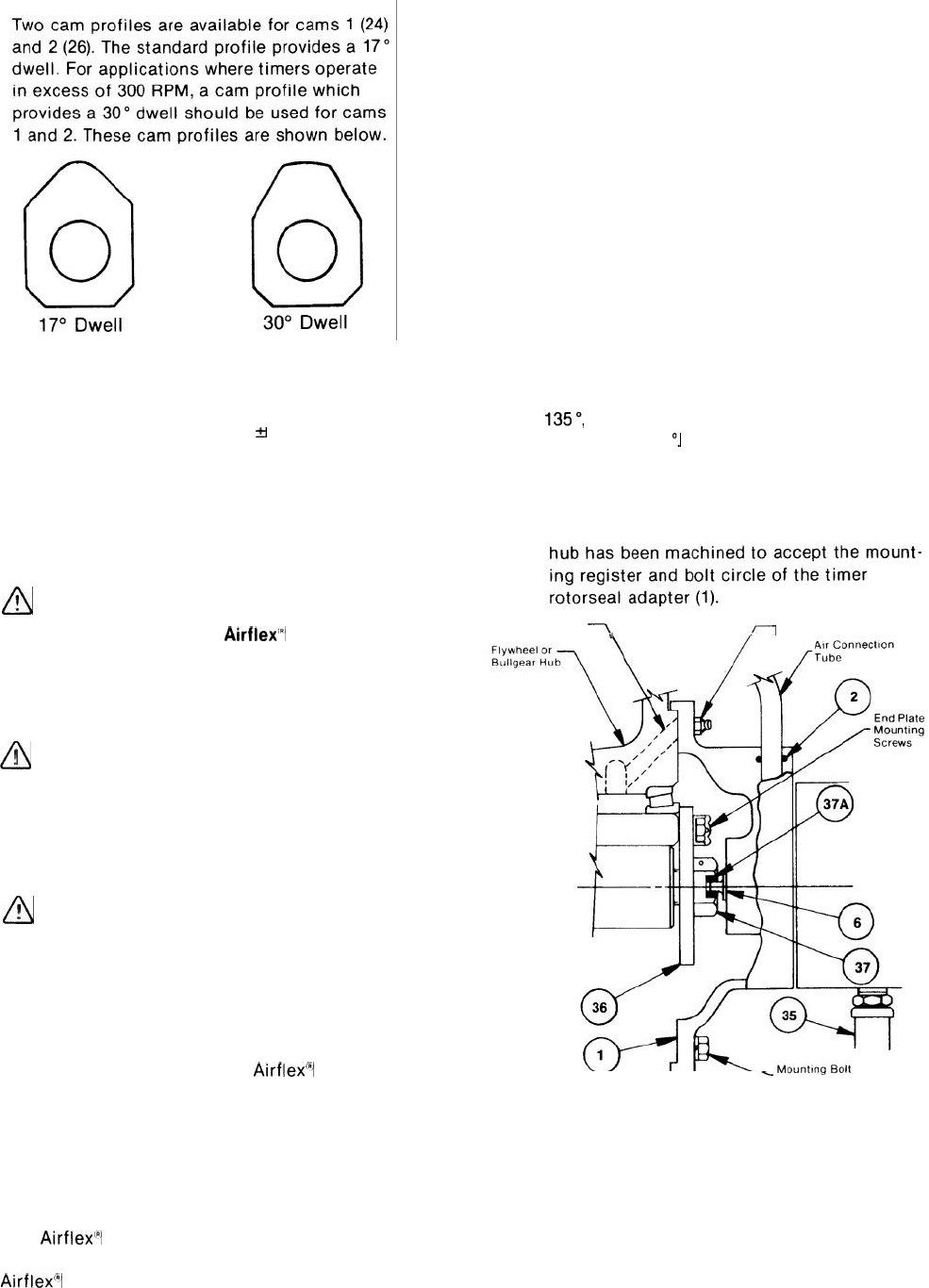

2.1 .1 Timing Rotorseal:

The

Airflex@

timing rotorseal is custom

designed to fit the flywheel or bullgear of an

Airflex@

FSPA clutch and brake package as

shown in Figure 2. The flywheel or bullgear

All control systems, except those capable of

inch and continuous functions only, require

two timers. When two timers are used, except

on control panels with semicontinuous func-

tion, only the two piece cam No. 3 of the “A”

timer is required for brake monitoring. The

cam No. 3 of the “B” timer, is available for a

user’s special function such as a counter. The

optional one piece cam No. 3 profile is the

same as cam No. 4 shown in Figure 1.

LS4 is controlled by split cams 4 (33) and 5

(33A). This set of cams determines the top

stop setting and the amount of time the run

buttons must be depressed before the operator

can remove his hands from them. If the run

buttons are released before this predetermin-

ed setting, the press will stop.

The minimum dwell setting of these cams is

135”,

and they are fannable up to 255” in in-

crements of 40

‘.

For the proper setting of

these cams, refer to Paragraph 2.3.

Grease Hole

\

\

/-

Grease Fitting

Figure

2. Timing rotorseal mounting configuration

and Lockwasher

The timing rotorseal end plate (36) is used to

assemble the device to the crankshaft. The end

plate also provides the necessary bearing run-

ning clearance and must be properly shimmed.

Follow instructions given in Form PP3000.

Before mounting the timing rotorseal, check

to be sure its direction of rotation corresponds

with that of the flywheel or bullgear.

4