2.1.2.

To

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

mount the timing rotorseal:

Make sure that the air tube “O” rings (2)

are in place.

Install the plastic insert (37A) in the head

of the drive screw (37).

Install drive screw. Tighten the screw, being

careful not to distort the end plate (36).

Tie-wire the drive screw to the end plate

mounting screws.

Align the tang of shaft (6) with the slot in

the drive screw insert, and align the

grease holes in the adapter (1) with those

in the hub of the flywheel or bullgear.

Install the lockwashers and mounting

bolts. Tighten the mounting bolts uniform-

ly SO the adapter flange fits squarely

against the register face.

Inspect all air connection tubes and

remove all burrs.

Lightly grease or oil the ends of the air

tubes and insert them into the mating

adapter holes.

Attach the opposite ends of the tubes to

their connections.

Connect flexible air hose (35) to the

center section and air supply line.

A

!

Caution:

Do not use a rigid pipe air line in place of the

flexible air hose (35). Rigid pipe does not

allow compensation for any eccentricity be-

tween the device and the shaft and will cause

a preload condition that will shorten the bear-

ing life of the device.

k)

Apply air pressure and check for air leaks.

Repair as required.

l)

Remove air pressure.

m)

Refer to appropriate paragraph and mount

second timer.

Wiring instructions are given in Paragraph 2.2.

Foot Mounted Cam Limit Switch:

The foot mounted cam limit switch must be

chain driven by the crankshaft. The sprocket

ratio between the shaft and switch must be

1:1. Sprockets furnished by

Airflex”

are 3/8

in. pitch. Chain of proper length, determined

by the placement of the timer, and the chain

guard must be furnished by customer.

Mount the timer as follows:

a)

Select a convenient mounting area for the

timer so that there is no interference with

the chain drive. Locate the timer as close

as possible to the driving shaft so that

the chain length is held to a minimum.

b)

c)

d)

e)

f)

g)

h)

Rigidly attach a sprocket to the drivi

/i

g

shaft.

Key the other sprocket to the cam limit

switch shaft and lock it in position with

set screws and jam screws. The cam limit

switch shaft diameter is .6250/.6245

inches, has a 3/16 inch square keyway

and has a one inch long mounting length.

Fabricate a sturdy bracket or prepare the

machine surface for mounting. Bear in

mind that the bracket design or positioning

of the switch will be influenced by the

direction of rotation of the switch.

Position the switch so that the driving

and driven sprockets are in alignment.

Fasten the switch to its support with four

3/8 inch cap screws and lockwashers.

Attach and tension the drive chain

following chain manufacturer’s

recommendations.

Fabricate a guard to cover sprockets and

chain.

Refer to appropriate paragraph and mount

second timer.

Wiring instructions are given in Paragraph 2.2.

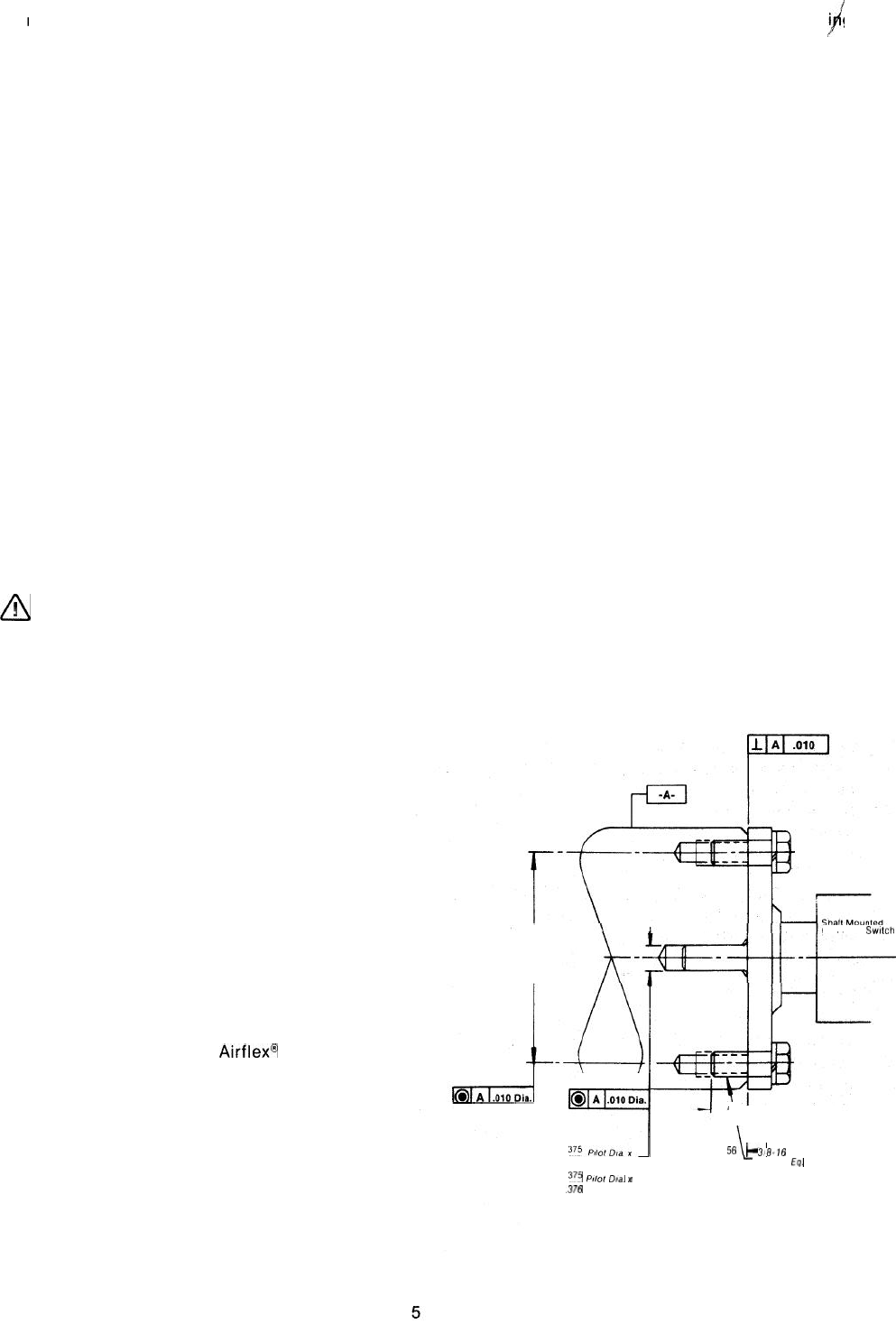

2.1.3 Shaft Mounted Cam Limit Switch:

The shaft mounted cam limit switch is design-

ed for attaching directly to a shaft end. The

shaft end must be machined as shown in

Figure 3 to accept the shaft pilot and bolt

circle.

3. 250

Dia B. C.

Cam Limit

Swtch

@ A

.OlO

Dia.

“i

3’5

PI/Of

Da.

Y

,376

1.25 Deep

56

I-

318-16

NC-2

4 Bolts

Eq.

Spaced

Figure 3. Shaft machining details