Breaker Point Opening Gap:

This gap is preset at the factory on new units

at time of assembly. A gap setting of .040” to

.050” must be maintained at all times. The

opening gap must be checked regularly and

reset when required. To inspect for proper

opening gap:

a)

b)

c)

d)

e)

h)

i)

j)

k)

Position the crankshaft at top dead center.

Use die safety blocks or otherwise secure

to hold the ram in this position.

Turn electrical power

off

to main control

panel.

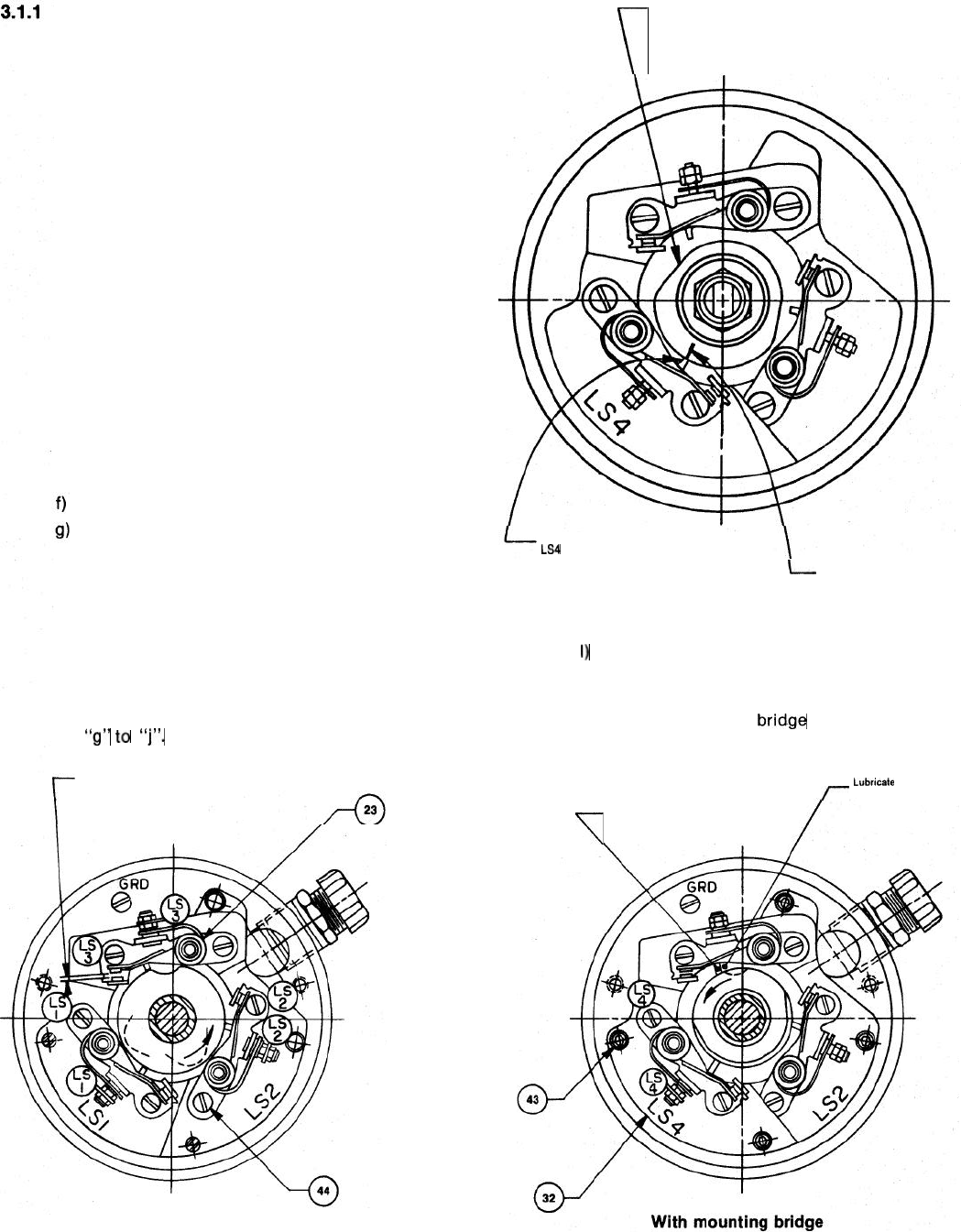

Remove end cap (31) from timer by remov-

ing the two socket head cap screws.

Mark the location of the fiber follower of

the LS4 (42) breaker point with respect to

the cam No. 5 (33A). This will prevent the

need for several timer adjustments to

locate the top stop position. See Figure 5.

To inspect LS1, refer to Figure 6 and

remove the two socket head cap screws

(43) and mounting bridge sub-assembly (32).

Loosen jam nuts (30).

Rotate cam adjusting knob (29) so that

breaker point gap being measured is at

its maximum opening.

Measure gap as indicated in Figure 6.

If gap must be adjusted, follow instruc-

tions given in Paragraph 3.1.2.

Lubricate the cam follower with a multi-

purpose lithium soap grease.

Measure gap of LS2 by repeating Steps

“g”

to

“j”.

Opening Gap

Adjust To .040 - .050 inches

Mounting bridge removed

T

Cam No. 5 (33A)

Fiber Follower

LS4

\

Mark As Shown

Figure 5

Marking top stop position

1)

Rotate No. 3 cam (28A) so that breaker

point gap of LS3 is at its maximum opening.

m) Repeat Steps “h” through “j”.

n) Replace mounting

brid.ge

sub-assembly

(32) and cap screws (43).

Lubricate

r

Here

\

Fiber Cam Follower

Figure 6

Breaker point maintenance

8