C141-E035-02EN 4 - 13

(4) Sequential starting of spindle motors

After power is turned on to the IDD, a large amount of current flows in the +12 VDC line

when the spindle motor rotation starts. Therefore, if more than one IDD is used, the spindle

motors should be started sequentially using one of the following procedures to prevent

overload of the power supply unit. For how to set a spindle motor start control mode, see

Subsection 5.3.2.

a) Issue START/STOP commands at 20-second intervals to start the spindle motors. For

details of this command specification, refer to SCSI Logical Interface Specifications.

b) Turn on the +12 VDC power in the power supply unit at 20-second intervals to start the

spindle motors sequentially.

(5) Power supply to SCSI terminating resistor

If power for the terminating resistor is supplied from the IDD to other SCSI devices through

the SCSI bus, the current-carrying capacity of the +5 VDC power supply line to the IDD must

be designed with considering of an increase of up to 200 mA.

A method of power supply to the terminating resistor is selected with a setting terminal on the

IDD. See Subsection 5.3.2 for this selection.

For the electrical condition of supplying power to the terminating resistor, refer to Subsection

1.4.2 in SCSI Physical Interface Specifications.

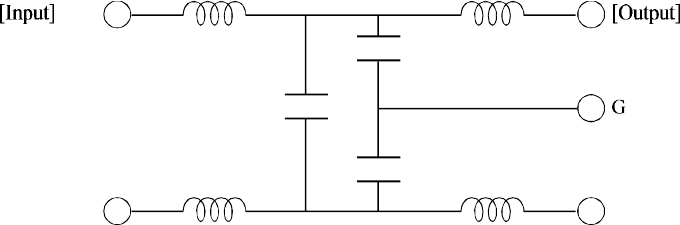

(6) Noise filter

To eliminate AC line noise, a noise filter should be installed at the AC input terminal on the

IDD power supply unit. The specification of this noise filter is as follows:

• Attenuation: 40 dB or more at 10 MHz

• Circuit construction: T-configuration as shown in Figure 4.15 is recommended.

Figure 4.15 AC noise filter (recommended)