NJ750 Training Guide

4

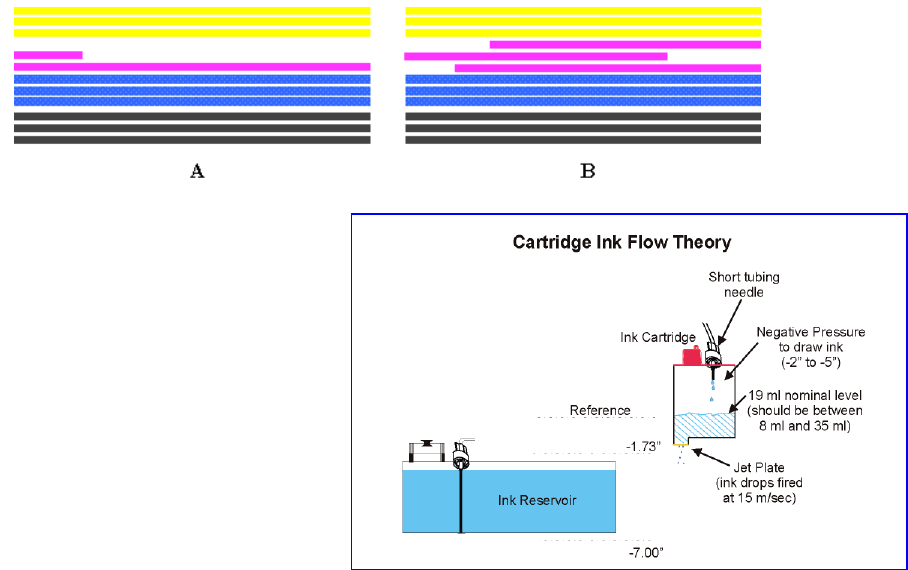

down a solid band of color with 33% ink load.

Color Test Failures:

- Example A above depicts

complete ink starvation in magenta.

This problem may be corrected by

using the EasyPrime and

establishing the required pressure

inside the cartridge. Replace

septum connector/needle if repeated

attempts continue to fail.

- Example B above depicts partial

ink starvation in magenta (ink fires

at 100% at the beginning of each

pass but then starves). This

problem can be corrected by

ensuring 19 ml of ink is present

inside the cartridge (level must be between 8 ml and 35 ml for proper operation – refer to

NOTE below).

NOTE: To install ink into a cartridge or to verify proper cartridge ink level obtain syringe

with tube extension from accessory kit. Pull 20 ml of ink into syringe. Lift cartridge stall

position valve to up position to cut off ink flow. Temporarily remove septum connector

from cartridge. Install ink into cartridge by depressing syringe plunger; pull back on

plunger to remove excess ink (if any). Reconnect septum needle to cartridge and close

valve actuator (lower) to restore ink flow to cartridge. The cartridge will need to be primed

to restore negative pressure inside cartridge – refer to step 3 above.

5. Activate the Prime pattern.

Select UTILITY MENU – PRIME. Verify all colors are printed. Verify no clogs are

present in the prime pattern. Manual or automatic jet compensation is provided up

to 20 jets in each cartridge. Ensure the integrity of the diagonal lines are

consistent and smooth. Clean or replace cartridge if unsatisfactory.