A-61500 April 2007 6-13

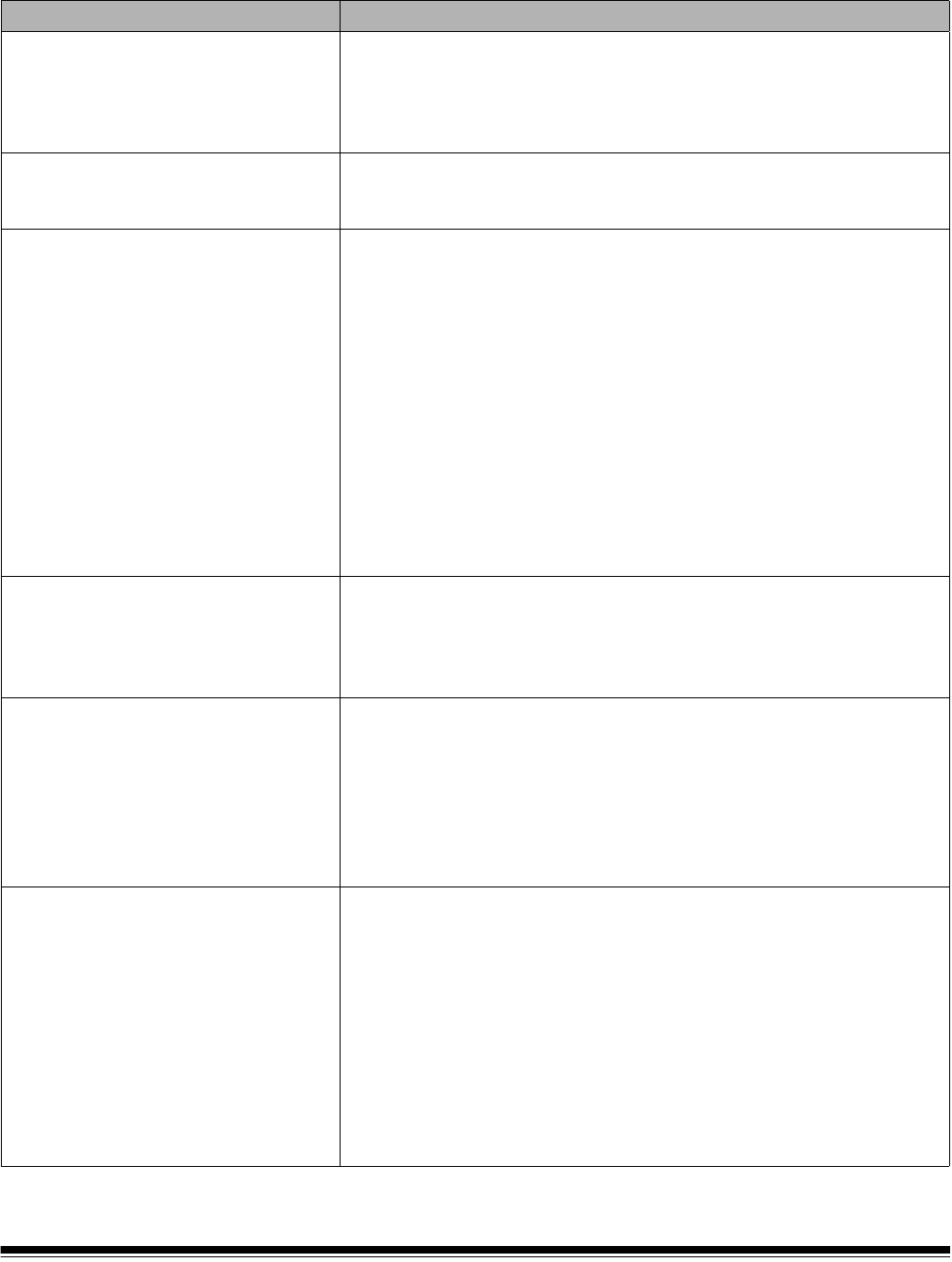

Problem solving Use the chart below as a guide to check possible solutions to problems

you may encounter when using the Kodak i600 Series Scanner.

Problem Possible Solution

Scanner does not power on Make sure that:

• the power cord is plugged securely into the receptacle in the back of

the scanner.

• the wall outlet is not defective (call a licensed electrician).

• the power switch is on.

Scanner is not being recognized by the

Scan Validation Tool

Make sure that:

• when the software was installed, it was installed by someone with

Administrator privileges.

The scanner will not scan/feed

documents

Make sure that:

• the power cord is plugged in and the power is on.

• all doors are completely closed.

• the scanner is enabled from the host.

• documents are making contact with the feed module.

• for documents that require special handling, press the gap release

lever during feeding.

• the documents meet specifications for size, weight, etc.

• if you are feeding small documents, be sure that the documents are

covering the paper present sensor on the elevator tray.

• you check the feed module, separation roller, and pre-separation pad

for signs of wear and replace these parts if necessary.

• a very dark document on the bottom of a stack, or curled document

lead edges, can sometimes confuse the paper present sensor. Place a

white sheet of paper at the bottom of the stack and scan again.

Image quality is poor or has decreased Make sure that:

• the imaging guides are clean. See Chapter 5, Maintenance.

• the scanner has been calibrated. See Chapter 3, “Calibrating the

scanner”.

If unsatisfactory image quality persists, call Service.

Calibration has failed Make sure that:

• you are using the proper calibration target and it is oriented correctly for

the type of calibration you are performing. The Image calibration target

and Ultrasonics calibration target are different.

• the imaging guides are clean.

• the transport is clear of obstructions.

• the sensors are clean.

If unsatisfactory image quality persists, call Service.

Documents are jamming Make sure that:

• the output tray and side guides are adjusted for the length of the

documents being scanned.

• all jammed documents have been removed from the transport area.

• documents meet specifications for size, weight, height or batched

documents, etc.

• the sensors are clean.

• the separation roller, feed module, and pre-separation pad are clean

and properly installed.

• the transport rollers are clean.

• you check feed roller, separation roller and pre-separation pad for

signs of wear and replace as needed.