DEVELOPING UNIT CF5001 Ver.1.0 Sep. 2003

2-26

II UNIT EXPLANATION

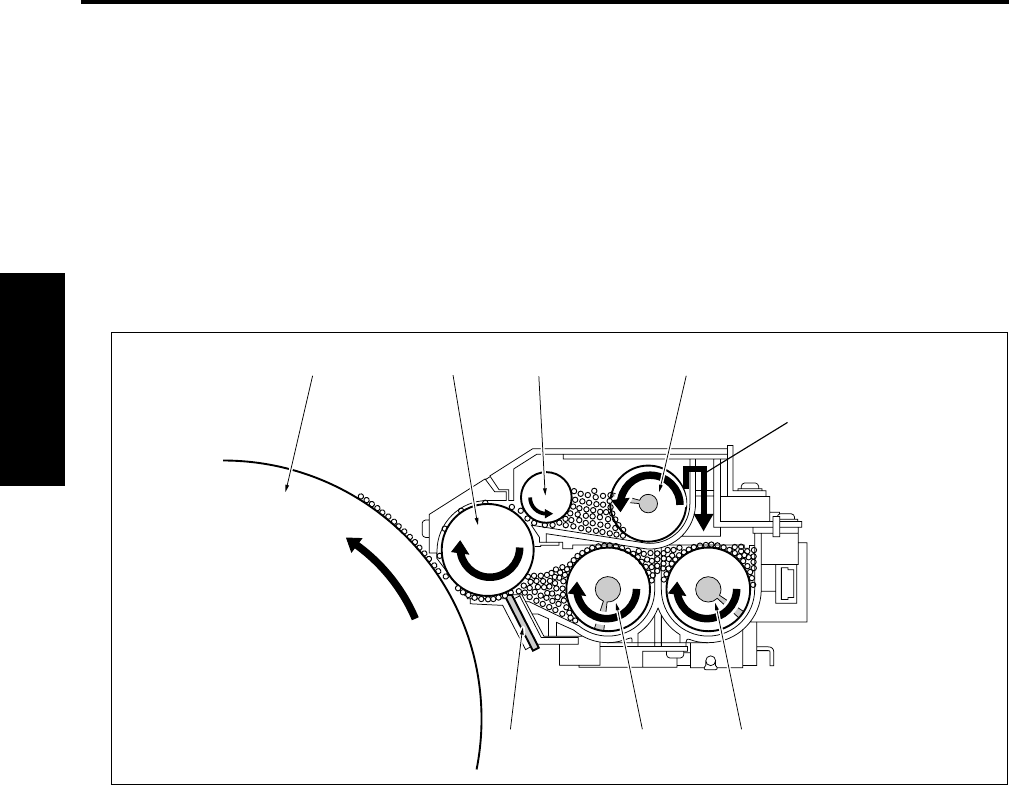

4.2 Operation

4.2.1 Flow of developer

Developer in the developing unit, after being agitated by the agitator screw, is supplied to the developing

sleeve by the conveyance screw. At this time, the bristles amount of the developer on the developing

sleeve is regulated by the developing regulation plate. After completion of developing, the developer on the

developing sleeve is collected by the scraper magnet roller to prevent the developer immediately after com-

pletion of developing from mixing with a new developer. This secures the developing follow-up at a high

rate of printing. Collected developer is returned to the agitator screw by the collection screw. This allows

developer to make a circulation along a defined path.

4.2.2 Developing control

For details of each operation timing related to developing, see "Image formation timing" in "3. Drum unit."

4.2.3 Toner supply control to the developing unit

Each of the TDS Y, M, C and K (toner density sensors /Y, /M, /C and /K) uses the L detection method (per-

meability detection of the developer) to detect the toner density of the developer. A value thus obtained is

compared with the reference value of the toner density stored in the CPU on the printer control board

(PRCB) to check to see if the toner needs to be supplied. (For toner supply operation, see "6. Toner sup-

ply.")

[1] Agitator screw [5] Developing sleeve

[2] Conveyance screw [6] Scraper magnet roller

[3] Developing regulation plate [7] Collection screw

[4] Drum

8050ma2014

[1][2][3]

[4] [5] [6] [7]

Toner