Split System Models

53

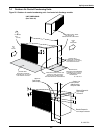

7.6 Water and Glycol-Cooled Condensing Units

For installation guidelines, refer to Installing the Indoor Condensing Unit on page 48.

7.6.1 Piping Considerations

It is recommended that manual service shut-off valves be installed at the supply and return line to

each unit. This will provide for routine service or emergency isolation of the unit.

When the water source for the condenser is of poor quality, it is good practice to provide cleanable fil-

ters in the supply line. These filters will trap the particles in the water supply and extend the service

life of the water-cooled condenser.

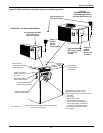

7.6.2 Condenser Water Requirements

The standard maximum water pressure is 150 psig (1034 kPa). For applications above this pressure,

consult the factory about high pressure systems.

The system will operate in conjunction with a cooling tower, city water, or drycooler.

7.6.3 Regulating Valve Adjustment and Testing

Refer to 4.3.1 - Water Regulating Valve Adjustment and 4.3.3 - Testing Valve Function.

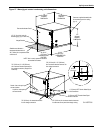

7.6.4 Glycol Systems

For split system glycol systems, use drycooler and pump data found in 5.0 - Glycol/GLYCOOL-

Cooled Models. See Table 16 - Drycooler data.

Electrical control interconnect to drycooler is wired from water/glycol condensing unit.

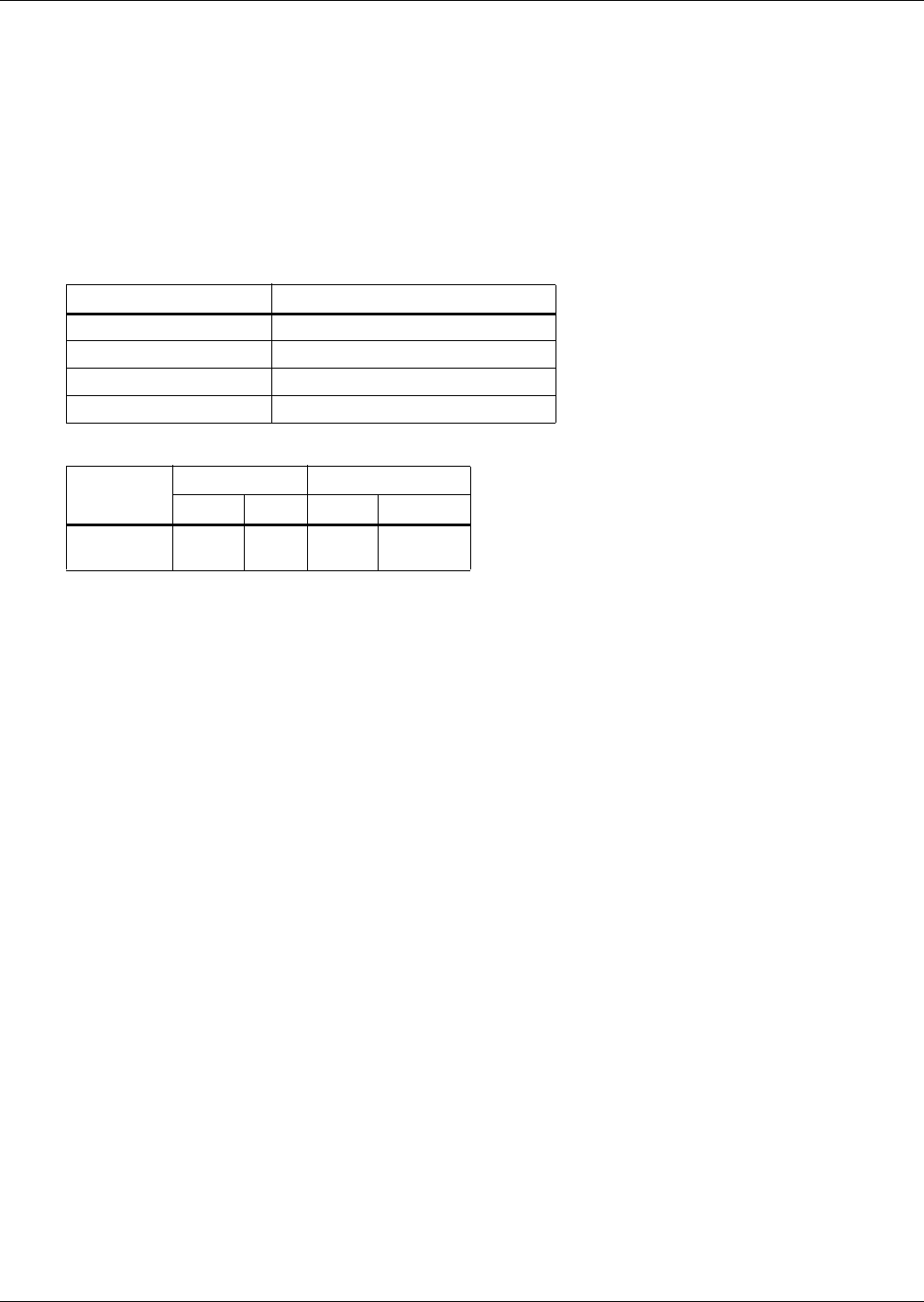

Table 30 Water and glycol-cooled unit connection sizes

Connection Size and Type

Condenser Water Inlet 1-1/8" OD Cu

Condenser Water Outlet 1-1/8" OD Cu

Suction Line 1-7/16" - 16 male #12 quick connect

Liquid Line 1-1/16" - 12 male #10 quick connect

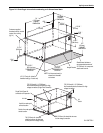

Table 31 Water and glycol-cooled condensing unit data

Model

Net Weight Glycol Volume

lb kg gal liters

MC_69W

MC_68W

282 128 2.0 7.6