Design Considerations (Continued)

Designs using the HPC family of 16-bit high speed CMOS

microcontrollers need to follow some general guidelines on

usage and board layout

Floating inputs are a frequently overlooked problem CMOS

inputs have extremely high impedance and if left open can

float to any voltage You should thus tie unused inputs to

V

CC

or ground either through a resistor or directly Unlike

the inputs unused output should be left floating to allow the

output to switch without drawing any DC current

To reduce voltage transients keep the supply line’s parasit-

ic inductances as low as possible by reducing trace lengths

using wide traces ground planes and by decoupling the

supply with bypass capacitors In order to prevent additional

voltage spiking this local bypass capacitor must exhibit low

inductive reactance You should therefore use high frequen-

cy ceramic capacitors and place them very near the IC to

minimize wiring inductance

X

Keep V

CC

bus routing short When using double sided or

multilayer circuit boards use ground plane techniques

X

Keep ground lines short and on PC boards make them as

wide as possible even if trace width varies Use separate

ground traces to supply high current devices such as re-

lay and transmission line drivers

X

In systems mixing linear and logic functions and where

supply noise is critical to the analog components’ per-

formance provide separate supply buses or even sepa-

rate supplies

X

If you use local regulators bypass their inputs with a tan-

talum capacitor of at least 1 mF and bypass their outputs

with a 10 mFto50mF tantalum or aluminum electrolytic

capacitor

X

If the system uses a centralized regulated power supply

usea10mF to 20F tantalum electrolytic capacitor or a

50 mFto100mF aluminum electrolytic capacitor to de-

couple the V

CC

bus connected to the circuit board

X

Provide localized decoupling For random logic a rule of

thumb dictates approximately 10 nF (spaced within

12 cm) per every two to five packages and 100 nF for

every 10 packages You can group these capacitances

but it’s more effective to distribute them among the ICs If

the design has a fair amount of synchronous logic with

outputs that tend to switch simultaneously additional de-

coupling might be advisable Octal flip-flop and buffers in

bus-oriented circuits might also require more decoupling

Note that wire-wrapped circuits can require more decou-

pling than ground plane or multilayer PC boards

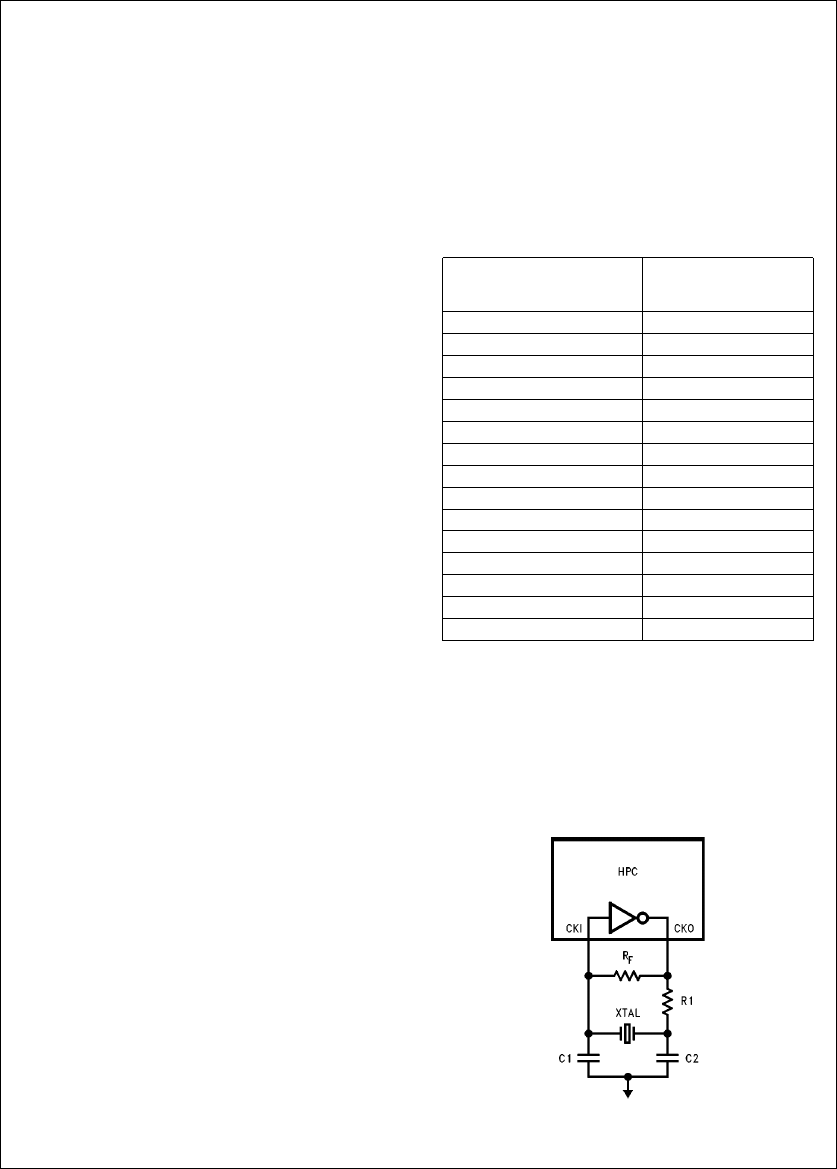

A recommended crystal oscillator circuit to be used with the

HPC is shown in

Figure 29

See table for recommended

component values The recommended values given in

Table V have yielded consistent results and are made to

match a crystal with a 20 pF load capacitance with some

small allowance for layout capacitance

A recommended layout for the oscillator network should be

as close to the processor as physically possible entirely

within 1

distance This is to reduce lead inductance from

long PC traces as well as interference from other compo-

nents and reduce trace capacitance The layout contains a

large ground plane either on the top or bottom surface of

the board to provide signal shielding and a convenient loca-

tion to ground both the HPC and the case of the crystal

It is very critical to have an extremely clean power supply for

the HPC crystal oscillator Ideally one would like a V

CC

and

ground plane that provide low inductance power lines to the

chip The power planes in the PC board should be decou-

pled with three decoupling capacitors as close to the chip

as possible A 10 mF a 01F and a 0001F dipped mica or

ceramic cap should be mounted as close to the HPC as is

physically possible on the board using the shortest leads

or surface mount components This should provide a stable

power supply and noiseless ground plane which will vastly

improve the performance of the crystal oscillator network

TABLE V HPC Oscillator

XTAL

Frequency R

1

(X)

(MHz)

2 1500

4 1200

6 910

8 750

10 600

12 470

14 390

16 300

18 220

20 180

22 150

24 120

26 100

28 75

30 62

R

F

e

33 MX

C

1

e

27 pF

C

2

e

33 pF

XTAL Specifications The crystal usedwas an M-TRON Industries MP-1 Se-

ries XTAL ‘‘AT’’ cut parallel resonant

C

L

e

20 pF

Series Resistance is

25X

25 MHz

40X

10 MHz

600X

2 MHz

TLDD11046–37

FIGURE 29 Recommended Crystal Circuit

27