LOADING PAPER

2-9

2

Printing onto envelopes

Do not use envelopes that have metal clasps, plastic snaps, string closures, windows, linings, self-adhesive

patches or synthetic materials. Attempting to print on these may cause misfeeds, inadequate toner adherence or

other trouble.

Creases or smudging may occur. This is especially true of embossed surfaces and other irregular surfaces.

Under high humidity and temperature conditions the glue flaps on some envelopes may become sticky and be

sealed closed when printed.

Use only envelopes which are flat and crisply folded. Curled or poorly formed envelopes may be poorly printed or

may cause misfeeds.

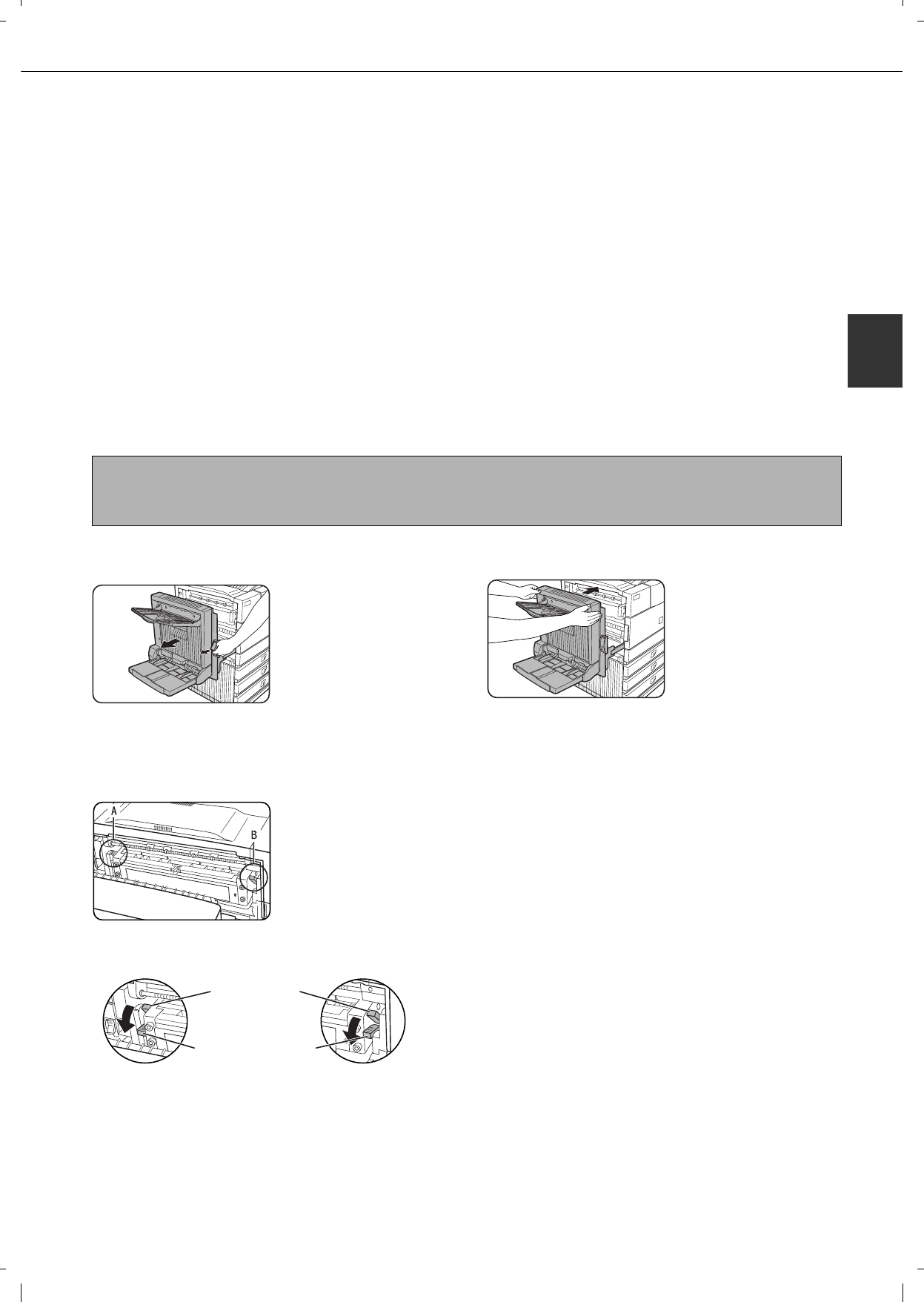

Fusing unit pressure adjusting levers

When feeding envelopes from the multi purpose drawer, damage to the envelopes or smudges on prints may occur

even if envelopes within specification are used. In this case, the problem may be reduced by shifting the fusing unit

pressure adjusting levers from the normal position to the lower pressure position. Follow the procedure below.

1

Unlatch the duplex module and slide it to

the left.

Unlatch the module and

gently move the module

away from the machine.

If the machine is not

equipped with a duplex

module, open the side

cover similarly.

2

Lower the two fusing unit pressure

adjusting levers marked A and B in the

illustration.

3

Gently close the duplex module.

If the machine is not

equipped with a duplex

module, close the side

cover.

NOTE

Be sure to return the lever to the normal position when finished feeding envelopes. If not, inadequate toner

adherence, paper misfeeds or other trouble may occur.

Normal position

Lower pressure position

A: Rear side of

fusing unit

B: Front side of

fusing unit