Chapter 7 Theory of operations

Page 70 STT8000A Product Manual

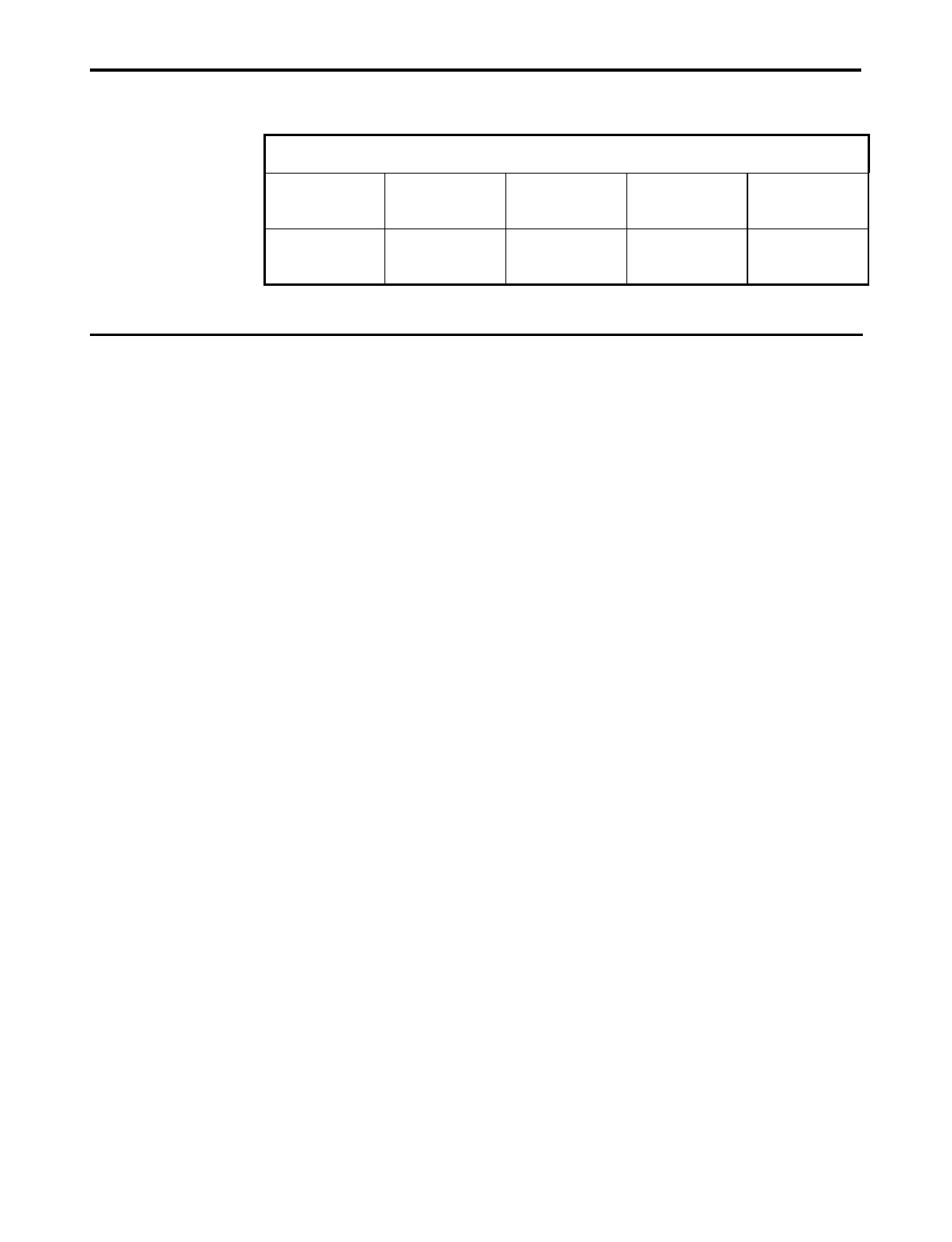

The following table shows clock frequencies used by the STT8000 drive

VCO Frequencies—All Derived from System Clock (42 MHz Crystal Oscillator)

Fundamental

Frequency

28 MHz 28 MHz 28 MHz 24.89 MHz

Channel

Frequency

9.33 MHz 7.00 MHz 4.667 MHz 3.11 MHz

Mechanics

The mechanical package for the STT8000 ATAPI minicartridge drive was designed

to provide all the advantages of easy cartridge loading and unloading while

maintaining the positioning accuracy necessary for high-density data recording. The

orientation of the cartridge is the same as the majority of QIC minicartridge drives in

the field.

Cartridge load mechanism

The cartridge is inserted in the drive by sliding it through the aperture in the bezel

and into a tray mechanism. When fully inserted the back portion of the cartridge

protrudes about 3/4-inch from the aperture. A switch is actuated at this point that

causes a microprocessor to complete the loading operation.

When the tape is in motion, the amber LED on the front panel flashes. The LED is

not lit when the tape is positioned at BOT.

Capstan drive motor assembly

In the STT8000 ATAPI minicartridge drive, the cartridge is driven by the

capstan/belt motor assembly, which is on a linear slide. The cartridge is loaded

against the cartridge drive roller which exerts a net radial dynamic force of 18 to 26

ounces. The motor is a brushless DC drive motor with integral capstan which is

designed to provide maximum reliability.

The motor operates from the 12V nominal supply and moves the tape at speeds

from 35 to 100 inches per second (IPS).

Chassis

The drive mechanism is mounted in a molded frame that provides the mounting

holes for the industry standard 3.5-inch by one inch form factor. A 5.25-inch

mounting kit is an available option. The bezel is a simple snap-on design that is

available in several standard and custom colors. The round, front-panel LED is

amber and indicates tape activity.