13

ProSEAL

®

44 Pouch Board Laminator

TROUBLE SHOOTING GUIDE

Contact your Technical Service

Representative.

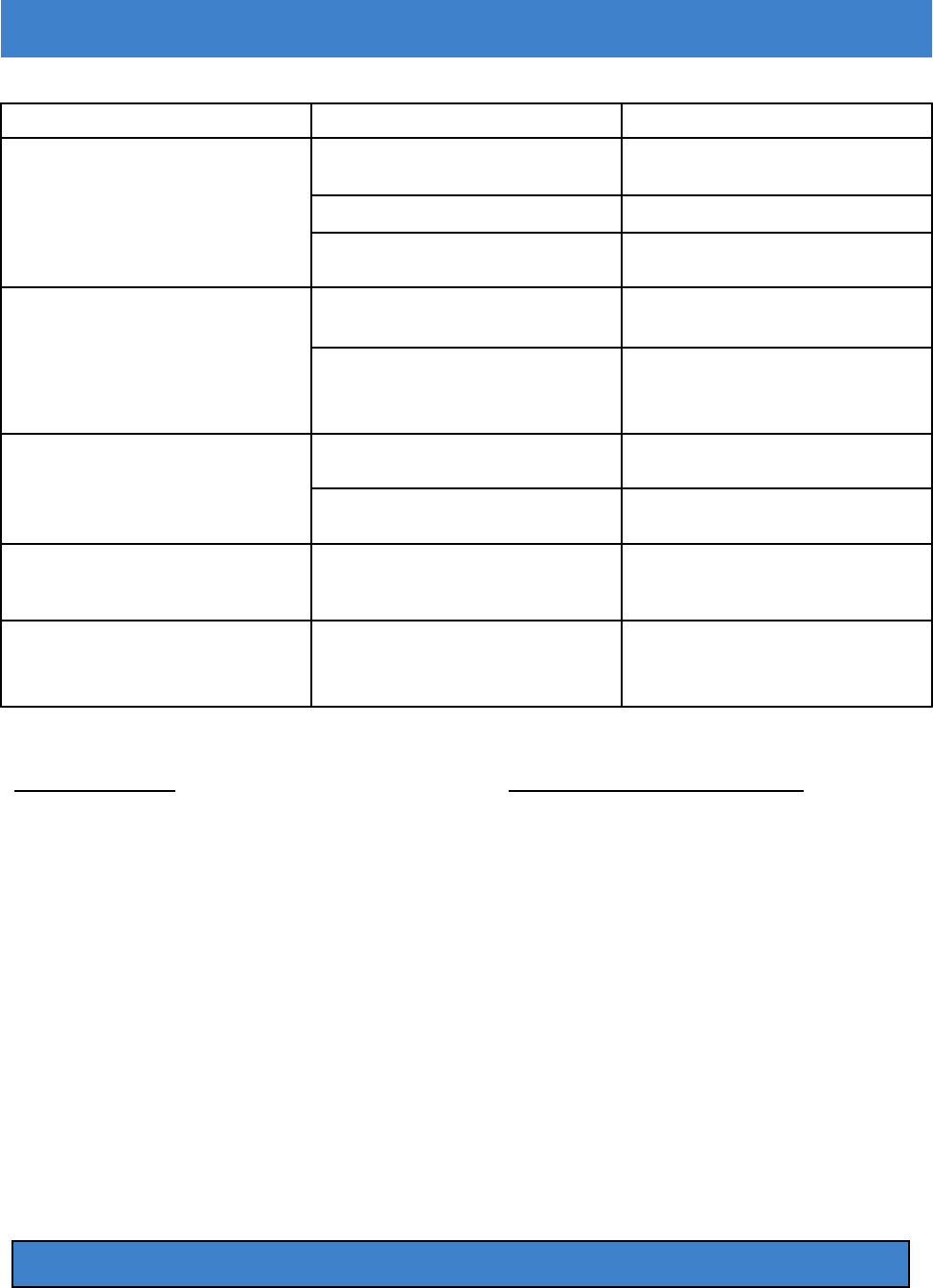

The rollers are not even or parallel.Only one side of the Pouch Board or

Flexible Pouch is coming out fully

laminated.

Contact your Technical Service

Representative.

The roller temperature is too high.The quality of the lamination is poor:

especially laminated Inkjet prints

show bubbles.

Change the nip setting down to the

next thickness.

The roller pressure is too low.

Contract your Technical Service

Representative.

The roller temperature is too low.The quality of the lamination is poor:

silvery areas on dark surfaces are

visible, or the edges of the image are

not sealed well.

Use only ProSEAL Pouch Boards.

Use of other boards will void your

warranty.

Boards of another make are being

used.

Change the nip setting up to the next

or correct thickness.

The pouch board is too thick for the

chosen nip setting.

Pouch Board is not drawn in by the

machine. The motor is making a

louder humming noise and/or it is

stalling. Only after pushing very

hard, the board is accepted.

Reset the main circuit breaker at the

service panel.

The main circuit breaker is tripped.

Replace fuse on rear of machine.The main fuse is blown.

Plug cord into wall outlet.The power cord is not plugged into

the wall outlet.

The LED Indicator does not light

when the main power switch is

turned on.

SOLUTIONCAUSEPROBLEM

Technical Service

If the machine does not reach temperature or

you do not get the results you desire, please

contact your Technical Service

Representative (see rear cover). When

calling for Technical Service, please have

Laminator Serial Number (listed on the

ratings label) available. The ratings label is

located on the rear side of the laminator.

Servicing and replacement parts

Service and maintenance must be performed

fully in accordance with the instructions.

Servicing by any unauthorized technician voids

the warranty. A service technician must use

replacement parts specified by SEAL Graphics.

NOTE! Service Technicians must perform safety

checks after completing any service or repairs to

the laminator.