TECHNICAL SPECIFICATIONS

1.1

Exposure Device Description

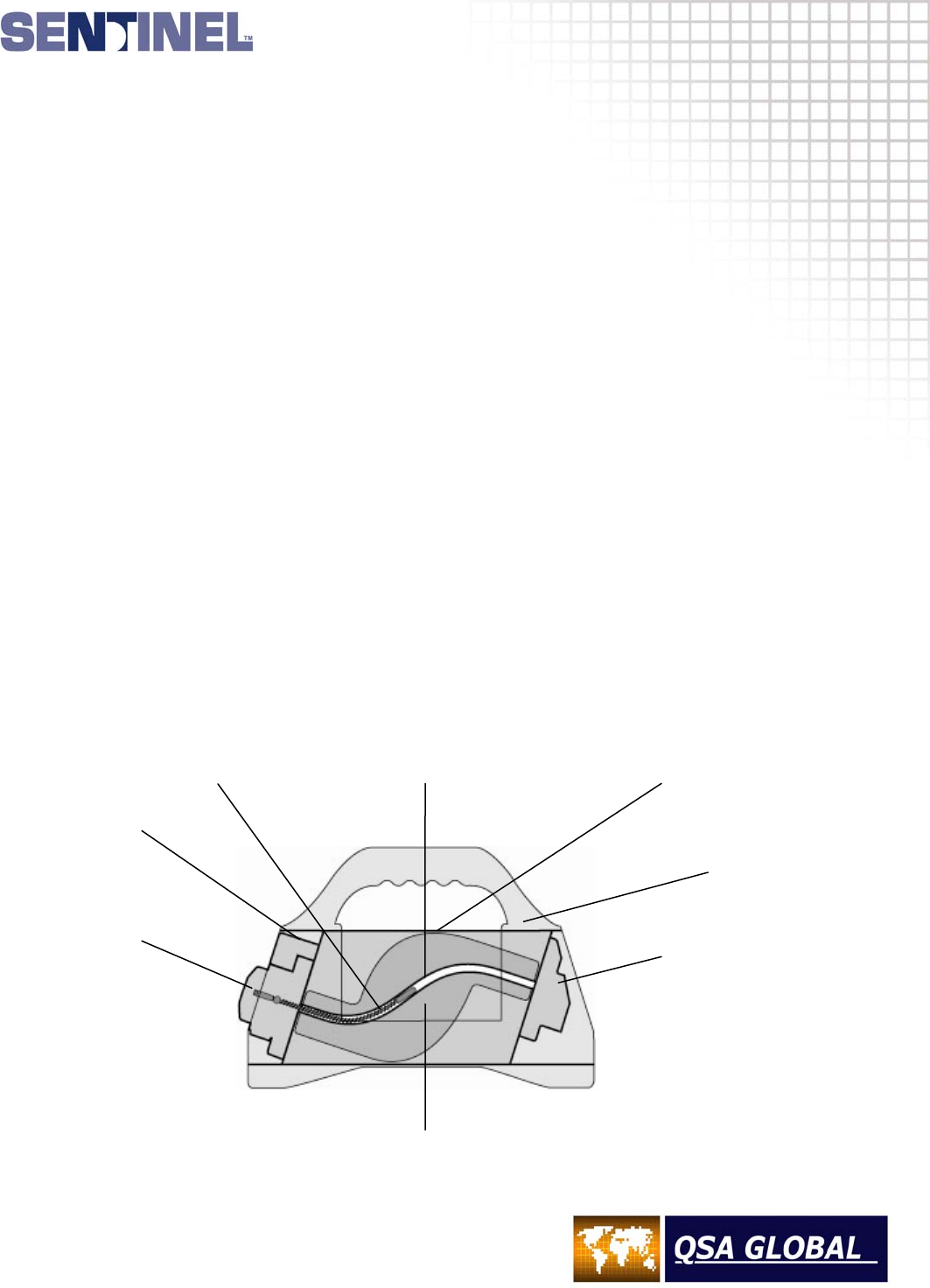

The Model 880Delta, Model 880 Sigma, Model 880 Elite and Model 880 Omega are physically small,

lightweight, portable industrial radiographic exposure devices. The ‘S’ tube design exposure device

consists of a cast depleted Uranium (DU) shield contained and secured within a 300 series stainless steel

tube with stainless steel discs welded at each end to form a cylinder shaped housing. Both discs are

recessed into the stainless steel tube to provide protection for the locking mechanism at the rear side and

the outlet port at the front side.

The welded tubular hosing is oriented horizontally to provide easy access to the locking mechanism and

source assembly connector and to provide easy access to the outlet port for connection of the projection

sheaths. The internal void space of the welded housing is filled with polyurethane foam to prevent the

ingress of water or foreign material but is open to atmospheric pressure. The stainless steel housing

containing the DU shield, locking mechanism, outlet port, protective covers and required labels comprise

the radioactive material transport package.

A plastic jacket surrounds the welded housing and serves as a protective barrier for the labels and

provides the means for carrying and placement during use as a radiographic exposure device. The

Model 880 Delta is identified by a yellow colored jacket. The Model 880 Sigma is identified by a black

colored jacket. The Model 880 Elite is identified by a blue colored jacket and the Model 880 Omega is

identified by a safety orange colored jacket. The plastic jacket incorporates a carrying handle and a base

that is used during radiographic operations but is not required for transportation purposes. The plastic

jacket may be removed for certain applications such as when the exposure device is securely mounted to

a pipe-crawler locomotive or a pipe-liner sled.

The Model 880 Delta, Sigma, Elite and Omega exposure devices are designed, tested, and manufactured

to meet the requirements of ANSI N432-1980, ISO 3999-1:2000(E), IAEA TS-R-1 (1996 Revised),

USNRC 10CFR34, 10CFR71 and 49CFR173 requirements. Additionally, these exposure devices are

designed, manufactured and serviced under an ISO 9001 QA Program and a USNRC 10CFR71, Subpart

H QA Program. The QA program also includes the reporting requirements of USNRC 10CFR21 for

suppliers of source and byproduct materials.

Titanium ‘S’ TubeSource Assembl

y

Plun

g

er Lock

Locking Mechanism

Remote

Control

Connector

Welded Shield Container

Protective

Plastic Jacket with

Carrying Handle

De

p

leted Uranium Shield

Outlet Port

Guide Tube

Connector