1. Maintenance

In order to maintain the optimum performance of this printer and to prevent trouble, maintenance must be carried out

according to the following items.

When performing maintenance, always turn o the power, and take the appropriate measures to orevent static electricity.

1-1. Periodic Maintenance

To ensure long-term and stable printing, periodically clean the modules. It is recommended that you clean every

3 months or every 500,000 lines.

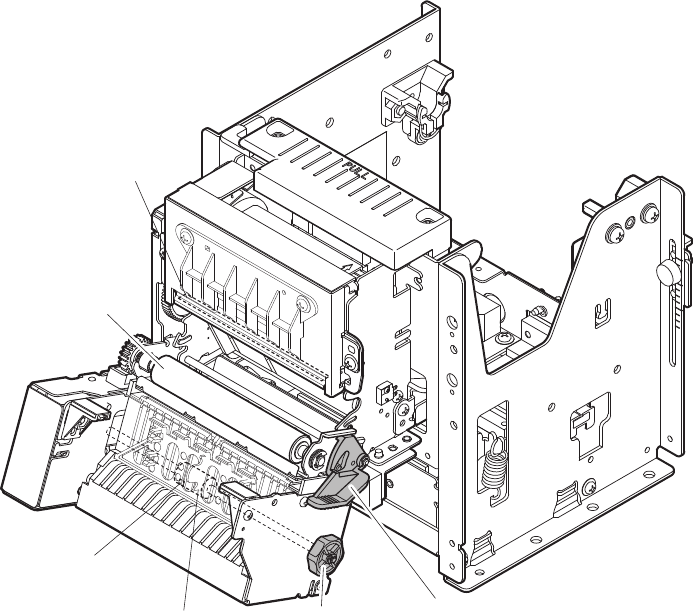

e thermal head and platen can be cleaned by opening the platen unit (including the presenter unit of TUP592) with

the release lever.

•

ermal Head Cleaning Method

To clean the thermal head heating elements, wipe with a cotton swab dampened with an alcohol based cleaner (such

as ethanol or methanol). Also, do not apply excessive force when doing so. Wipe the heating elements gently.

Aer cleaning, check that the alcohol has completely evaporated before closing the platen unit.

•

Platen Cleaning Method

Dampen a so cloth with an alcohol-based solvent(such as ethanol or methanol) and wipe the platen while

slowly turning it. Also, complete wipe away all of the paper dust on the rubber platen. If the cleaning is incom-

plete, there may be problems in paper feeds.

• Presenter Sensor and Peripheral Maintenance Method (only TUP592)

Remove any dirt, dust, or paper cuttings that may be adhering to the presenter sensor or the vicinity. Use a so,

dry cotton cloth, swab or brush to clean. Also, do not apply excessive force when doing so.

• PF Roller Cleaning Method (only TUP592)

To clean the PF roller, dampen a so cloth with an alcohol-based solvent (such as ethanol or methanol) and

clean the PF roller while slowly turning it using the knob. Also, do not apply excessive force when doing so.

Wipe the heating elements gently.

Thermal Head

Platen

Presenter Sensor

PF Roller

Knob

Release Lever

Fig. 2-1 Locations to Perform Periodic Maintenance (TUP592 External View)

- 8 -