83-507-5002 Rev. B

30

Table 4-2: Rear panel Connections and Controls (continued)

Number Item Description

Section

4

Remote Out

connector

RJ-45 type connector, used for daisy-chaining power supplies to

form a serial communication bus.

7.3

7.5

5 J1 Analog

Remote

connector

Connector for remote analog interface. Includes Output Voltage

and Current programming and monitoring signals, Shut-off control

(electrical signal), Enable/Disable control (dry-contact), Power Sup-

ply OK (PS_OK) signal and operation mode (CV/CC) signal.

4.5

6 SW1 Setup

switch

Nine position DIP-switch for selecting remote programming and

monitoring modes for Output Voltage, Output Current and other

control functions.

4.4

7

J2 Remote

sense

connector

Connector for making remote sensing connections to the load for

regulation of the load voltage and compensation of load wire drop.

3.10

3.8.2

8 Blank

Sub-plate

Blank sub-plate for standard units. Isolated Remote Analog pro-

gramming connector for units equipped with Isolated Analog control

option. IEEE connector for units equipped with IEEE programming

option (shown).

Fig. 4.2

9 IEEE switch

Two position DIP-switch for selecting IEEE mode or RS232/RS485

mode when IEEE option is installed.

Fig. 4.2

10

Ground

screw

M4x0.7, 8mm long DBL-

SEMS screw for chassis ground

connection.

Fig. 4.2

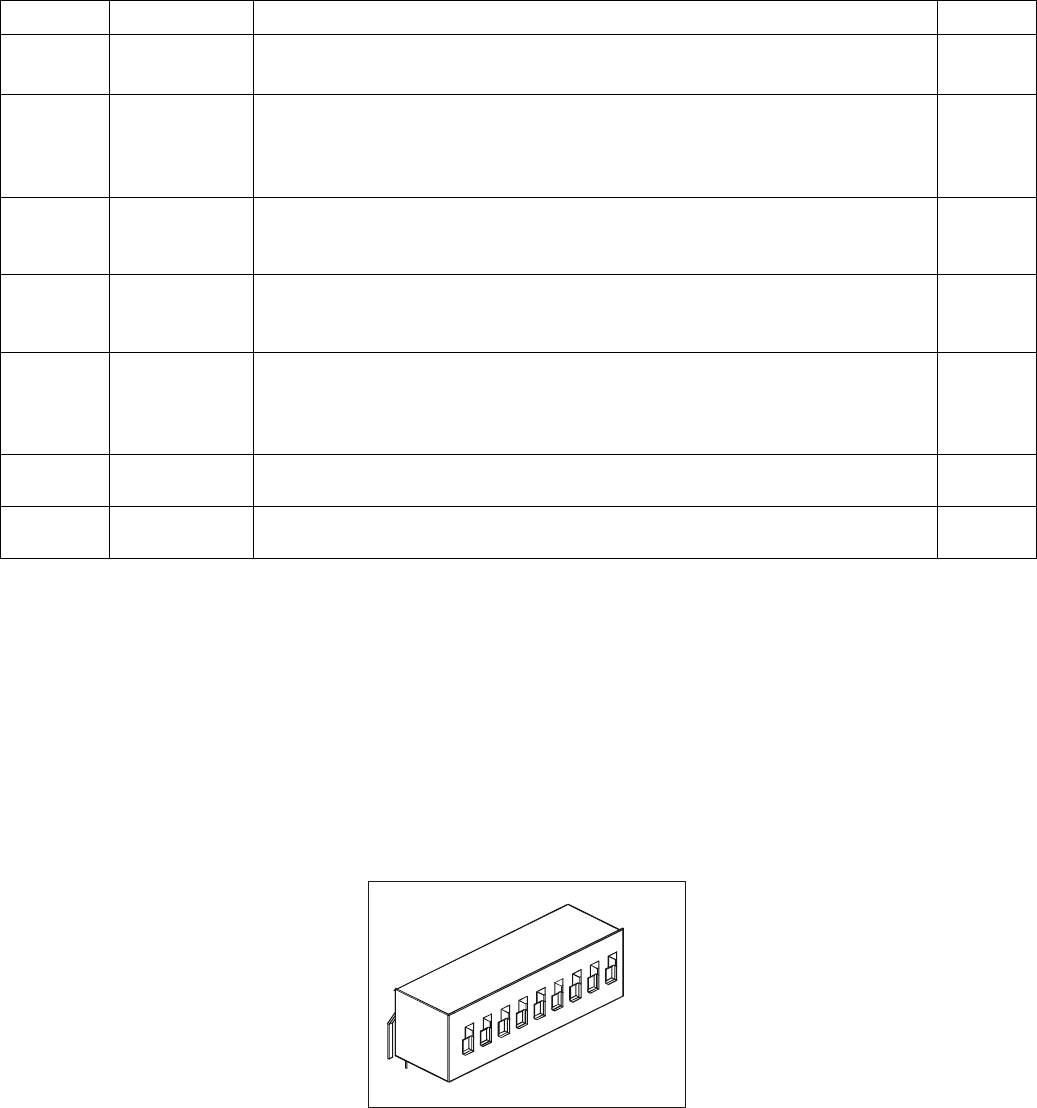

4.4 REAR PANEL SW1 SETUP SWITCH

The SW1 Setup switch (see Fig.4-3) is a 9-position DIP-switch that allows the user to choose the

following:

− Internal or remote programming for Output Voltage and Output Current.

− Remote voltage or resistive programming of Output Voltage and Output Current limit.

− Select range of remote voltage and resistive programming.

− Select range of output Voltage and Output Current monitoring.

− Select the Remote Shut-Off control logic.

− Select between RS232 and RS485 communication interface.

− Enable or disable the rear panel Enable/Disable control (dry contact).

4.4.1 SW1 position function

Refer to Table 4-3 for description of SW1 position functions. The factory default setting is

Down for all positions.

Fig.4-3: SW1 setup DIP-switch

1

2

3

4

5

6

7

8

9