Data Sheet: Maxeta

TM

iFA Series

©2002-2006 TDK Innoveta Inc.

iFA 28V 600W Advance Datasheet 8/3/2006

℡

(

877

)

498-0099

11/19

Thermal Management:

An important part of the overall system

design process is thermal management;

thermal design must be considered at all

levels to ensure good reliability and lifetime

of the final system. Superior thermal design

and ability to operate in severe application

environments are key elements of a robust,

reliable power module.

A finite amount of heat must be dissipated

from the power module to the surrounding

environment. This heat is transferred by the

three modes of heat transfer: convection,

conduction and radiation. While all three

modes of heat transfer are present in every

application, convection is the dominant

mode of heat transfer in most applications.

However, to ensure adequate cooling and

proper operation, all three modes should be

considered in a final system configuration.

The open frame design of the power module

provides an air path to individual

components. This air path improves heat

conduction and convection to the

surrounding environment, which reduces

areas of heat concentration and resulting hot

spots.

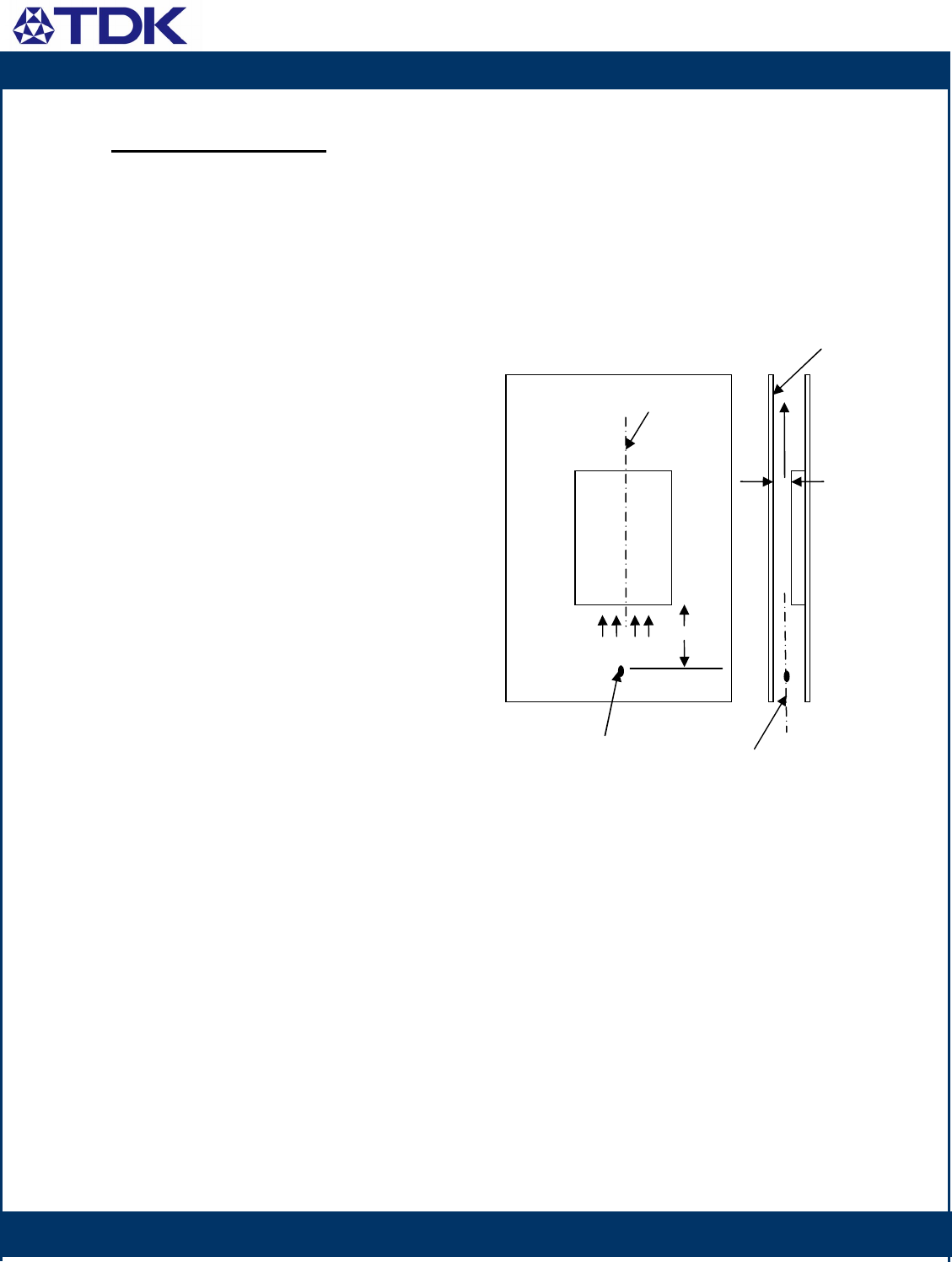

Test Setup:

The thermal performance data

of the power module is based upon

measurements obtained from a wind tunnel

test with the setup shown below. This

thermal test setup replicates the typical

thermal environments encountered in most

modern electronic systems with distributed

power architectures. The electronic

equipment in optical networking, telecom,

wireless and advanced computer systems

operates in similar environments and utilizes

vertically mounted PCBs or circuit cards in

cabinet racks.

The power module, as shown in the figure,

is mounted on a printed circuit board (PCB)

and is vertically oriented within the wind

tunnel. The cross section of the airflow

passage is rectangular. The spacing

between the top of the module or heatsink

(where applicable) and a parallel facing PCB

is kept at a constant (0.5 in). The

power module orientation with respect to the

airflow direction can have a significant

impact on the module’s thermal

performance.

Thermal De-rating

: For proper application

of the power module in a given thermal

environment, output current de-rating curves

are provided as a design guideline in the

Thermal Performance section for the power

module of interest. The module temperature

should be measured in the final system

configuration at the location indicated in the

thermal measurement location figure to

ensure proper thermal management of the

power module. In all conditions, the power

module should be operated below the

maximum operating temperature shown on

the de-rating curve. For improved design

margins and enhanced system reliability, the

power module may be operated at

temperatures below the maximum rated

operating temperature

.

A

IRFLOW

A

ir Velocity and Ambient

Temperature

Measurement Location

A

I

R

F

L

O

W

12.7

(0.50)

Module

Centerline

A

ir Passage

Centerline

A

djacent PCB

76 (3.0)

Wind Tunnel Test Setup Figure Dimensions are

in millimeters and (inches).