2. PRINTER SETUP

ENGLISH VERSION EO1-33047

2.3 Loading the Media

E2-10

2.3 Loading the Media

(Cont.)

When the optional Cutter Module is fitted, the media is automatically cut.

Insert the leading edge of the media into the Media Outlet of the Cutter

Module.

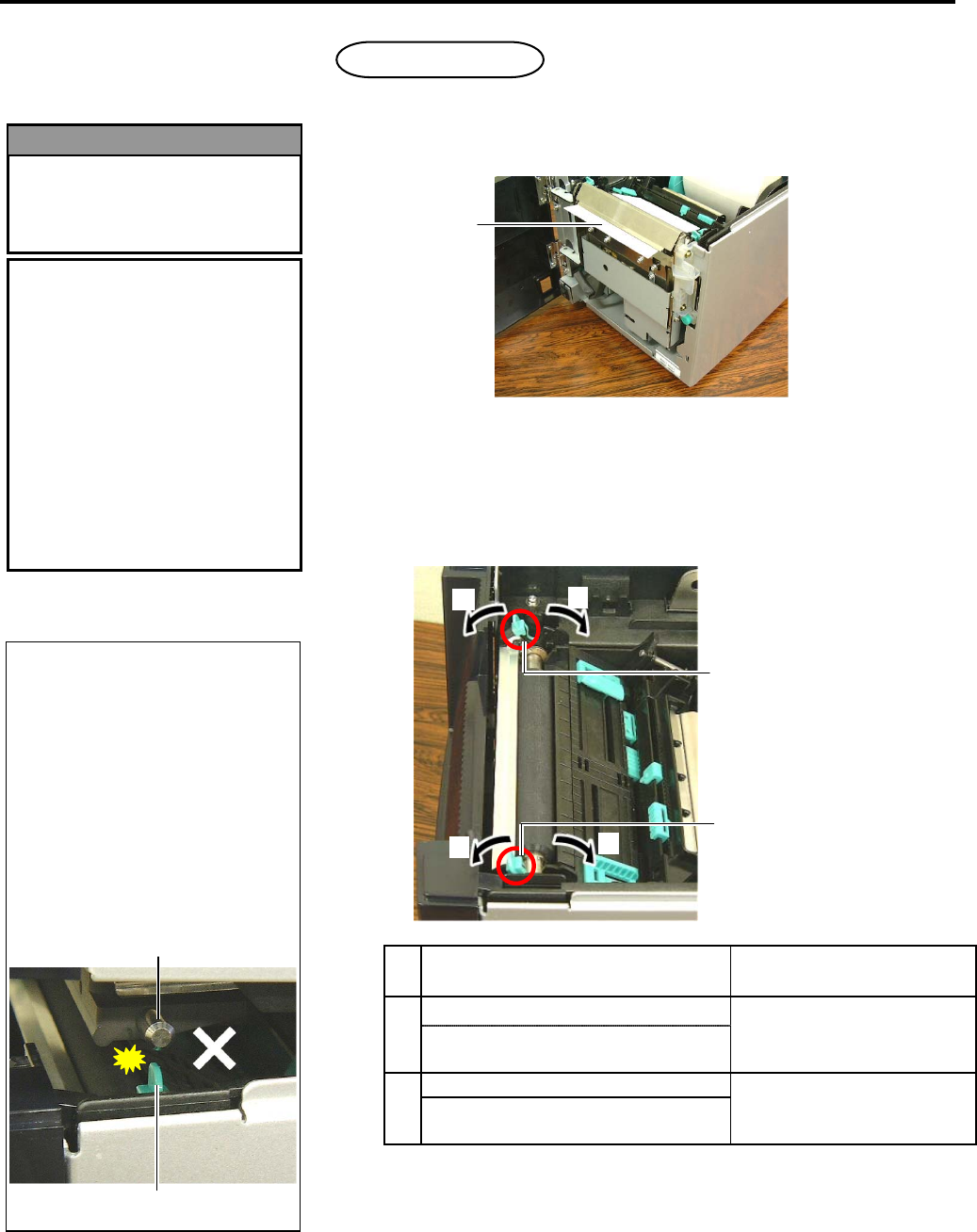

13. Change the print head pressure according to the thickness of the

media to be used, by using the Head Pressure Adjust Lever.

Media type or thickness

Head Pressure

Adjustment Lever

Label or Thin media

c

If a clear print cannot be obtained,

change the position to

d.

Move the levers toward the

front of the printer.

Tag paper or Thick paper

d

If a clear print cannot be obtained,

change the position to

c.

Move the levers toward the

back of the printer.

14. If the loaded media is direct thermal media (with a chemically

treated surface), the media loading procedure is now completed.

Close the Top Cover.

If the media is normal media, it is also necessary to load a ribbon.

Refer to Section 2.4 Loading the Ribbon.

Media

Cut mode

(

O

p

tion

)

CAUTION

!

1. When using a label stock, be

sure to cut the gaps. Cutting

labels will cause the glue to

stick to the cutter, which may

affect the cutter quality and

shorten the cutter life.

2. Use of tag paper which

thickness exceeds specified

value may affect the cutter

life. For the specification of

the media, refer to Section

7.1 Media.

The cutter is sharp, so care

must be taken not to injure your

fingers when handling the

cutter.

WARNING!

Head Pressure

Adjustment Lever

c

d

c

d

NOTES:

1. Be sure to set both Head

Pressure Adjustment Levers in

the same direction. Failure to

do this may cause blurred

printing.

2. Do not leave the Head Pressure

A

djustment Levers positioned at

the middle. When closing the

Top Cover, they block the Print

Head Positioning Shaft, and the

Top Cover cannot be closed.

Print Head Positioning Shaft

Head Pressure Adjust Lever

Head Pressure

Adjustment Lever