7. SUPPLY SPECIFICATIONS ENGLISH VERSION EO1-33056

7.2 Ribbon

E7- 4

7.2 Ribbon

Please make sure that the ribbon being used is approved by TOSHIBA TEC. The warranty does not apply to any

problem caused by using non-approved ribbons.

For information regarding TOSHIBA TEC approved ribbon, please contact a TOSHIBA TEC service

representative.

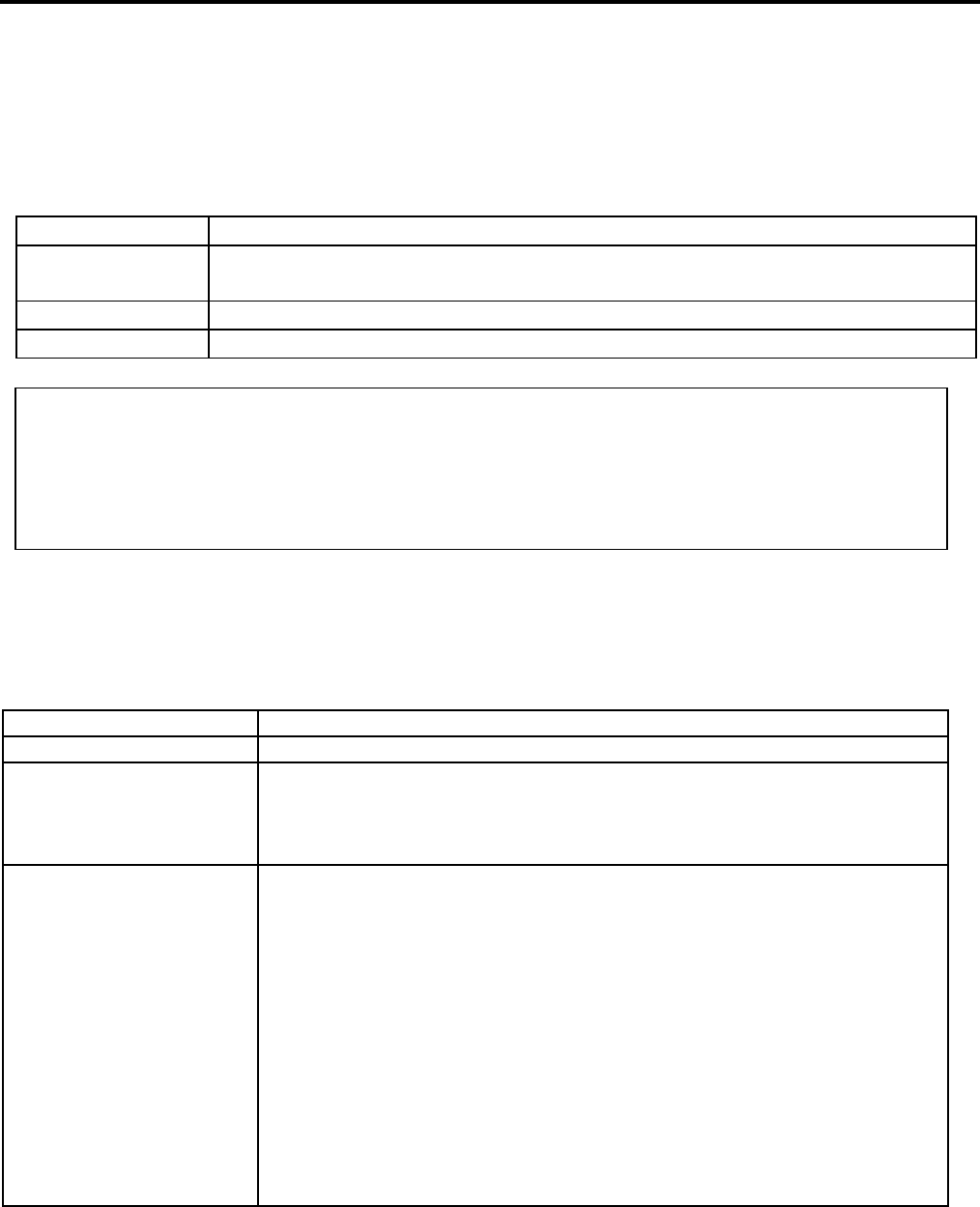

Type Spool type

Width 115 – 185 mm

115 – 160 mm (Print Speed: 8"/sec)

Length 300 m (within ∅72 mm)

Outside Diameter ∅72 mm (max.)

7.3 Recommended Media and Ribbon Types

(1) Media type

Media type Description

Vellum paper and labels General use for low cost applications.

Coated paper

Matt coated paper

General use including applications that require small letters and/or symbols.

Glossy coated paper

Used where a high-grade finish is required

Plastic films

Synthetic film (Polypropylene, etc.)

This water-proof and solvent-resistant material has high physical strength

and low-temperature resistance, but poor heat resistance (dependant upon

material). This material can be used for labels stuck to recyclable

containers, so it can be recycled in the same process.

PET film

This water-proof and solvent-resistant material has high physical strength,

and low-temperature resistance as well as heat resistance. This material is

used for many applications, especially where high durability is required.

Mode/serial plate labels, caution labels, etc.

Polyimide

This material gives the best performance on heat resistance (greater than

PET film). It is often used for PCB labels as it can withstand passage

through a solder bath.

N

OTES:

1. To ensure print quality and print head life use only TOSHIBA TEC specified ribbons.

2. Too much difference in width between media and ribbon may cause ribbon wrinkles. To avoid ribbon

wrinkles use a ribbon for proper media width shown in the above table. Do not use a ribbon that is narrower

than media.

3. When discarding ribbons, please follow the local rule.