Visual Inspection of Mechanical Connections

152315 Rev C 4–3

Visual Inspection of Mechanical Connections

To perform a visual inspection of the PV100S mechanical connections:

Visual Inspection of Electrical Connections

To perform a visual inspection of the PV100S electrical connections:

1. Ensure that the AC and DC Disconnect Switches, as well as any utility

interconnect circuit breakers or main disconnect switches, are opened.

❐

2. Ensure all anchor bolts and any required seismic bracing is properly

tightened and in place.

❐

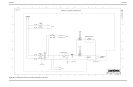

3. Remove the wiring access panels and front covers from the AC

Interface/Transformer assembly and Main Inverter Inductor Enclosure.

❐

4. Remove the latches and open the doors of the Main Inverter Enclosure,

the AC and DC Interface Enclosures, and Communication Enclosure

and inspect.

❐

5. Verify all wire conduit fittings and connections are properly tightened. ❐

1. Ensure that the AC and DC disconnect switches, as well as any utility

interconnect circuit breakers or main disconnect switches, are opened.

❐

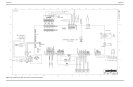

2. Ensure all conductors and wiring connections interfacing with the

PV100S are tightened to the correct torque value.

For specific torque values, see Table 3-1, “AC Terminal Wire Gauge,

Bolt Size, and Torque Values” on page 3–12 and Table 3-2, “DC

Terminal Wire Gauge, Bolt Size, and Torque Values” on page 3–12.

❐

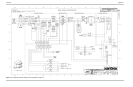

3. Verify AC power conductors terminated at TB4-A, TB4-B, TB4-C

within the Main Inverter Enclosure are terminated correctly and

properly sequenced.

❐

4. Verify the AC power conductors terminated at S1-2T1, S1-4T2, S1-6T3

within the AC Interface Enclosure are terminated correctly and properly

sequenced.

❐

5. Verify DC power conductors terminated at TB3-1, TB3-2, TB3-3 within

the DC Interface Enclosure are terminated correctly and properly

polarized.

❐