Introduction

7

NOTICE

Risk of equipment damage. Batteries should be cleaned with a dry cloth or a cloth lightly

moistened with water. Do not use cleaners on the batteries. Solvents can make the battery

cases brittle.

Because individual battery characteristics are not identical and may change over time, the UPS

module is equipped with circuitry to equalize battery cell voltages. This circuit increases charging

voltage to maintain flooded type battery cells at full capacity.

Matching Battery Cabinets—Optional

Although the individual battery cells are sealed (valve-regulated) and require only minimal

maintenance, the Battery Cabinets should be given a periodic inspection and electrical check. Checks

should be performed at least annually to ensure years of trouble-free service.

Voltage Records: With the Battery Cabinet DC circuit breaker closed and the connected UPS

operating, measure and record battery float voltage. With the DC circuit breaker open, measure and

record the nominal (open circuit) voltage. Both these measurements should be made across the final

positive and negative terminal lugs. Compare these values with those shown below. The recorded

nominal voltage should be no less than the value shown; while the recorded float voltage should be

within the range shown. If a discrepancy is found, contact Liebert

®

Services.

Power Connections: Check for corrosion and connection integrity. Inspect wiring for discolored or

cracked insulation. Clean and/or retighten as required. Refer to torque specifications in Table 3.

Battery Cell Terminals: Check for discoloration, corrosion and connection integrity. Clean and

tighten if necessary. Note that when installing a new battery, the initial torque value is 5 lb.-in. more

than the retorque value. Table 3 shows battery retorque values.

If the system uses a different model battery, contact Liebert

®

Services for the required torque value.

To access battery cell terminals, disconnect the inter-tier cable and two shelf retaining screws. Once

disconnected, insulate (with protective boot or electrical tape) the cables to prevent accidental shorts.

The battery shelf can now be pulled out. Tighten each terminal connection to the retorque value.

When replacing a battery, the terminal connections must be cleaned and tightened. Disconnect and

insulate the cables connected to the battery. Secure each battery shelf with retaining screws when

maintenance is complete.

!

WARNING

Risk of electric shock, explosive reaction, hazardous chemicals and fire. Can cause equipment

damage, personal injury and death.

Do not use equalize charging with valve-regulated, lead-acid batteries, such as those in

Liebert Battery Cabinets. Refer to the battery manufacturer’s manual, available on the

manufacturer’s Web site, for specific information about equalize charging.

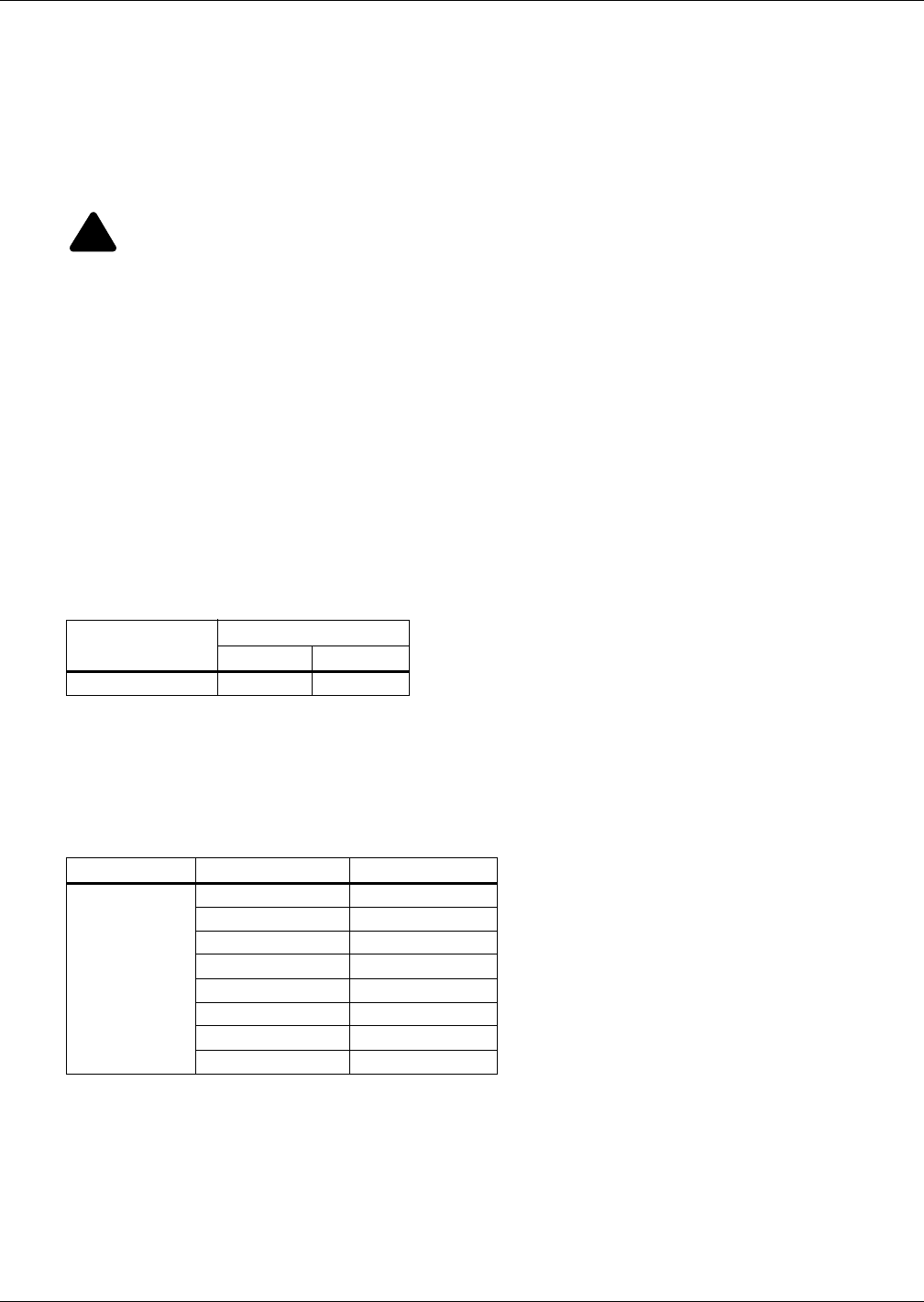

Table 2 Battery voltage, nominal and float

Number of Cells

Battery Voltage, VDC

Nominal Float

144 324 316 - 331

Table 3 Battery retorque values

Battery Mfr. Battery Model # Retorque Value

Enersys

HX205-FR 65 in-lb

HX300-FR 65 in-lb

HX330-FR 65 in-lb

HX400-FR 65 in-lb

HX500-FR 65 in-lb

HX540-FR 65 in-lb

16HX800F 100 in-lb

16HX925F 100 in-lb