TM200 Service Manual

- 20 -

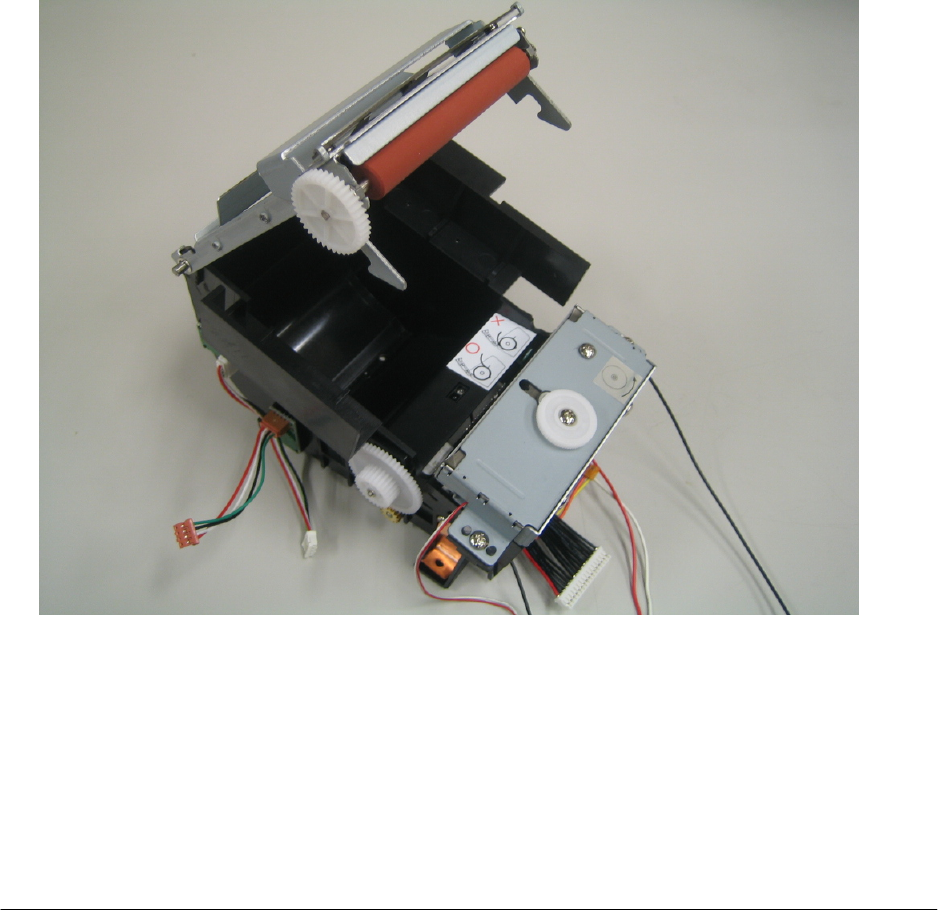

Printer Mec

hanism

Thermal head Module

T

he the

r

mal

head

is d

e

sig

ned

so it

s heat

i

ng

el

em

e

n

t i

s

posi

ti

oned

wher

e it

comes i

nto

cont

act

wi

th t

he p

l

at

en. T

he r

o

ll

pa

per

wrap

ped

ar

ound

th

e pl

ate

n

is k

e

pt

in

cont

act

wit

h

the

ther

m

a

l

hea

d

’

s heat

i

ng

el

em

e

n

t at

a p

r

escr

ibed

pr

essure,

and

pr

int

i

ng

is

p

e

rfor

med whe

n

heat is

g

enera

t

ed

b

y

the

heat

i

ng

element

.

P

r

i

n

ti

ng

is

p

e

rf

orm

e

d

a

cc

o

rd

in

g

t

o

th

e

fo

ll

ow

i

n

g st

e

p

s:

1.

T

he pr

int

sig

n

al

send

s a

pr

escri

b

e

d

ene

rgi

zi

ng p

u

lse

to t

he el

ect

rod

e

s tha

t

co

rr

espond

to

ea

ch d

o

t t

o be pr

int

e

d

.

2.

Resist

ors a

t

ea

ch el

ectro

d

e

gener

at

e heat

.

3.

T

he heat ener

gy g

ener

ated

by t

he resisto

r

s i

s

tr

ansmit

ted to the r

o

ll

p

a

per

sur

f

a

ce

t

h

rou

g

h

t

he pr

ot

ecti

v

e

lay

e

r t

o

t

he pa

per

’

s he

at-sensi

t

i

v

e

lay

e

r, c

ausi

n

g co

lor

a

ti

on

o

f

the p

a

p

e

r.

F

i

g

u

re 2

.2 F

r

ame cove

r open

Th

e

p

a

p

e

r o

u

t

l

e

t o

f

th

e

p

r

i

n

te

r

is c

overe

d

,

an

d

ev

e

n

if p

a

p

e

r o

u

t

pu

t be

c

o

m

e

s bl

o

c

ke

d

f

o

r

so

m

e

r

e

ason,

ther

e i

s

en

ough

ro

om in

t

he sp

ace

b

e

t

w

een the

pl

aten

and

fr

ame cov

e

r

for

acc

u

mula

ti

on

of t

w

o o

r

t

h

ree n

o

rmal

le

ngth

recei

pt

s (the

leng

th o

f

one sheet

is a

ssum

e

d

t

o

be 80mm or le

ss

).

T

h

is r

e

d

u

ces the

chance

of rece

ip

t p

a

per

b

e

coming

b

e

nt an

d

of t

he

p

r

i

n

t p

i

t

ch becomin

g

unev

en.

Pa

per

tha

t

ac

cumula

tes c

a

n be easi

ly

pul

l

ed

ou

t of t

he

p

r

i

n

ter

afte

r t

he pa

per

outlet

is o

p

ened

.