Section 2: Sensor and Sampling Techniques

5

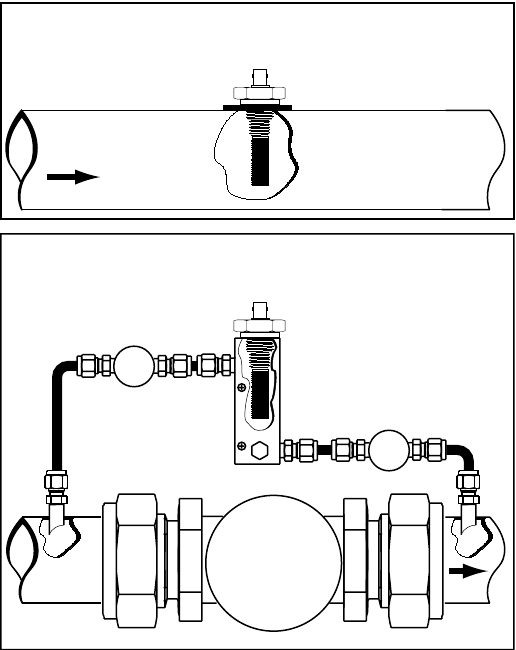

2.3.1 In-situ Installation

In-situ installation is recommended only for measurements where the gas pressure is expected to

vary little, the gas is expected to be free of contaminants, the gas temperature is within the operat-

ing specifications of the sensor, and there is no chance of liquids coalescing. Examples of applica-

tions suited for in-situ installations are: pure gases, output of desiccant dryers (for instrument air),

glove boxes, etc. For most other applications in-situ installation should be avoided for the follow-

ing reasons:

• Sample conditioning is almost always necessary to avoid exposure of the sensor to liquid

water and other contaminants, such as hydrocarbons, which may damage the sensor or affect

accuracy over time.

• Variations in line pressure affect the reading of the sensor because dewpoint varies with pres-

sure.

• If the gas line is under pressure, it is more likely that water condensation occurs which may

damage the sensor.

• Under a pressurized system removal of the sensor without the installation of isolation valves

can be dangerous.

If in-situ installation is required, bypass mounting is preferable; make sure to install the sensor at

the upper surface of the gas line to minimize its exposure to liquid water, should condensation

occur, the XTR65W sensor is best suited for these applications. Also consider the need to isolate

(depressurize) before installing or removing the sensor.

The sensor measures the dewpoint at whatever pressure it is at. The instrument is equipped with a

pressure correction feature which allows reporting the dewpoint at a different pressure.

Main

Gas Line

Safety shut-off Valve

Bypass

Control

Valve *

Safety shut-off Valve

Bypass Installation, Sensor

Measuring at Line Pressure

In-Line Installation, Sensor

Measuring at Line Pressure

Main

Gas Line

NOT RECOMMENDED

Sample Cell

* maintain differential pressure to provide adequate flow through sample cell