XDT User’s Manual

6

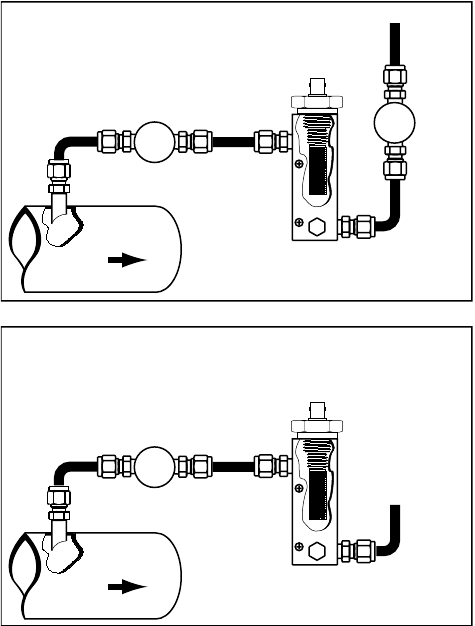

2.3.2 Extractive Installation

For extractive installations we recommend our sample system ESS, which may be equipped with

a variety of features, such as: isolation valve, coalescing or particulate filter, pressure regulator,

calibration sample injection or extraction port, pressure gauge, flow meter, weatherproof enclo-

sure. Refer to the ESS literature for more information.

If the resources to make your own sample system are available, the following two diagrams may

be used as a guideline to configure a simple system.

It is generally recommended to measure at ambient pressure for the following reasons:

• The readings will not be affected by variations in line pressure.

• The risk of exposing the sensor to liquid water is significantly reduced.

• ppm readings are computed for a pressure of one atmosphere (1 bar); and have to be corrected

using software in the instrument, or a pressure monograph, or calculator if the sensor is mea-

suring at different pressures.

If readings at line pressure are necessary, it is recommended to measure at ambient pressure and to

use the instrument’s pressure compensation feature to calculate the dewpoint at line pressure.

Refer to Viewing Dewpoint Mode section 3.4.4.1.

Please make sure that:

• The sample is taken from the upper surface of the main gas line. This avoids problems with

contamination. The sample should be taken away from pipe line walls where flow rates may

be low, and dewpoint changes may lag.

• For dewpoints dryer than -40°F, use stainless steel tubing only. For dewpoints -40°F and wet-

ter, copper tubing is acceptable. Do not use plastic, rubber or tygon tubing under any circum-

stances, as measurements would be incorrect and/or response time slow due to water retention

Exhaust

Regulator or

Needle Valve

Safety shut-off Valve

Extractive Installation, Sensor

Measuring at Line Pressure

Exhaust

Regulator or

Needle Valve

Extractive Installation, Sensor

Measuring at Ambient Pressure

Sample Cell Sample Cell

Main

Gas Line

Main

Gas Line