XDT User’s Manual Appendices

46

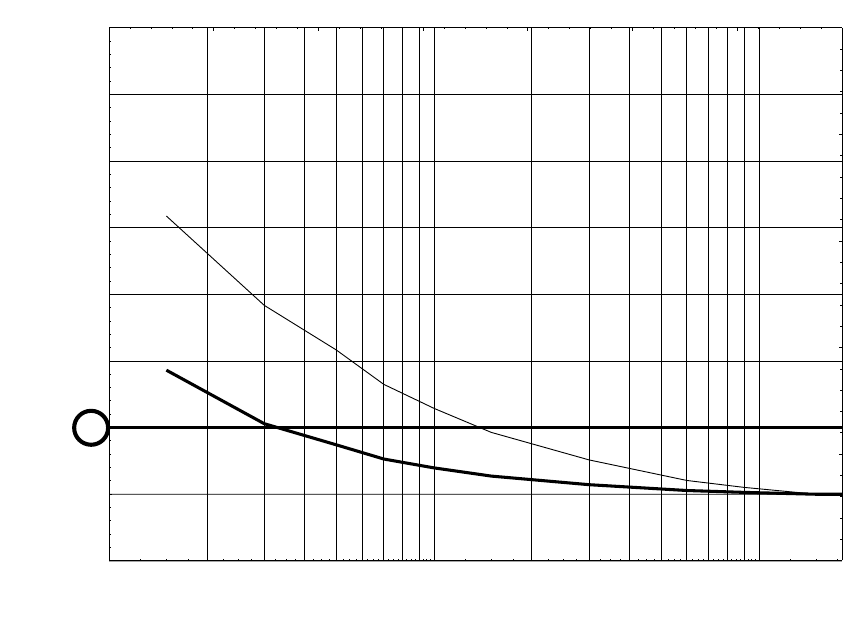

Appendix G: Dewpoint Response time Analysis

Manufacturers of dewpoint sensors will make unbelievable claims of speed. But without support-

ing data revealing the conditions under which the measurements were made, such as flow rate,

temperature, the dewpoint at which the test was performed, and most importantly the units of

measure. This last aspect can be extremely deceiving, consider the following example.

At Xentaur we have performed a variety of tests to determine the response time of ours as well as

the competitor’s sensors. For this discussion let’s consider a step change of -40°C to -60°C dew-

point, in other words a challenging but typical dry-down. An XTR-100 sensor w/SS sintered filter

was placed in an electro-polished stainless steel manifold, the temperature was 23°C and the sam-

ple flow rate was 3 LPM. The dewpoint was generated with a computer controlled mass flow

valve gas dilution dewpoint generator, and was verified with a NIST and NPL calibrated MBW

chilled mirror. The system was allowed to achieve equilibrium at -40°C dp overnight, then the

dewpoint was abruptly changed to -60°C, the change is depicted below as time 0.

The graph below shows the percent change of recorded dewpoint (°C), the same data is also

shown in percent change of the recorded dewpoint converted to ppmV. It is immediately obvious

how a sensor that has response times exceeding ten minutes can be claimed to have response time

of 3 minutes, simply by manipulating the units of measure. The logarithmic relationship between

dewpoint and ppmV makes the ppmV reading appear faster. Since the response time is stated in

percent change, the units of measure are automatically hidden from the audience.

30

40

-50

˚C = 50%

60

70

80

90

-60

˚C = 100%

110

1

2

3

4

5

6

7

8

9

10

20

30

40

50

60

70

80

90

100

%

c

h

a

n

g

e

o

f

p

p

m

V

c

o

n

v

e

r

t

e

d

m

e

a

s

u

r

e

m

e

n

t

%

c

h

a

n

g

e

o

f

˚

C

m

e

a

s

u

r

e

m

e

n

t

Time (minutes)

Percent Change