F-36 PRO Laminator Operation Manual

Operation

© GBC Pro-Tech 1999 January

3-3

-#

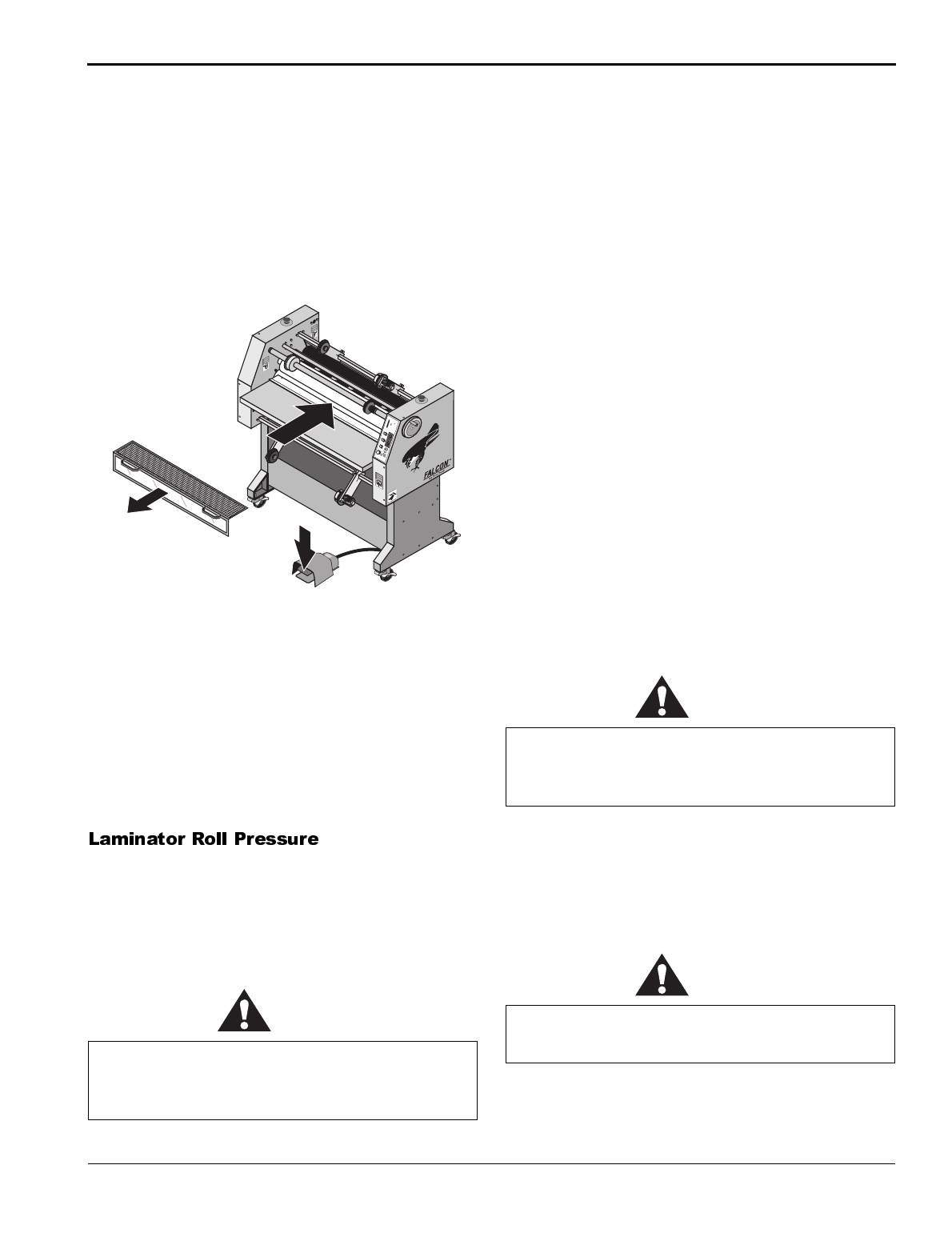

The footswitch on the F-36 PRO Laminator operates

much like the accelerator on an automobile. When the

mechanical guard is removed, use the footswitch to

feed material into the laminator at the rate you select by

pressing the footswitch. The more pressure you apply,

the faster the rolls turn. When you remove pressure

from the footswitch, the rolls stop.

Figure 3-4: Using the Footswitch

Setup of the F-36 PRO Laminator is quick and straight-

forward when instructions are followed exactly.

To adjust the nip, please see

Section 4: Maintenance

and Troubleshooting

.

Use only the minimum amount of roll pressure needed

to accomplish the task. While higher pressure can make

the adhesive bond faster, excess pressure can damage

the rolls. Wrinkles and bubbles have causes that gener-

ally cannot be cured by applying more pressure.

CAUTION

A typical roll pressure for soft substrates such as Foam-

core or Orca Board is 1/4 revolution of the laminating

roll crank.

A typical roll pressure for hard substrates is 1/2 revolu-

tion of the laminating roll crank.

A typical roll pressure for encapsulation is 1/2 revolu-

tion of the laminating roll crank.

*$#.

Film is loaded on the appropriate unwinds. Loading

and aligning the film are discussed later in this section.

For applications such as encapsulation, film is fed from

both the top and bottom feed unwinds.

The process of loading and aligning film is the same

for both the top and the bottom unwinds. There are two

important points to remember when loading film:

1. The adhesive side of the film must be oriented

away (on the outside) from the laminating roll.

Otherwise it will immediately bond to the roll,

creating a major clean-up project.

Films have a shiny side and a dull side. The dull

side is the one with the adhesive. The dull side

should ALWAYS face outward from the laminat-

ing roll.

CAUTION

2. The film must be centered on the unwind for best

performance. This is vital when two films are fed

together. If the two films are not aligned, feed

problems, wrinkles and other assorted troubles will

occur.

CAUTION

Excess pressure can damage the laminating rolls.

Minimum laminator roll pressure is consistent

with good results.

W

A

R

N

IN

G

A

C

H

T

U

N

G

MIS

E EN

G

ARDE

N

O

T

A

U

S

E

M

E

R

G

E

N

C

Y

S

T

O

P

A

R

R

E

T

D

'

U

R

G

E

N

C

E

N

O

T

A

U

S

E

M

E

R

G

E

N

C

Y

S

T

O

P

A

R

R

E

T

D

'

U

R

G

E

N

C

E

1

8

16

4

8

1

2

10

8

6

4

2

0

5

0

7

5

1

0

0

1

2

5

1

5

0

1

7

5

2

0

0

2

2

5

2

5

0

2

7

5

3

0

0

O

U

T

H

I

L

O

P

R

O

T

E

C

H

°

F

0

0

1

-

1

3

3

5

0

7

5

1

0

0

1

2

5

1

5

0

1

7

5

2

0

0

2

2

5

2

5

0

2

7

5

3

0

0

O

U

T

H

I

L

O

P

R

O

T

E

C

H

°

F

0

0

1

-

1

3

3

p

s

i

1

0

0

9

0

8

0

7

0

6

0

5

0

4

0

3

0

2

0

1

0

k

P

a

7

0

0

6

3

0

5

6

0

4

9

0

4

2

0

3

5

0

2

8

0

2

1

0

1

4

0

7

0

W

A

R

N

I

N

G

A

C

H

T

U

N

G

M

I

S

E

E

N

G

A

R

D

E

©

1

9

9

4

H

a

z

a

r

d

C

o

m

m

u

n

i

c

a

t

i

o

n

S

y

s

t

e

m

s

,

I

n

c

.

8

0

0

-

7

4

8

-

0

2

4

1

Remove

Guard

Feed

Material

Into Nip

W

A

R

N

I

N

G

A

C

H

T

U

N

G

M

I

S

E

E

N

G

A

R

D

E

Press

Footswitch

(variable

speed)

Always mount the film so that the adhesive side

faces outward from the laminating roll. This

prevents hours of roll cleaning.

Carefully align the two films being fed into the

nip. If not, you will obtain poor results.