F-36 PRO Laminator Operation Manual

Specifications

© GBC Pro-Tech 1999 January

6-1

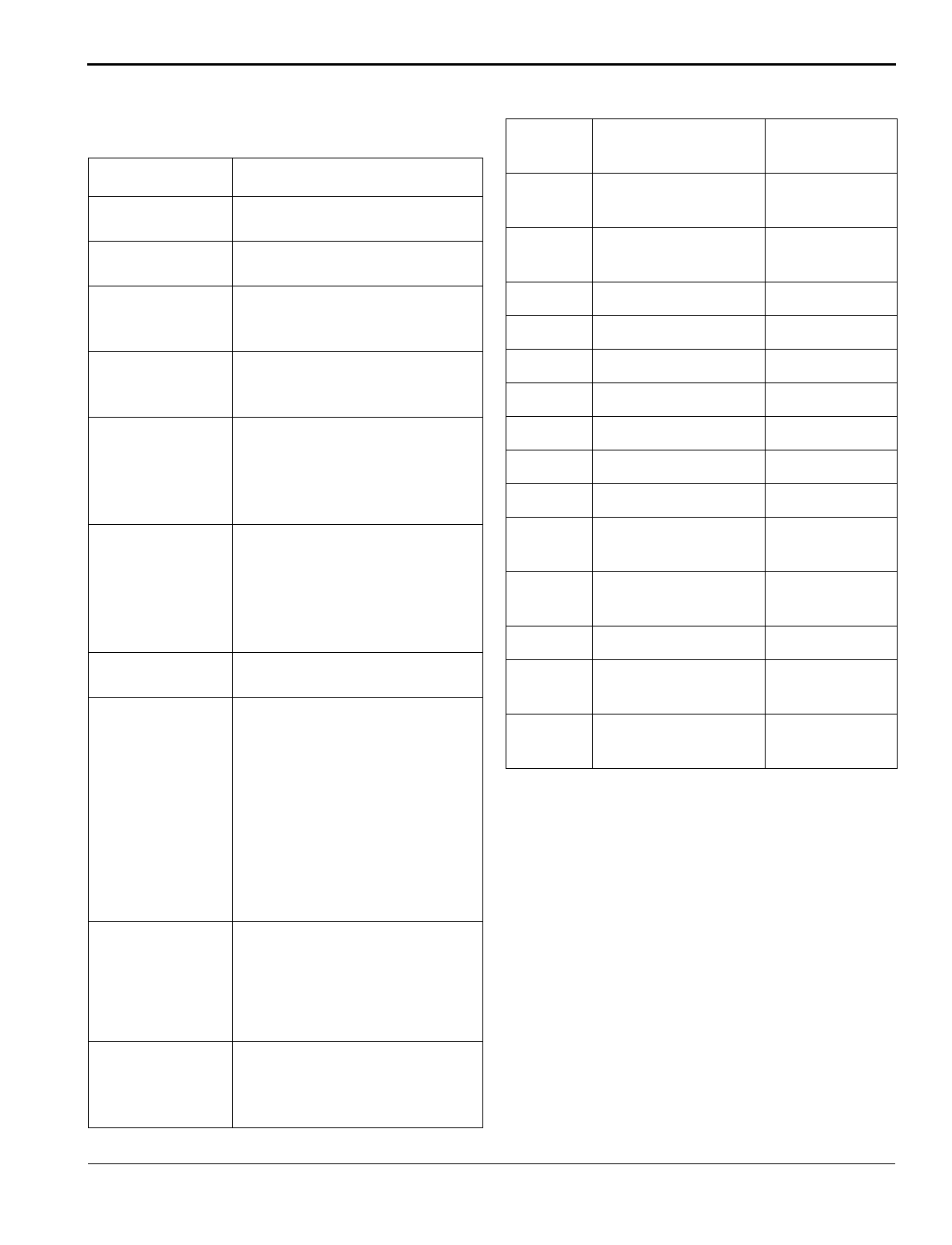

Table 6-1: F-36 PRO Laminator Specifications

Table 6-2: Replacement Parts

Characteristic

Specifications

Dimensions

(L x D x H)

56" x 31" x 56"

(1.42 x .79 x 1.42m)

Weight Uncrated: 300 lbs (136 kg)

Crated : 500 lbs (225 kg)

Laminating Rolls 42" (1.06m) roll face with high

release surface, upper and lower

rolls internally heated

Laminating

Opening

1.5" (3.8 cm) maximum opening

controlled with infinitely vari-

able hand crank

Laminating

Material

Uses heat activated and pressure-

sensitive materials 0 - 39"

(99.6 cm) wide on a 3" (7.6 cm)

ID core, 10" (25.4 cm) maximum

diameter

Laminating

Speeds

0 to 18 fmp (o to 5.5 mpm) with

variable speed, reversible action,

start and stop controlled either

through the instrument panel or

with the variable speed foot-

switch

Encapsulating

Features

Pull rolls and cooling fans for

uniform flat cooling

Safety Features • Mechanical guard on infeed

• All electrical and moving

mechanical parts are located

in bolted cabinets

• Redundant circuit protected

safety shielding

• Hand crank for laminating

roll movement

• Emergency stop buttons with

a reset button circuit

Options • Unwind for rolled prints

• Rewind for rolled prints

• Vacuum table

• Outfeed Slitters

• Outfeed Table

Installation

Requirement

220VAC 50 or 60 Hz single

phase, 30A or, in Europe, 3

phase, 240/400 VAC with 20A

per phase

Part

Number

Description Recommended

Quantity

001-374 Assembly, Force

Gauge PCB

1

001-504 Assembly, Force

Sensor

1

001-528 Relay Board 1

001-134 Temperature Control 1

425-000 Motor 1

690-001 Roll, Main 1

690-002 Pull Roll, Upper 1

690-003 Pull Roll, Lower 1

189-000 Heater, Round 1

240-120 Thermocouple, J-

type, 72"

1

214-000 Microswitch, Safety,

Interlock

1

220-160 Motor Controller 1

220-110 Barrier Board, Motor

Control

1

186-135 Fuse, Ceramic 20A

(Motor Board)

1