6

2.2 Wall Switch Button Operation

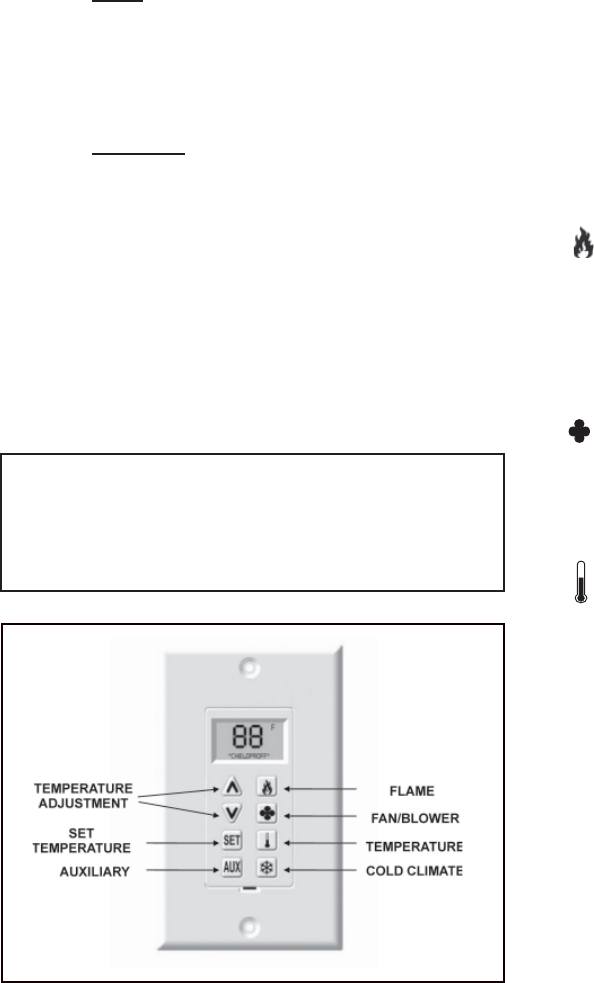

(Refer to Figure 7)

Flame Button

• Button Press: Unit On / Flames High, Turns on auxiliary

power

• Button Press: Flames Low

• Button Press: Unit Off / Flames Off, Turns off auxiliary

power

Fan / Blower Button

• Button Press: Fan High (“3”)

• Button Press: Fan Medium (“2”)

• Button Press: Fan Low (“1”)

• Button Press: Fan Off

Temperature Button

• Button Press will toggle between Automatic and Manual

Operation

• Press and Hold the button for 3 seconds to toggle between

Fahrenheit and Centigrade Temperature Display.

Automatic Operation: Controller will monitor temperature

and control unit according to the set point.

Manual Operation: Controller will not automatically change

settings.

SET

Set Temperature Button

• Button Press: Displays Set Point

• Use Up and Down Arrows to Adjust Set Point

• Press Set Button to Store New Set Point

Temperature Set Point can be adjusted between the ranges of:

45-90

0

Fahrenheit or 7-32

0

Centigrade

NOTE: The controller will turn off the fi replace at 2

0

F over

set point and turn it back on at 2

0

F below set point.

Up and Down Arrows

• Push to adjust set point temperature under automatic

control.

AUX

Auxiliary Button

• Button Press: Turns on auxiliary power

• Button Press: Turns off auxiliary power

Can be operated independently of all functions.

2.0 Operating Instructions

For units WITH factory installed rocker switch.

The ON/OFF rocker switch on the fi replace (located near

the gas valve) must be in the “OFF” position for use with

the WSK-MLT system. The ON/OFF rocker switch will NOT

function with this device on Intellifi re (IPI) models except

during a power outage.

For units WITHOUT factory installed rocker switch.

The ON/OFF rocker switch now installed on the fi replace

must be in the OFF position for use with the IPI or stand-

ing pilot system. The ON/OFF rocker switch will only be

used to control the fi replace in a no-power condition. For

standing pilot systems use the rocker switch to turn the

fi replace on and off. When power is restored switch the

rocker switch to OFF. For IPI system refer to “Operation

Under Battery Power” for instructions.

After all connections are made and the control box is

grounded, plug power cord into the fi replace junction box.

The wall switch will be functional at this time.

Figure 7.

<>

2.1 Setting Flame Height/manifold pressure

(To be done by a qualifi ed service technician). Upon initial

power-up of this device, valve pressure must be set for

fl ame adjustment.

• Loosen output pressure tap on valve and connect with

pressure manometer.

• Press fl ame button once (Fig. 7); fi replace will light with

fl ames on high.

• Turn solenoid clockwise to increase pressure, counter-

clockwise to decrease pressure until manifold pressure

on high is 3.5” water column for natural gas (NG), 10.0”

water column for propane (LP).

• Once pressure is achieved spin jam-nut on solenoid stem

tight against regulator face to prevent rotation. Do not

overtighten.

• Press fl ame button twice to turn fi replace off.

• Remove manometer tube and tighten or close pressure

tap. Use a soap solution to carefully check the pressure

tap for leaks.

NOTE: The temperature displayed by the wall switch may

take up to 30 minutes to stabilize on initial power-up.

NOTE: Check control box and assure switch is in the “OFF”

position. This switch is only used on Intellifi re (IPI) control

systems under battery operation.