2-14

4078-00X

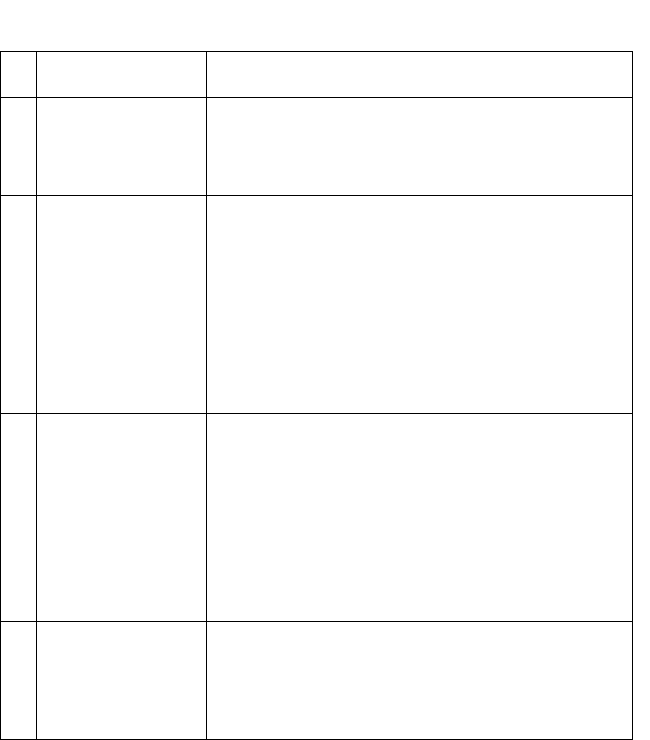

5 Maintenance

Station

Intermittent nozzle failures can be caused by worn

parts in the maintenance station. Perform the

“Maintenance Station Service Check” on page 2-8,

then return to this check.

6 Paper Feed Ink smudging and smearing can be caused by

paper problems or problems in the paper feed

area.

Check the following:

• Correct type of paper is being used. Also check

the paper for curl or wrinkles.

• Feed rollers for wear, dirt, or looseness.

• Gearsforwearorbinds.

• Paper path for obstructions.

7 Carrier Transport Blurred print and voids can be caused by problems

in the carrier transport area. Check the following:

• Carrier transport belt for wear.

• Carrier guide rod for wear or dirt.

• Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301. Do not

lubricate the carrier guide rod.

• Idler pulley parts for wear, damage, or

looseness.

8 Alignment Uneven vertical lines can be adjusted by

performing the bidirectional alignment. The user is

directed, through the Printer Control program, to

perform the bidirectional printing alignment, when

replacing a print cartridge.

FRU / Function Action